5G communication filter dielectric ceramic piece semi-finished product and forming method thereof

A technology of dielectric ceramics and molding methods, which is applied in the direction of ceramic molding machines, waveguide devices, and auxiliary molding equipment. It can solve problems such as uneven density of compacted blanks, products that affect product yield, and difficult control of dimensions, so as to improve injection molding. Forming defects, reduce the difficulty of production, reduce the effect of multiple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

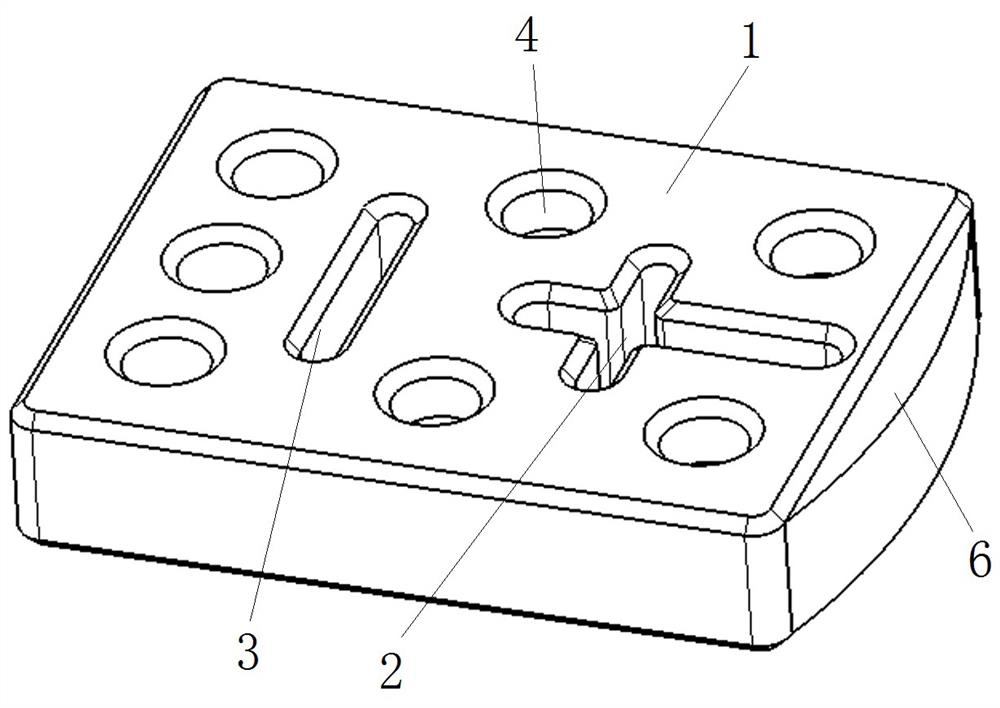

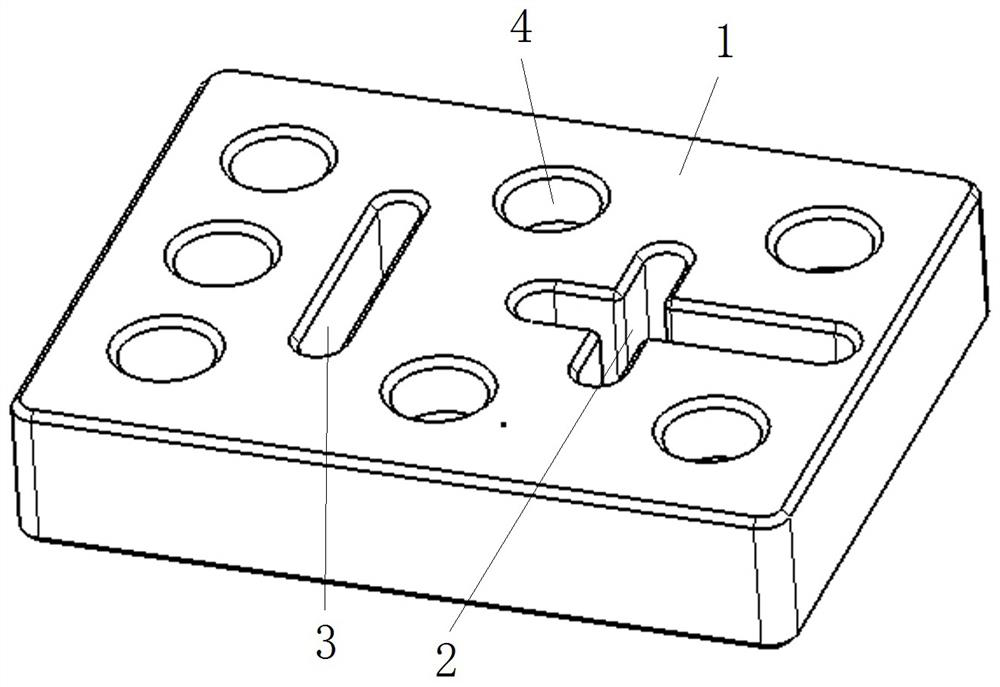

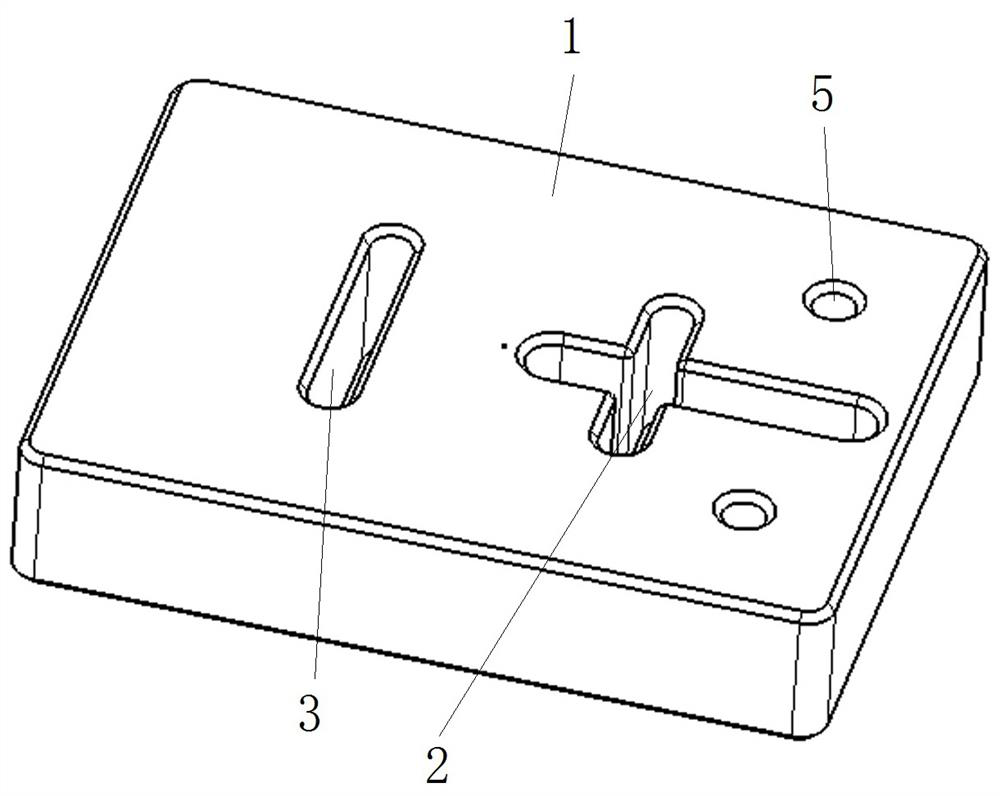

[0028] Please refer to Figure 1-Figure 2 , a preferred embodiment of the present invention is.

[0029] The dielectric ceramic part of the 5G communication filter made by the semi-finished product of the dielectric ceramic part of the 5G communication filter in this embodiment can be fixed in the housing of the 5G communication filter for filtering microwave communication signals. Specifically, a semi-finished product of a 5G communication filter dielectric ceramic part, including a main body 1, the main body 1 is provided with a cross-shaped through hole 22 and a straight through hole 3, the cross-shaped through hole 22 is located on the edge of the main body 1, and the front of the main body 1 A first blind hole 4 is provided, a second blind hole 5 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com