Full-automatic assembling machine for wiring terminal

A terminal, fully automatic technology, applied in the assembly/disassembly of contacts, etc., can solve the problems of increased workload, inability to meet the needs of multiple assembly steps of the terminal, and short parts, and achieve the effect of improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

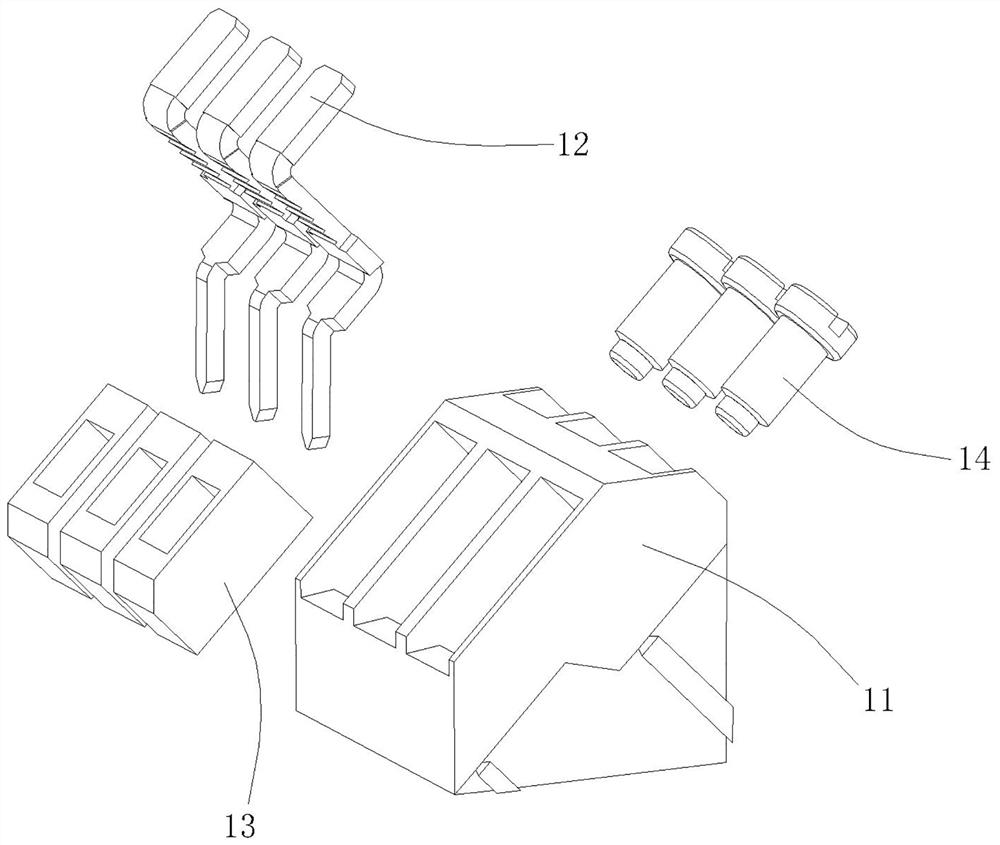

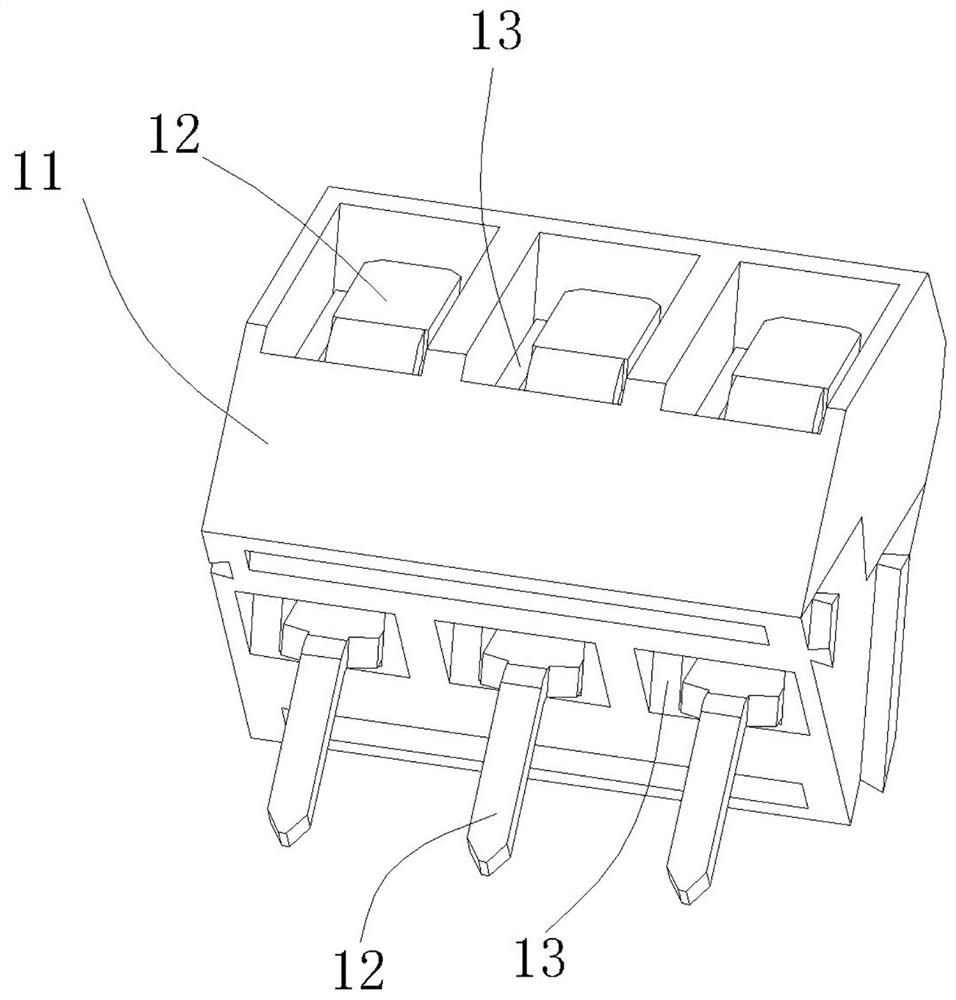

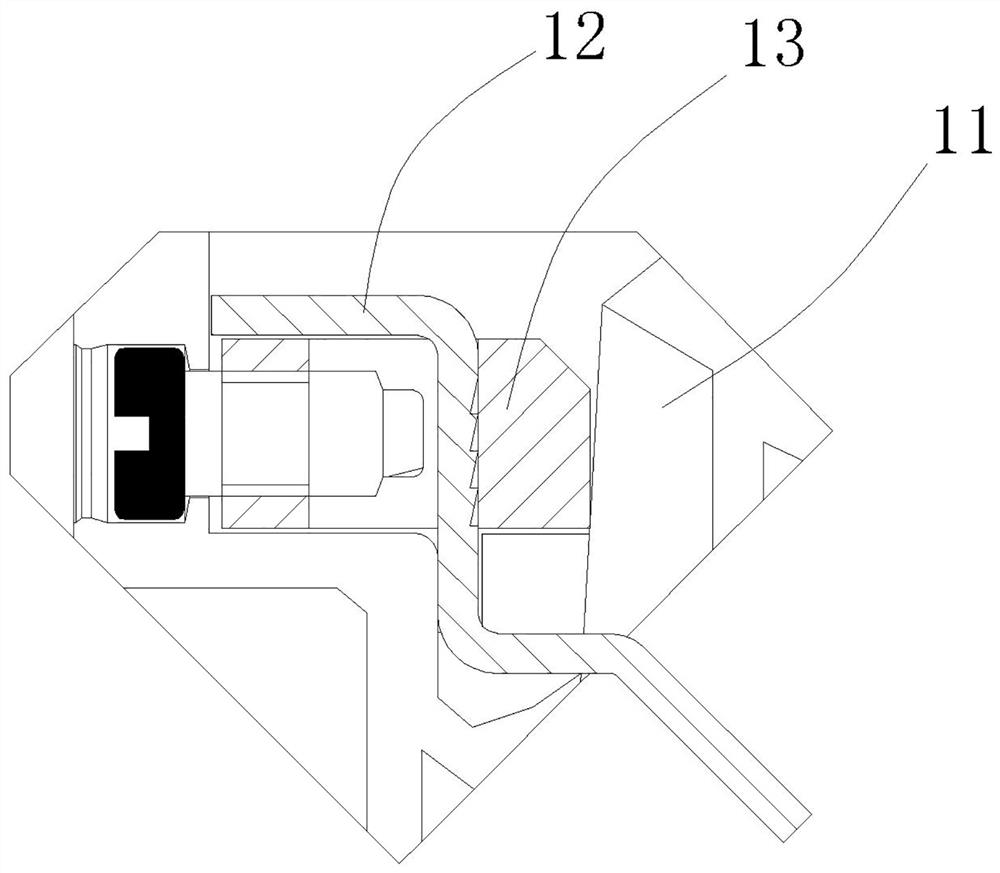

[0045] refer to Figure 1~4 , this figure shows the overall product structure diagram of the terminal to be assembled, which mainly includes the plastic case 11, the soldering leg 12, the foot seat 13 and the nail 14, the welding leg 12 is put into the foot seat 13 first when assembling, and then Flip the foot 13 at a certain angle to complete the assembly of the welding foot 12 and the foot 13, then put the assembly 15 of the welding foot 12 and the foot 13 into the plastic case 11 horizontally, and then push the assembly 12 obliquely upward to realize the assembly with the foot 13. For the assembly of the plastic case 11, nails 14 are driven into the foot base 13 at last to press the welding legs 12 so as to complete the overall assembly.

[0046] refer to Figure 5 ~ Figure 21 , a fully automatic assembly machine for terminal blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com