Laminated Coil Parts

一种线圈部件、层叠型的技术,应用在变压器/电感的零部件、分层产品、电气元件等方向,能够解决自由度变低、强度降低、很难充分地降低透磁率和介电常数等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the laminated coil component of the present invention will be described. However, the present invention is not limited to the following embodiments, and can be appropriately changed and applied within a range that does not change the gist of the present invention. Moreover, it is this invention that combined two or more of each preferable structure described below.

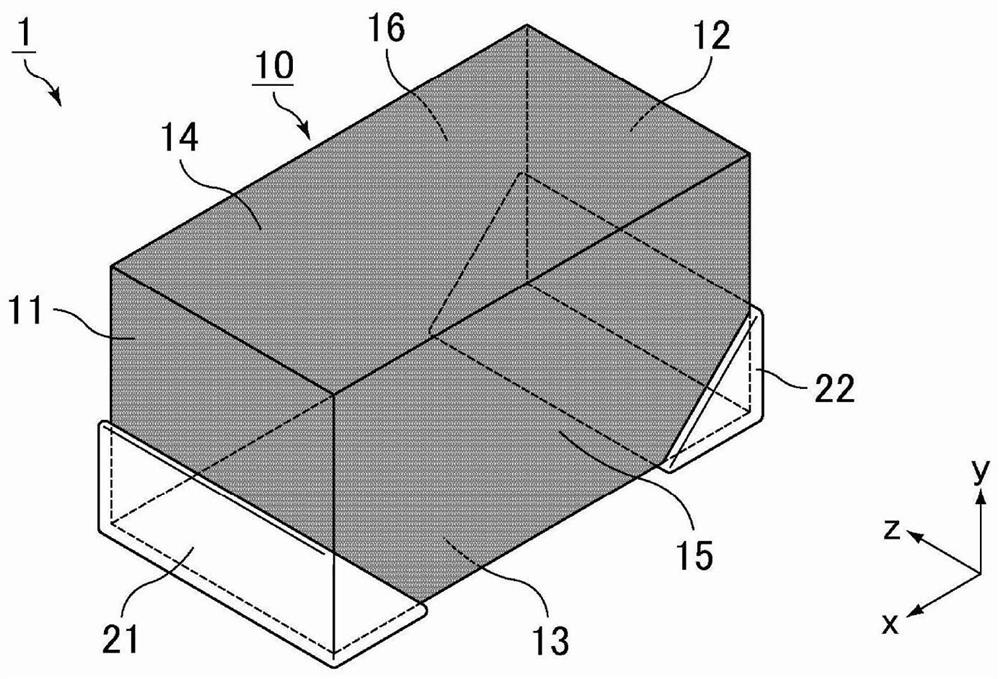

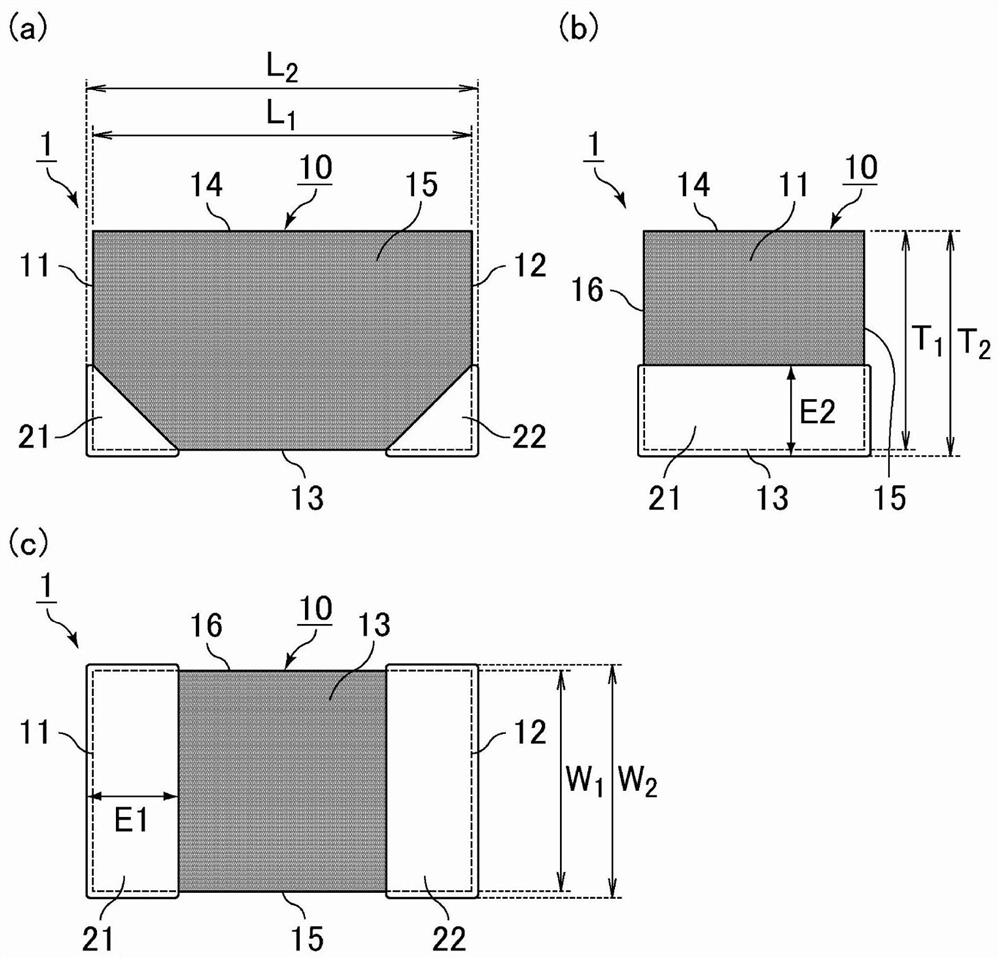

[0018] figure 1 It is a perspective view schematically showing a laminated coil component according to one embodiment of the present invention. figure 2 (a) is figure 1 A side view of the laminated coil assembly shown, figure 2 (b) is figure 1 The front view of the laminated coil part shown, figure 2 (c) is figure 1 Bottom view of the laminated coil component shown.

[0019] figure 1 , figure 2 of (a), figure 2 (b) of and figure 2 The laminated coil component 1 shown in (c) includes a laminated body 10 , a first external electrode 21 , and a second external electrode 22 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com