High-frequency signal output circuit

A technology for outputting circuits and high-frequency signals. It is applied in the direction of electric pulse generator circuits and active components to generate pulses. It can solve the problems that various characteristic parameters of waveforms and waveform distortion cannot be guaranteed, and achieve excellent square wave signal output and performance. Reliable, adaptable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

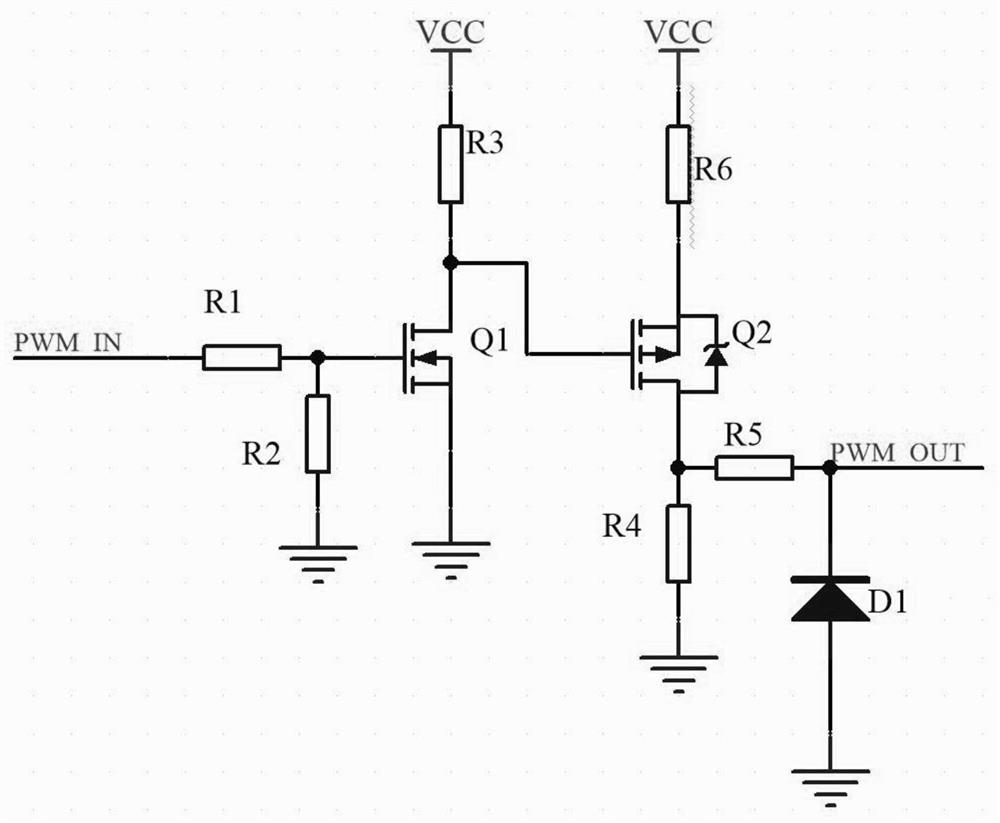

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0019] The high-frequency signal output circuit of this embodiment is mainly used in the output signal processing scene of the automobile controller, which includes the working power supply VCC part and the fast operation signal processing circuit, wherein the working power supply VCC can adopt the direct current of the vehicle controller power supply circuit itself The output voltage of the voltage stabilizing chip can also adopt the stabilizing power supply voltage outside the controller, and the range of the working power supply VCC can be +5V~+12V.

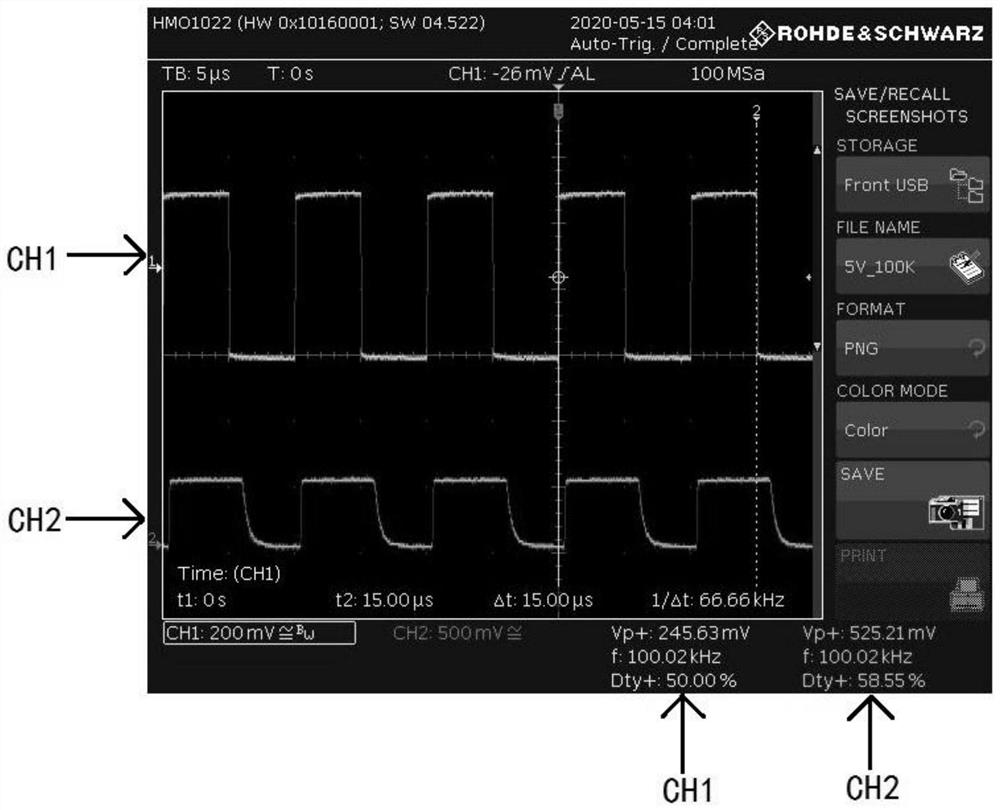

[0020] Such as figure 1 As shown, the input PWM_IN signal is a +5V PWM square wave signal sent by the main chip of the vehicle controller. This signal is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com