A novel printable flexible paper-based aluminum-air battery

An aluminum-air battery, paper-based technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. cost, the effect of realizing large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

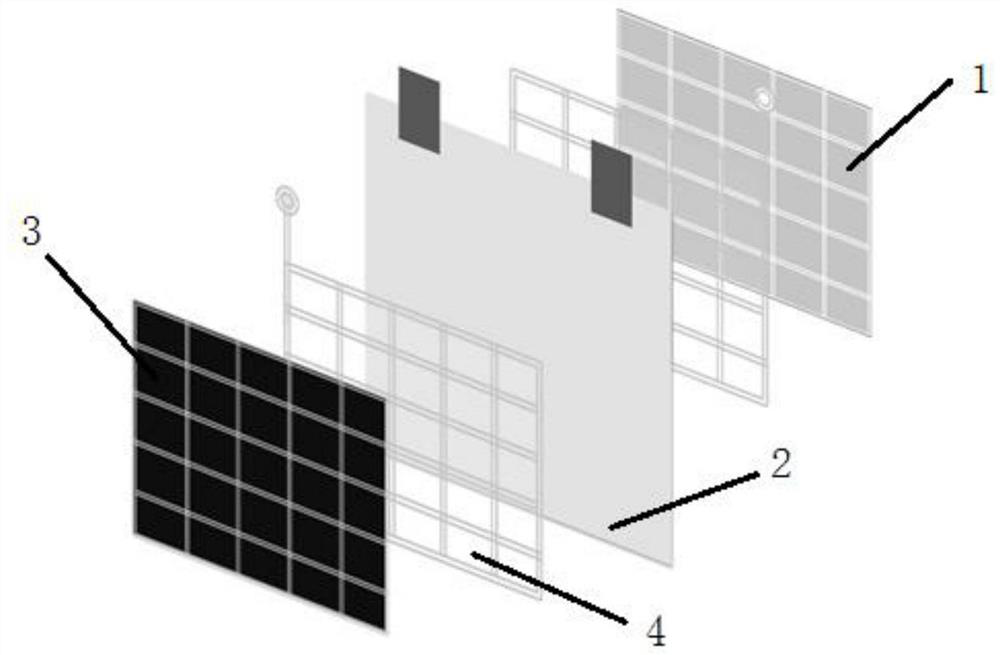

Image

Examples

preparation example Construction

[0044] Further, the preparation method of the aluminum ink anode comprises the following steps:

[0045] 1. After selecting two or more of Ga, In, Sn, Zn, and Bi according to the ratio, heat and hold for 1-2 hours in an inert gas atmosphere at a temperature 100°C higher than the melting point of the selected element to obtain a liquid alloy Finally, alloy the liquid alloy at room temperature for 10-24h;

[0046] 2. Mix liquid alloy, surfactant, and solvent according to 0.01-10g: 0.01-20g: 10-100ml, and ultrasonically stir for 20-40min to prepare liquid alloy particles;

[0047] 3. Control the mass ratio of aluminum powder and liquid alloy particles between 10:1 and 50:1, and the mass ratio of aluminum powder and carboxymethyl cellulose between 30:1 and 150:1; and carboxymethyl cellulose are mixed and added to 30-70% ethanol solution, and ultrasonicated for 10-30 minutes to ensure uniform mixing to prepare an aluminum ink anode.

[0048] Further, the carbon ink cathode is mad...

Embodiment 1

[0052]The aluminum ink anode is prepared by commercially available 200 mesh aluminum powder, mass fraction 74.5%: Ga25.5% In liquid alloy, carboxymethyl cellulose (CMC), 50% ethanol aqueous solution; the carbon ink air cathode is prepared by 50% MnO 2 -CNTs, Nafion binder, and 50% ethanol aqueous solution are prepared; the electrolyte is 2M NaCl.

[0053] 1. Preparation of aluminum ink anode:

[0054] (1) Heating a gallium-indium alloy with a mass fraction of 74.5% Ga: 25.5% In in a nitrogen atmosphere to 300°C and holding it for 2 hours to obtain a liquid alloy, and alloying the liquid alloy for 20 hours;

[0055] (2) Mix the prepared gallium indium liquid alloy, surfactant sodium lauryl sulfate, and solvent N-methylpyrrolidone according to 1g: 1g: 20ml, and ultrasonically stir for 30 minutes to obtain liquid alloy particles;

[0056] (3) Aluminum powder, liquid alloy particles, and carboxymethyl cellulose were mixed at a mass ratio of 40:2:1, then added to 50% ethanol aqueo...

Embodiment 2

[0066] Aluminum ink anode is prepared by commercially available 200 mesh aluminum powder, mass fraction 66% Ga: 13.5% In: 20.5% Sn liquid alloy, carboxymethyl cellulose (CMC), 30% ethanol aqueous solution; carbon ink air cathode is prepared by 50% MnO 2 -CNTs, Nafion binder, and 30% ethanol aqueous solution are prepared; the electrolyte is 2M NaCl.

[0067] 3. Preparation of aluminum ink anode:

[0068] (4) Heating a gallium indium tin alloy with a mass fraction of 66% Ga: 13.5% In: 20.5% Sn to 250°C in a nitrogen atmosphere and holding it for 2 hours to obtain a liquid alloy, and alloying the liquid alloy for 20 hours;

[0069] (5) Mix the prepared gallium indium liquid alloy, the surfactant sodium lauryl sulfate, and the solvent N-methylpyrrolidone according to 1g: 2g: 10ml, and ultrasonically stir for 30 minutes to obtain liquid alloy particles;

[0070] (6) Aluminum powder, liquid alloy particles and carboxymethyl cellulose were mixed at a mass ratio of 30:3:1, then added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com