Polyurethane/ liquid-based composite explosion-proof structure and preparation method thereof

An explosion-proof structure, polyurethane technology, applied in blasting and other directions, can solve the problems of secondary fragmentation damage, self-weight, poor mobility, etc., and achieve the effect of increasing energy absorption value, reducing transmission intensity, and prolonging transmission duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

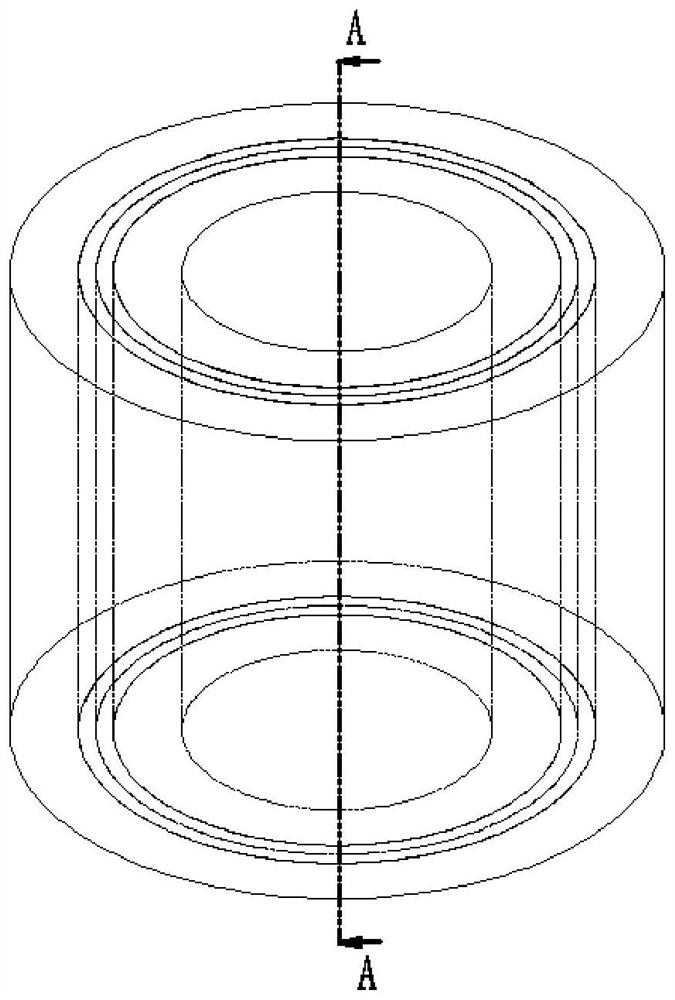

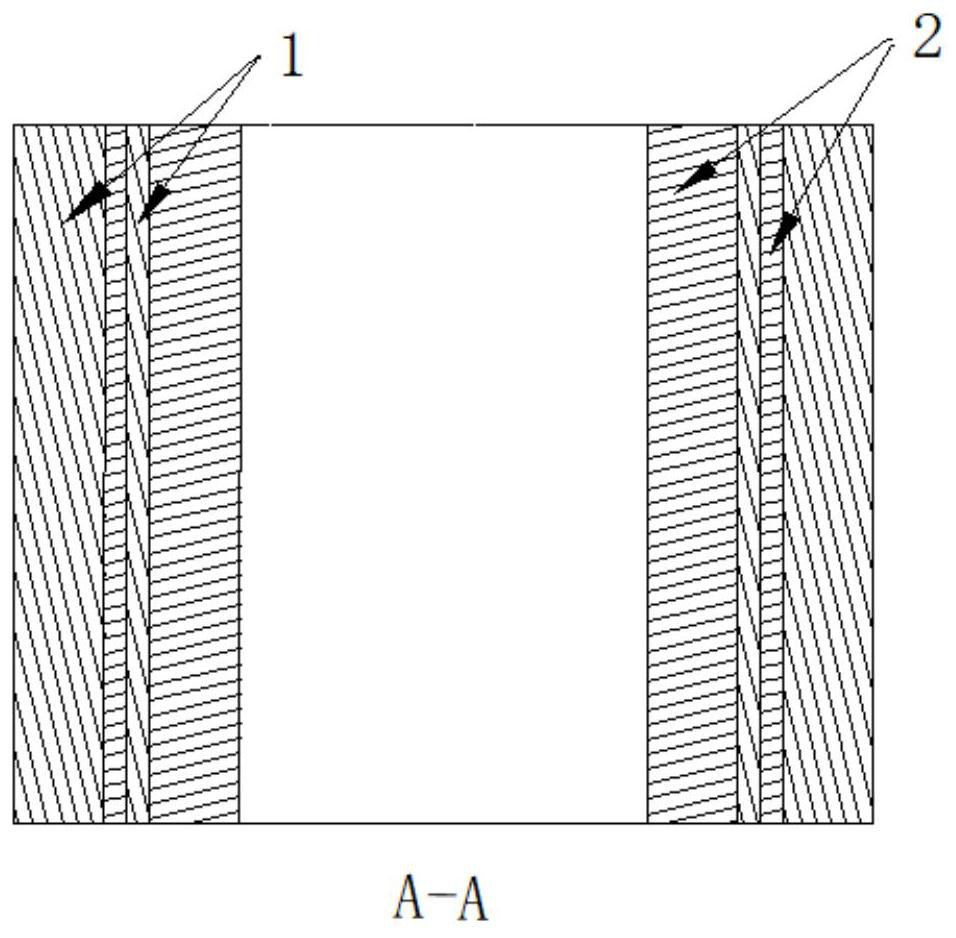

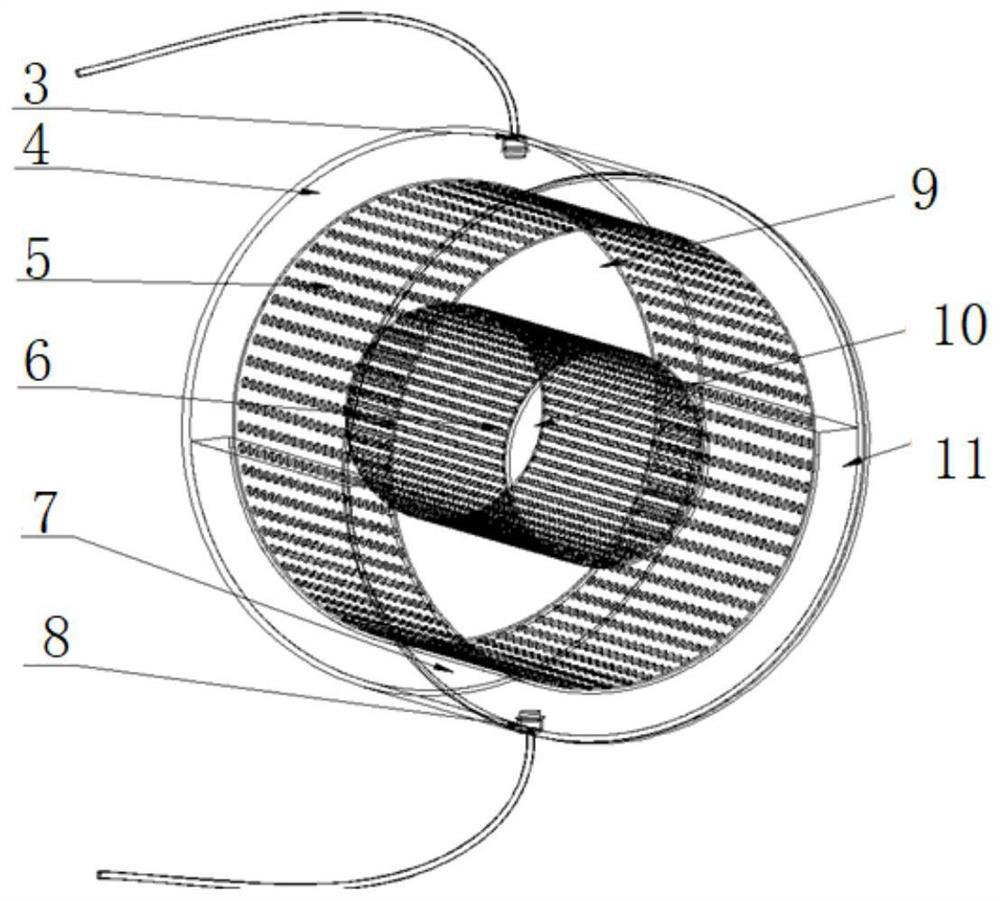

[0033] This embodiment provides a composite explosion-proof structure based on polyurethane / liquid. The composite explosion-proof structure is a structure made of multi-layer cylindrical rings. When explosion-proof, explosives are located inside the ring structure. The liquid-filled polyurethane layer 2 and the liquid layer 1 are arranged at intervals, the number of layers is even, the innermost layer is the liquid-filled polyurethane layer 2, and the outermost layer is the liquid layer 1.

[0034] Such as figure 1 , figure 2 As shown, the composite explosion-proof structure in this embodiment adopts four layers, which are polyurethane layer 2 filled with liquid, liquid layer 1, polyurethane layer 2 filled with liquid, and liquid layer 1 from the inside to the outside. The polyurethane foam matrix of the polyurethane layer 2 filled with liquid contains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com