High-purity gallium particle production technical method

A production process and high-purity technology, applied in the field of high-purity gallium, can solve the problems of high cost and difficulty of high-purity gallium particles, and achieve the effects of simple preparation method, inhibiting oxidation reaction, and improving the purity of gallium particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for producing high-purity gallium grains, comprising the steps of:

[0025] S1. Add concentrated hydrochloric acid to the deionized water exchange water to obtain a coolant; melt the high-purity gallium raw material into a liquid state, and put it into a drip bottle; preferably, the resistivity of the deionized water is greater than 16 megohms, and the concentrated hydrochloric acid is exchanged with deionized The volume ratio of water is 1:200; preferably, the melting temperature of the high-purity gallium raw material is 45-55°C, most preferably, the melting temperature of the high-purity gallium raw material is 50°C;

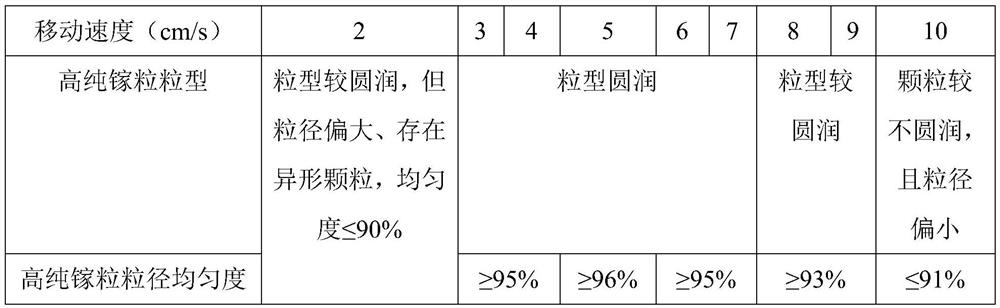

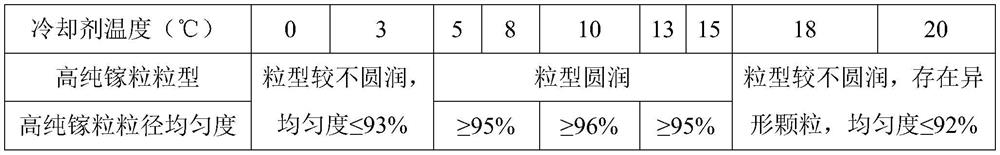

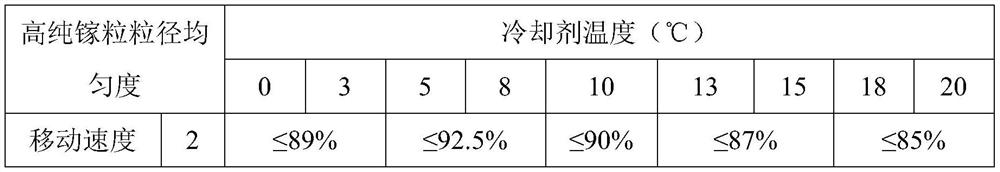

[0026] S2. Place the opening of the dripping bottle in the coolant, the temperature of the coolant is 5-15°C, start dripping, move the dripping bottle horizontally at a speed of 3-9cm / s during the dripping process, the liquid is high-purity The gallium raw material is solidified into high-purity gallium particles after being dropped into the c...

Embodiment 2

[0047] On the basis of Embodiment 1, this embodiment further includes: the height of the liquid high-purity gallium raw material dropping to the bottom of the coolant after being dropped into the coolant is greater than or equal to 25 cm. After researching the production process provided in this example, the inventor found that when the liquid high-purity gallium raw material drops into the coolant during the dropping process and the height of the drop to the bottom of the coolant is too low, the obtained high-purity gallium grains are prone to abnormal shapes. Particles reduce the uniformity of high-purity gallium particles, see Table 4 below for details:

[0048] Table 4 Effect of drop height on high-purity gallium particles

[0049]

[0050] Note: The uniformity in the above table refers to the content of gallium grains with a particle size of ±0.5mm that accounts for the most in the obtained high-purity gallium grains.

[0051] It can be seen from the above table that ...

Embodiment 3

[0053] On the basis of Example 1, this embodiment further includes: the opening diameter of the drip opening of the drip bottle is 0.6-2.6 mm, and high-purity gallium particles with a particle size of 1 mm-10 mm are prepared. Preferably, when the opening aperture of the dripping bottle is 0.8 ± 0.2 mm, high-purity gallium particles with a particle size of 1 to 2 mm are prepared; when the opening aperture of the dripping bottle is 1.2 ± 0.2 mm When the particle size is 0.2 mm, high-purity gallium particles with a particle size of 2 mm to 3 mm are prepared; when the opening diameter of the drop opening of the dripping bottle is 1.6 ± 0.2 mm, high-purity gallium particles with a particle size of 3 mm to 5 mm are prepared. grains; when the opening diameter of the dripping mouth of the dripping bottle is 2±0.2mm, high-purity gallium grains with a particle size of 5mm to 7mm are prepared; when the opening diameter of the dripping opening of the dripping bottle is 2.4±0.2mm mm, high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com