Preparation method of composite enzymolysis-fermentation coupled fermented pine pollen extract

A compound enzymatic hydrolysis and pine pollen technology, applied in the direction of bacteria used in food preparation, food science, application, etc., can solve the problems of pine pollen easy to oxidize storage time, inedible pine pollen, difficulty in digesting pine pollen, etc., and achieve improvement Antioxidant effect, contribution to fermentation efficiency, and effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

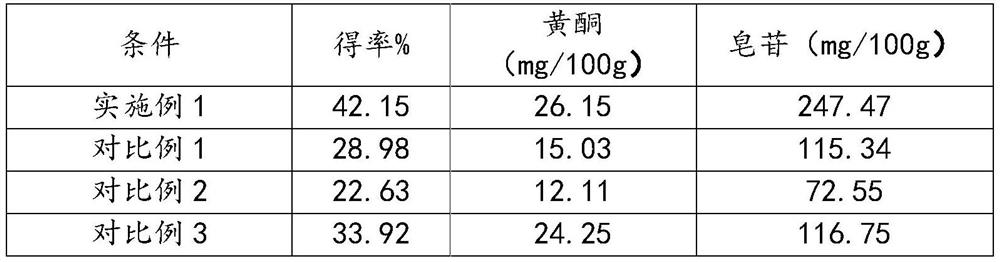

Embodiment 1

[0053] (1) 9000rpm 9000rpm ultrafine grinding of pine pollen for 15 minutes to obtain broken wall pine pollen, and the measured wall breaking rate is 85%;

[0054] The broken wall pine pollen is dropped into fermenter tank, add water in tank by 9 times of dropping into broken wall pine pollen quality, open and stir; Drop into the acid cellulase of 0.1wt% and 0.1wt% by broken wall pine pollen quality meter in fermenter tank % acid pectinase, adjust the pH to 5.0 with hydrochloric acid or sodium hydroxide; heat up to 50°C and keep it warm, enzymolysis treatment for 2h;

[0055] (2) After the enzymolysis is completed, add glucose to the tank in an amount of 0.1 times the mass of broken pine pollen; add peptone in an amount of 0.05 times the mass of broken pine pollen; add whey protein powder in an amount of broken pine pollen 0.025 times the mass; adjust the pH to 7.5 with sodium hydroxide; sterilize at 85°C for 30 minutes;

[0056] (3) After the sterilization, the fermenter was c...

Embodiment 2

[0061] (1) 9000rpm 9000rpm ultrafine grinding of pine pollen for 15 minutes to obtain broken wall pine pollen, and the measured wall breaking rate is 85%;

[0062] The broken-walled pine pollen is dropped into fermenter, and water is added to the tank by 12 times of the quality of broken-walled pine pollen, and stirring is started; in the fermenter, 0.15wt% acid cellulase and 0.15wt% acid cellulase are dropped into the broken-walled pine pollen mass. % acid pectinase, adjust the pH to 5.0 with hydrochloric acid or sodium hydroxide; heat up to 55°C and keep it warm, enzymolysis treatment for 2h;

[0063] (2) After the enzymolysis is completed, add glucose to the tank in an amount of 0.08 times the mass of broken pine pollen; add peptone, and use an amount of 0.04 times the mass of broken pine pollen; add whey protein powder, and use an amount of broken pine pollen 0.015 times the mass; adjust the pH to 7.5 with sodium hydroxide; sterilize at 85°C for 30 minutes;

[0064] (3) A...

Embodiment 3

[0069] (1) 9000rpm 9000rpm ultrafine grinding of pine pollen for 15 minutes to obtain broken wall pine pollen, and the measured wall breaking rate is 85%;

[0070] The broken wall pine pollen is dropped into fermenter tank, add water in the tank by 7 times of dropping into broken wall pine pollen quality, open and stir; Drop into the acid cellulase of 0.08wt% and 0.08wt% by broken wall pine pollen mass meter in fermenter tank % acid pectinase, adjust the pH to 5.0 with hydrochloric acid or sodium hydroxide; heat up to 50°C and keep it warm, enzymolysis treatment for 2h;

[0071] (2) After the enzymolysis is completed, add glucose to the tank in an amount of 0.1 times the mass of broken pine pollen; add peptone in an amount of 0.05 times the mass of broken pine pollen; add whey protein powder in an amount of broken pine pollen 0.025 times the mass; adjust the pH to 7.5 with sodium hydroxide; sterilize at 85°C for 30 minutes;

[0072] (3) After the sterilization is finished, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com