Paper-based aluminum air battery with liquid alloy modified anode and preparation method

A liquid alloy, air battery technology, applied in the electrode of primary battery, fuel cell type half cell and primary battery type half cell, etc., can solve the research of aluminum anode surface modification of aluminum air battery, neutral electrolyte discharge Insufficient power and insufficient utilization of aluminum anodes can meet the needs of low-power market applications, achieve miniaturization and light weight, and long discharge time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

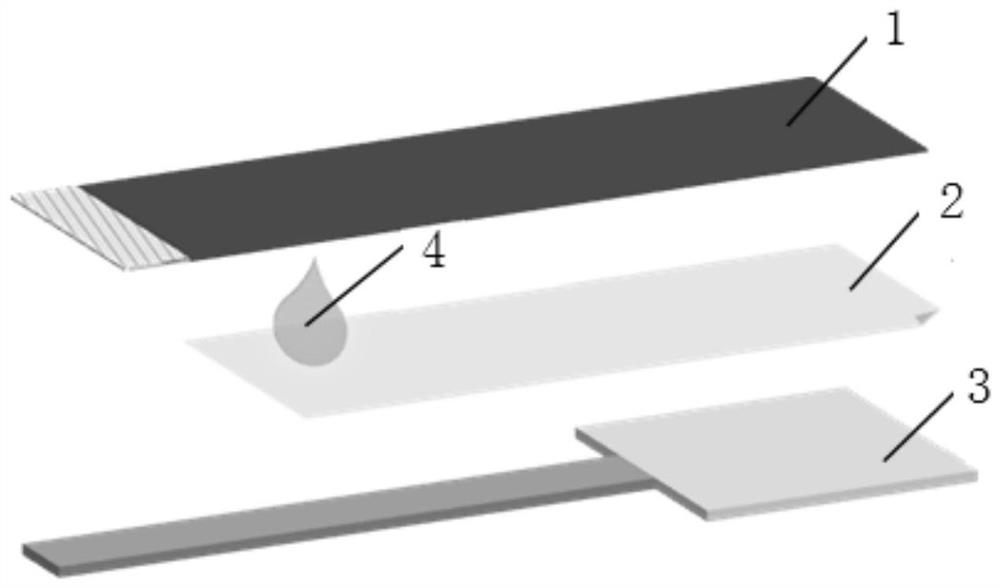

[0050] A method for preparing a paper-based aluminum-air battery with a liquid alloy modified anode, comprising the following steps:

[0051] S1. After choosing two or more of Ga, In, Sn, Zn, and Bi according to the ratio, heat and keep it in an inert gas atmosphere at a temperature 100°C higher than the melting point of the selected element, and it is worth liquid alloy ;

[0052] S2. Alloying the liquid alloy prepared in step S1 at room temperature for 10-24h;

[0053] S3. Mix liquid alloy, surfactant, and solvent according to the ratio of 0.01-10g: 0.01-20g: 10-100ml, and ultrasonically stir for 20-40min to prepare liquid alloy particles;

[0054] S4. Loading the liquid alloy particles on the surface of the aluminum anode;

[0055] S5. The aluminum anode loaded with liquid alloy particles, the paper base, and the air electrode are sequentially superimposed to obtain a paper-based aluminum-air battery, and the low-power discharge can be realized by adding electrolyte to th...

Embodiment 1

[0057] The air electrode is a commercially available air electrode; the paper base is filter paper, and the filter paper is folded to a thickness of 1mm; the aluminum anode is made of a purity of 99%, a thickness of 0.2mm, and an area of 1cm 2 aluminum foil; the liquid alloy is 74.5% Ga25.5% In binary alloy, the loading capacity is 50ug / cm 2 ; The electrolyte is 2M NaCl solution.

[0058]1. Preparation of liquid alloy: Weigh Ga and In according to the mass fraction of 74.5% Ga and 25.5% In respectively, put the weighed metal in a high-temperature furnace under nitrogen protection, sinter at 250°C, and sinter at 250°C Heat and keep warm for 1.5 hours. Cool to room temperature after heat preservation, and alloy the obtained liquid alloy at room temperature for 20 hours.

[0059] 2. Preparation of liquid alloy particles: Mix the alloyed liquid alloy with sodium dodecyl sulfate (SDS) and N-methylpyrrolidone (NMP) at a ratio of 2g:1g:20ml, and stir ultrasonically for 30min to o...

Embodiment 2

[0065] The air electrode is a commercially available air electrode; the paper base is filter paper, and the filter paper is folded to a thickness of 0.5mm; the aluminum anode is 99% pure and 0.5mm thick, with an area of 1cm 2 aluminum foil; the liquid alloy is 66%Ga13.5%In20.5%Sn ternary alloy, the loading capacity is 10ug / cm 2 ; The electrolyte is 2M NaCl solution.

[0066] 1. Preparation of liquid alloy: Weigh Ga, In and Sn respectively according to the mass fraction of 66% Ga, 13.5% In, and 20.5% Sn, and place the weighed metal in a high-temperature furnace under nitrogen protection at 250°C Sinter, and heat and hold at 250°C for 1.5 hours. Cool to room temperature after heat preservation, and alloy the obtained liquid alloy at room temperature for 24 hours.

[0067] 2. Preparation of liquid alloy particles: Mix the alloyed liquid alloy with sodium dodecyl sulfate (SDS) and N-methylpyrrolidone (NMP) at a ratio of 2g:1g:20ml, and stir ultrasonically for 30min to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com