Novel coronavirus vero cell inactivated vaccine virus solution and production method thereof

A coronavirus and production method technology, applied in the field of novel coronavirus Vero cell inactivated vaccine virus liquid, can solve the problems of no novel coronavirus liquid technical report, no effective preventive vaccine for novel coronavirus, etc., and achieve batch-to-batch differences Highly controllable, uniform quality, high cell seeding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: the culture of Vero cell

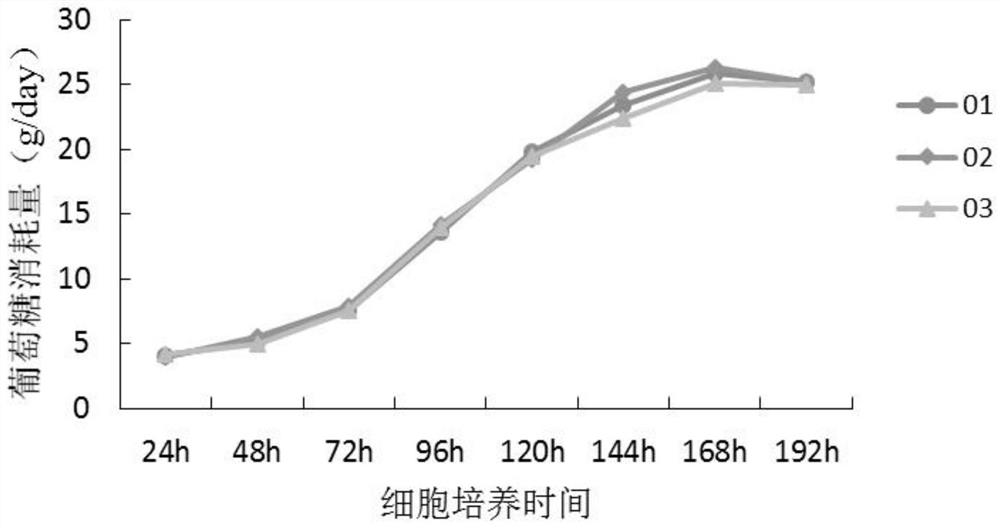

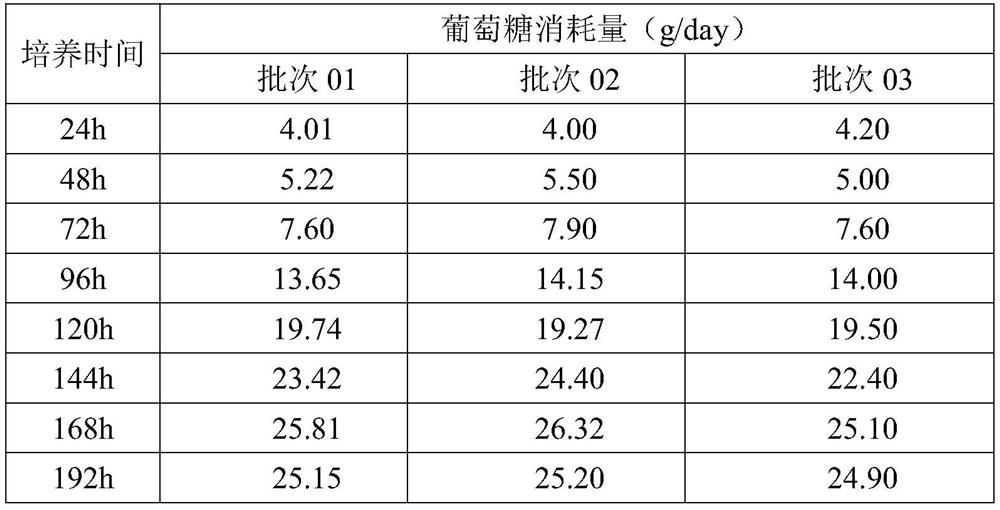

[0050] Inject a certain volume of cell growth solution into the pre-sterilized 10L basket reactor equipped with a three-dimensional book-type carrier (carrier model: TQ1000w, no-cleaning; provider: Shanghai Chukun, 30-50g / L) (M199 medium containing 8% newborn bovine serum), then inject Vero cells into the tank body, and the cell seeding density is not lower than 1×10 6 cells / ml; then supplement the liquid level with cell growth liquid to the highest scale line of the liquid level and set the parameters of the reactor: the culture speed is 50-150rpm; the dissolved oxygen is not less than 40%; the gas flow rate is 4Gas: 0.1 ; The pH value is controlled between 7.2 and 7.4; the temperature is 36.5±1°C. During the cell culture process, glucose monitoring was used to determine whether the cells grew into a monolayer, and Table 1 was the glucose consumption of Vero cells under different culture time conditions; figure 1 Shows glucose...

Embodiment 2

[0054] Embodiment 2: the cultivation of novel coronavirus

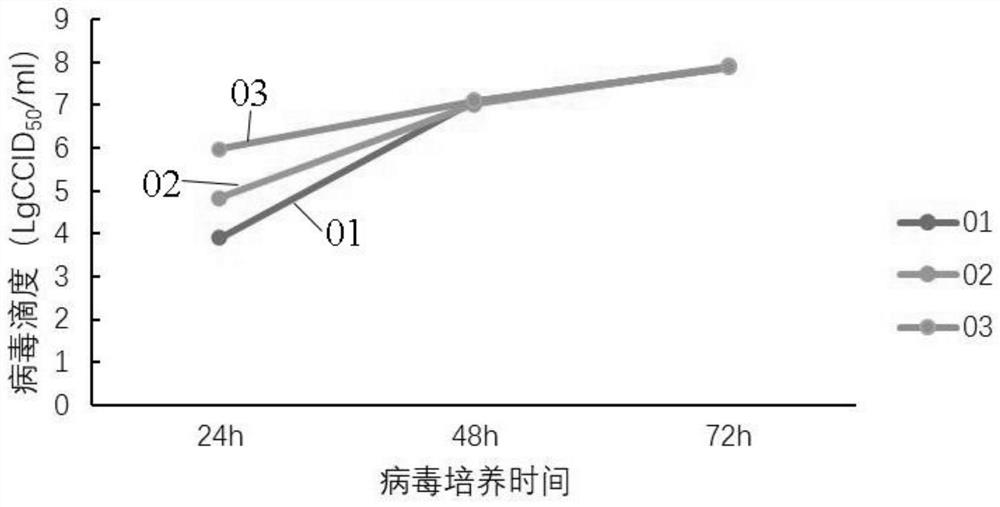

[0055] When the Vero cells were cultured for 6-8 days, the new coronavirus SARS-CoV-2 was inoculated, and the MOI of the three batches of virus inoculation were 0.005, 0.01, and 0.3, respectively. Before virus inoculation, the cell growth liquid in the reactor was discarded, and the cell maintenance liquid (M199 medium without serum) was added to wash and remove bovine serum. Melt the virus seeds in a water bath in the isolator, add the virus seeds into the cell maintenance solution (M199 medium without serum), shake and mix well, then pump the virus-containing cell maintenance solution into the tank. After inoculation, aeration and agitation culture is carried out at 36±1°C, the culture speed is 50-150 rpm, the dissolved oxygen is not less than 40%, and the pH value is controlled between 7.2-7.6 during the culture. Table 2 shows the virus titers of the new coronavirus under different culture time conditions; figur...

Embodiment 3

[0059] Embodiment 3: Harvesting of virus liquid

[0060] From the beginning of virus inoculation, the virus liquid was harvested within 48-96 hours of culture. Turn off the temperature, pH, and DO functions of the basket reactor, open the harvesting pipeline, and use the positive pressure in the tank to collect the virus liquid. The virus titers of the specific virus harvest liquid are shown in Table 3.

[0061] table 3:

[0062] Batches of virus fluid Virus titer (LgCCID 50 / ml)

[0063] From the above experimental results in Table 3, it can be seen that the present invention adopts a basket reactor to cultivate novel coronavirus, with high cell inoculation density, high virus titer, highly controllable batch-to-batch variation, and uniform quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com