Rapid gel composition, product thereof and application

A gel composition, rapid technology, applied in the fields of application, food science, food ingredients, etc., can solve the problems of long gelation time, high temperature, long processing time, etc., and achieve simple process, excellent texture, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Example 1: Preparation of base formulation

[0084] As shown in the basic formula in Table 1, weigh the carrageenan, polypeptide and citric acid in the formula and mix them evenly, then use 25 mL of warm water to prepare, stir evenly, and place at room temperature to gel. A timer is used to calculate the time from the completion of the preparation to the formation of a gel (gel formed from a liquid substance, as long as the colloid can peel off the wall of the container), that is, the gel time.

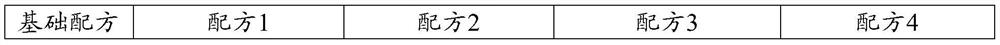

[0085] Table 1: Base Recipe

[0086]

[0087]

[0088] It can be seen from Table 1 that the gel can not be formed by using carrageenan alone; adding collagen or citric acid alone, it is difficult to obtain a fast gel composition with a short gel time when compounded with carrageenan. When the system is combined with carrageenan, collagen and citric acid, collagen and citric acid have a synergistic effect, and the gel time is significantly shortened.

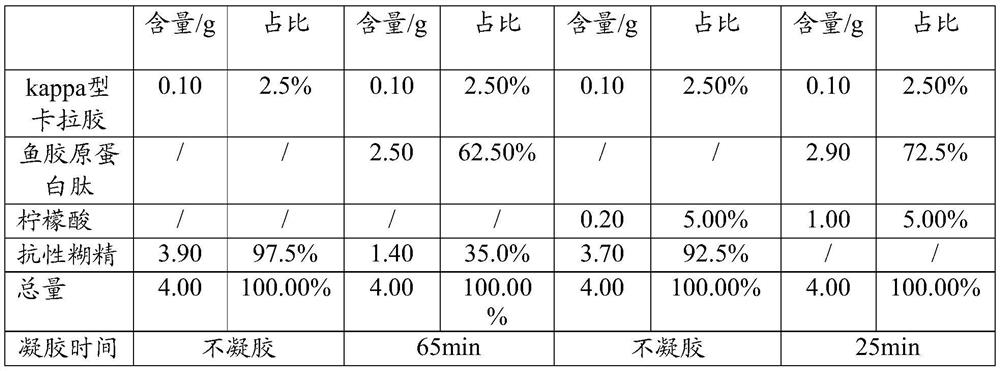

[0089] Table 2: Ba...

Embodiment 2

[0097] Example 2: Effects of different peptides on carrageenan gel time.

[0098] This example further investigates the effect of different polypeptides on the gel time, and the gel time is investigated by adding food functional ingredients and thickeners (eg xanthan gum) to the basic formula of Example 1.

[0099] As described in Table 4 and Table 5, the formula amounts of carrageenan, xanthan gum and polypeptide (as shown in Table 4), citric acid and water-soluble dietary fiber resistant dextrin (Shanghai Tongyuan Health Technology Co., Ltd. Company) to mix evenly, then use 25mL of warm water to mix, stir well and then place at room temperature to gel. A timer is used to calculate the time from the completion of the preparation to the formation of the gel, the gel time.

[0100] Table 4: Composition formulation of the gel of Example 2

[0101]

[0102] Table 5: Various polypeptide species used in Example 2 and corresponding gel times

[0103]

[0104] In the above e...

Embodiment 3

[0105] Example 3: Effects of Different Collagen Content on Gel Time

[0106] This example further examines the effect of different concentrations of collagen peptide 1000 on gel time when collagen peptide 1000 is used. As described in Table 6, weigh the formula amounts of carrageenan, xanthan gum and collagen peptide 1000 (additional amounts are shown in Table 6), citric acid and water-soluble dietary fiber resistant dextrin and mix them evenly. Use warm boiled water to prepare, stir evenly and then place at room temperature to gel. A timer is used to calculate the time from the completion of the preparation to the formation of the gel, the gel time.

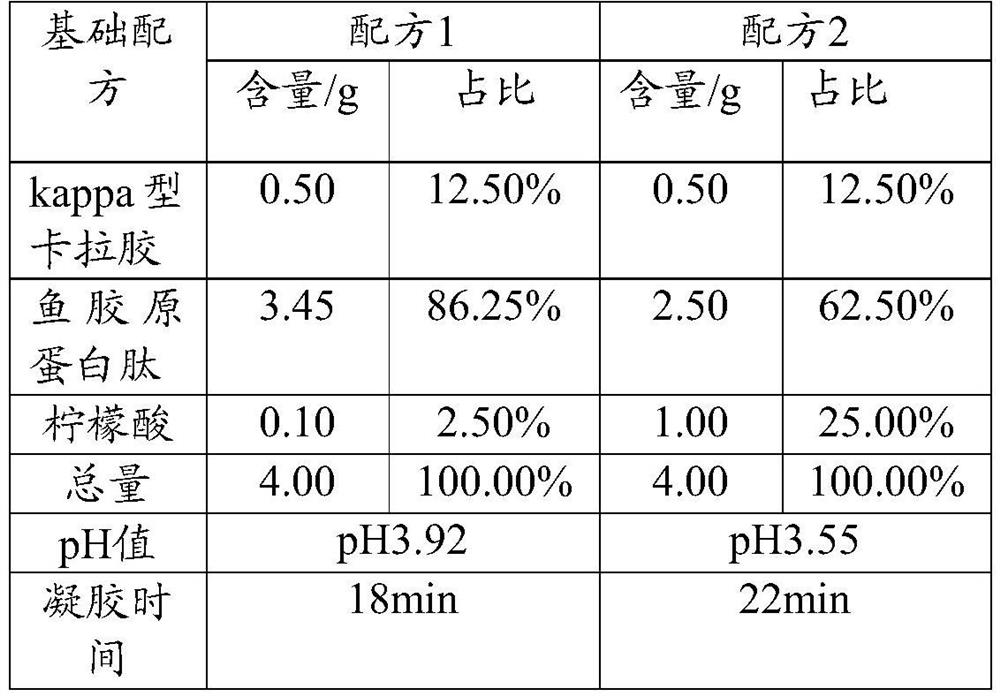

[0107] Table 6: Different Fast Gel Composition Formulations and Corresponding Gel Times

[0108]

[0109]

[0110] It can be seen from the above experiments that under the condition that carrageenan, water-soluble dietary fiber, xanthan gum and citric acid remain unchanged, within a certain addition range (2.27%-26%), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com