Multiple pipe baffle type energy saving boiler

A clapboard type boiler technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of easy vaporization of water pipes, low heat conduction efficiency, and small receiving area, so as to enhance market competitiveness, Fast heat conduction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

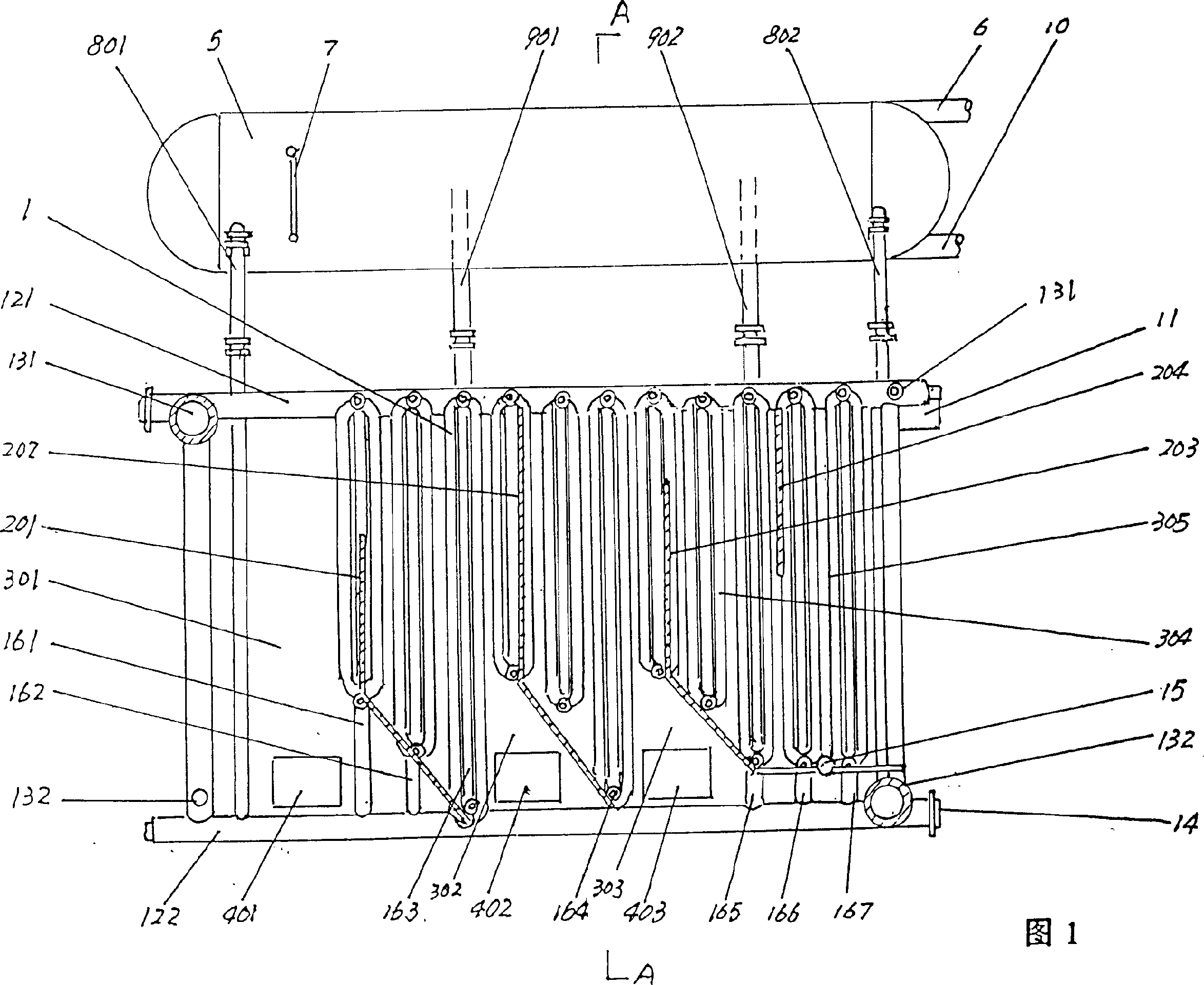

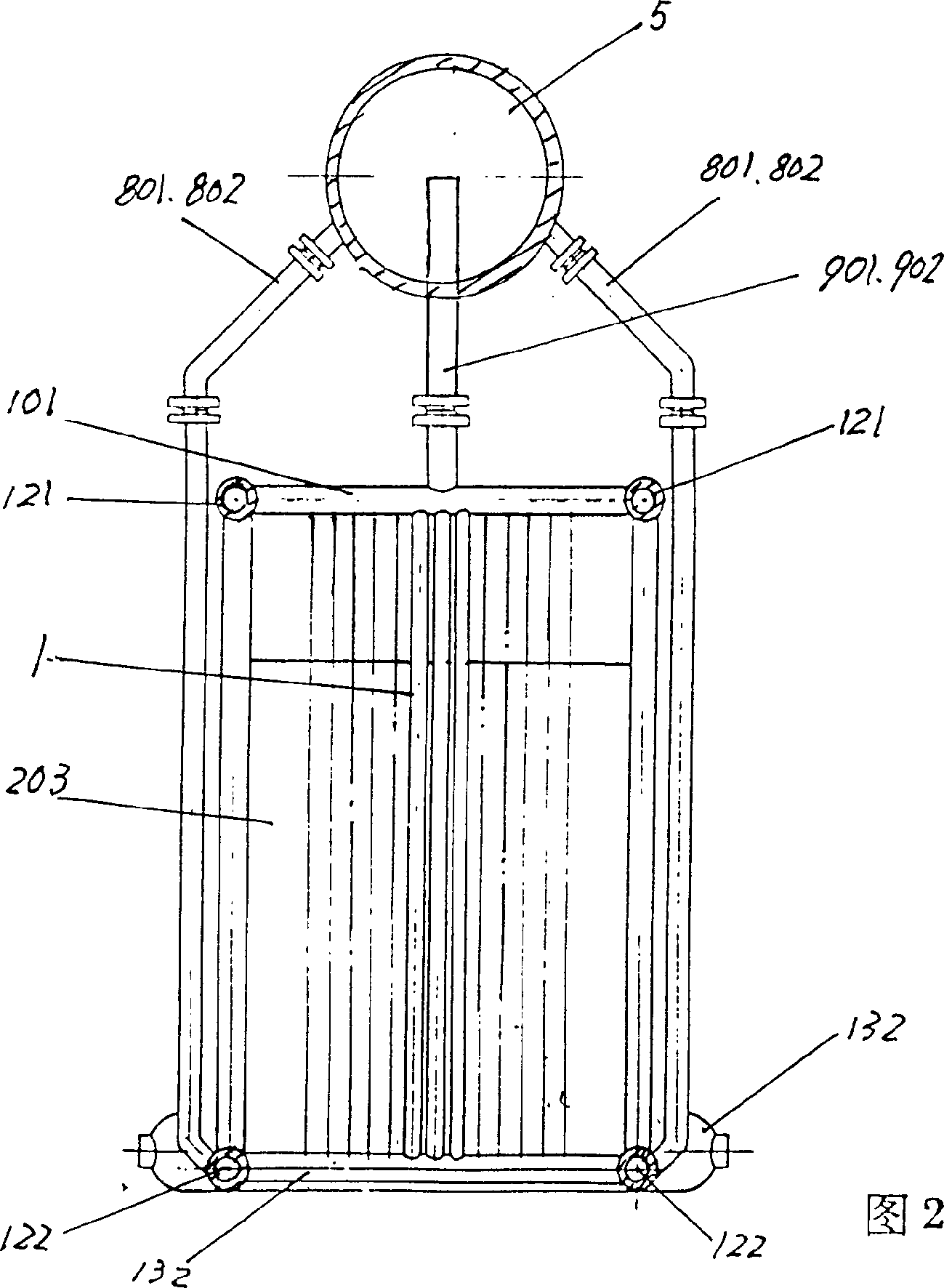

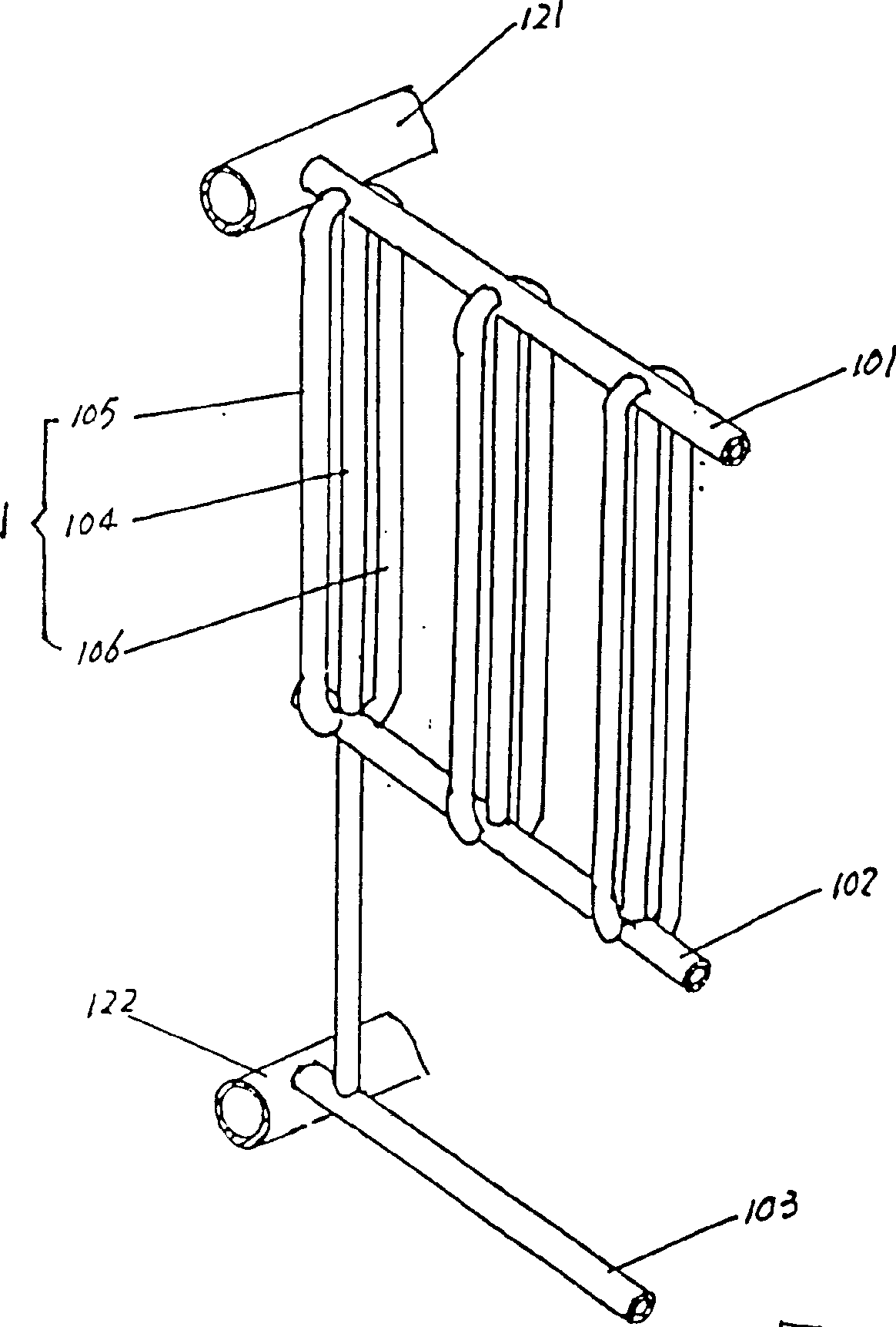

[0017] Figure number:

[0018] 1. Multi-tube heat generator (the left, right and middle of the pot are equipped)

[0019] 101. Upper horizontal tube 102. Middle horizontal tube

[0020] 103. Lower horizontal pipe 104. Middle vertical pipe

[0021] 105. Left standpipe 106. Right standpipe

[0022] 201, 202, 203, 204. Return air partition

[0023] 301, 302, 303, 304, 305. Fire area 401, 402, 403. Fire door

[0024] 5. Conjoined water tank

[0025] 6. Safety exhaust device

[0026] 7. Level gauge

[0027] 801, 802. Water tank cold water drop pipe (left and right one row each)

[0028] 901, 902. Heat generator hot water rising pipes (one row on the left and right)

[0029] 10. Water tank sewage pipe

[0030] 11. Pot exhaust duct

[0031] 121. The header on the pot (one row on the left and right) 122. The header on the pot (one row on the left and right)

[0032] 131. Horizontal header on the pot (one on the left and one on the right) 132. Horizontal header on the pot (one on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com