Material moisture content control system, drum-type cut tobacco dryer and material moisture content control method

A control system and moisture content technology, applied in the field of tobacco machinery, can solve the problems of poor control effect of material moisture content and difficult control of material dehydration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

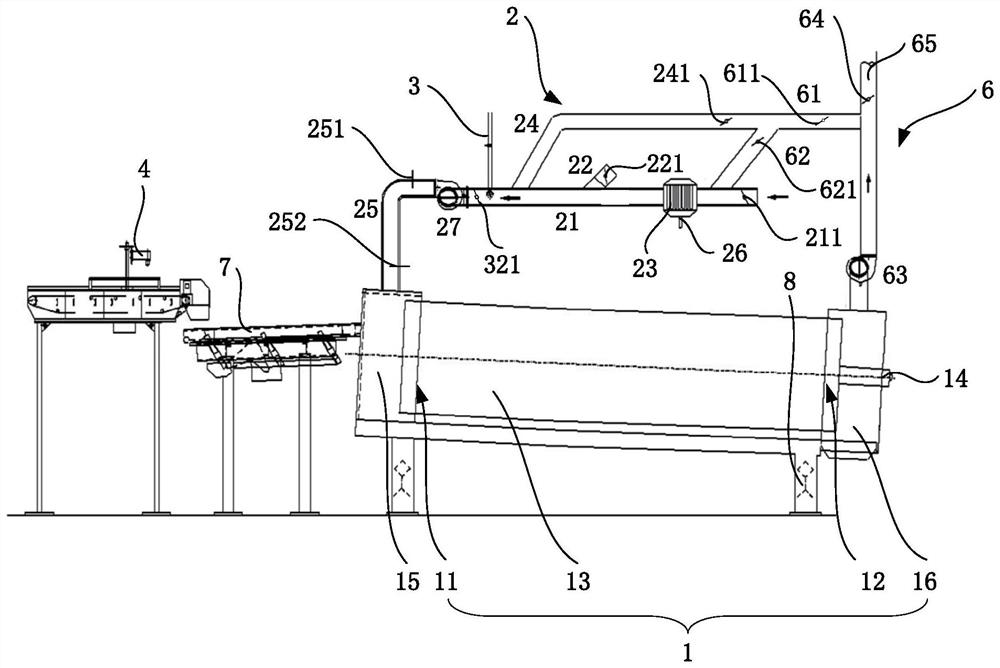

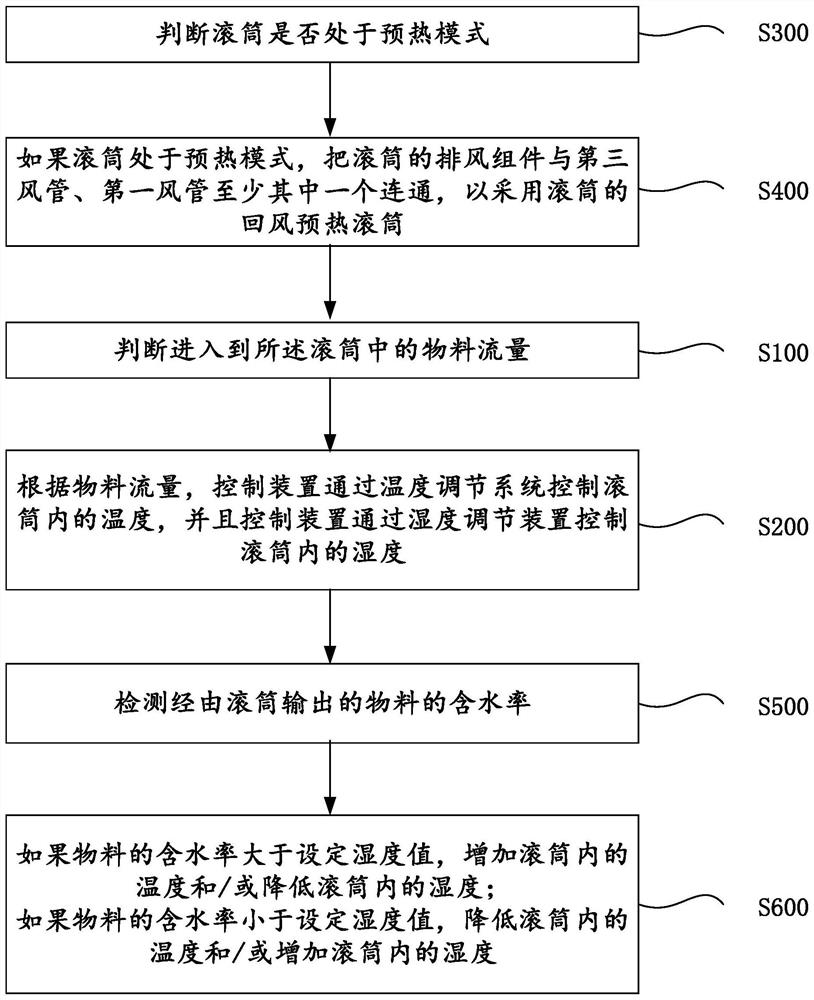

[0054] Combine below Figure 1 ~ Figure 3 The technical solution provided by the present invention is described in more detail.

[0055] see Figure 1 to Figure 2 Some embodiments of the present invention provide a material moisture content control system, including a drum 1, a temperature adjustment device 2, a humidity adjustment device 3, a feed flow detection device 4 and a control device (not shown).

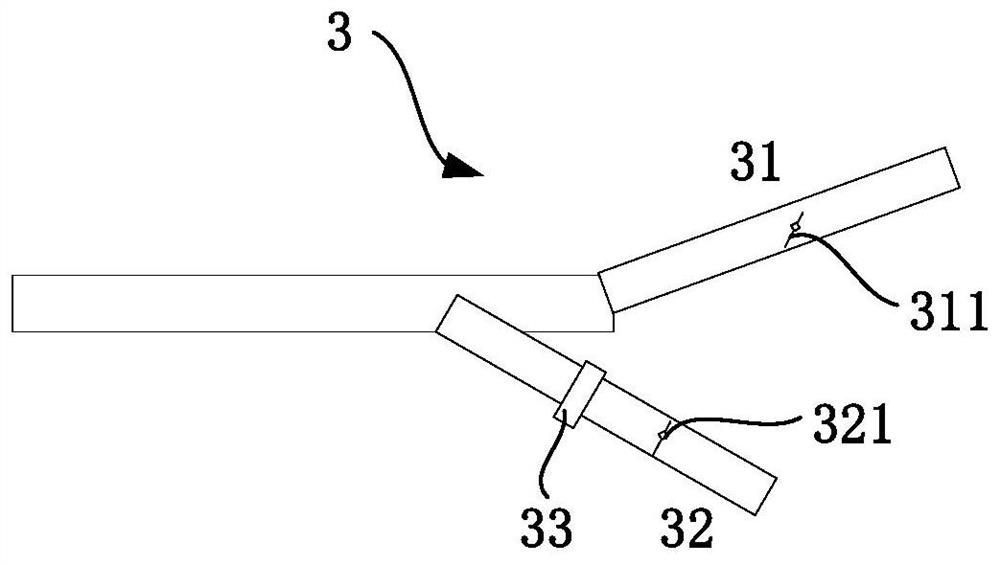

[0056]The drum 1 has a feed end 11 , a discharge end 12 and an inner cavity 13 for accommodating materials; both the feed end 11 and the discharge end 12 communicate with the inner cavity 13 . The drum 1 is supported by a frame 8 . The temperature regulating device 2 communicates with the feed end 11 and / or the inner chamber 13 of the drum 1 to change the temperature inside the drum 1 , specifically, the temperature inside the drum 1 can be changed by changing the temperature of the process air entering the drum 1 . Humidity adjustment device 3 communicates with the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com