Jasmine cigarette and production method

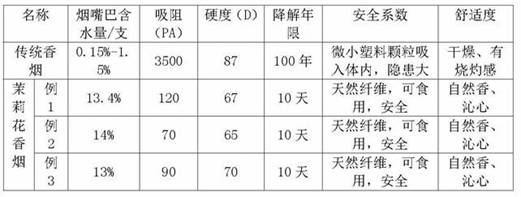

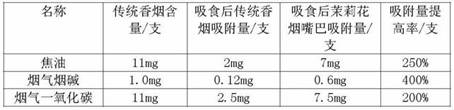

A production method and technology for jasmine flowers, which are applied in the field of jasmine cigarettes and production, can solve the problems of poor adsorption capacity, unnatural fragrance, and large hidden dangers, and achieve the effects of strong adsorption capacity, high water content and symptom relief.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of jasmine cigarette, is made of following raw material: jasmine, konjac whole powder, water and coagulant; Jasmine is the powdery particle after processing; Coagulant is sodium carbonate;

[0045] The parts by weight of each component are: 100-160 parts of jasmine powder, 400-550 parts of water, 80-130 parts of whole konjac powder and 6-8 parts of sodium carbonate.

[0046] Preparation of jasmine powder: washing jasmine flowers, vacuum freezing, thawing, drying, milling, passing through an 80-mesh sieve, and sieving the materials to obtain jasmine powder.

[0047] Vacuum freezing: Freeze the cleaned jasmine flowers at -30°C to -40°C under vacuum for 10 hours;

[0048] Thawing: Place the vacuum-frozen jasmine flowers at 60°C to 70°C to dissolve quickly. It will not destroy the cells of jasmine flowers, maintain a stable fragrance, and can be easily adsorbed on the microporous surface.

[0049] Preparation of whole konjac powder: washing, peeling, ...

Embodiment 2

[0059] Embodiment 2, a kind of jasmine cigarette, is made of following raw materials: jasmine, konjac whole powder, water and coagulant; Jasmine is the powdery particle after processing; Coagulant is sodium carbonate;

[0060]Preparation of jasmine powder: washing jasmine flowers, vacuum freezing, thawing, drying, milling, passing through an 80-mesh sieve, and sieving the materials to obtain jasmine powder.

[0061] Vacuum freezing: Freeze the cleaned jasmine flowers at -30°C to -40°C under vacuum for 10 hours;

[0062] Thawing: Place the vacuum-frozen jasmine flowers at 60°C to 70°C to dissolve quickly. It will not destroy the cells of jasmine flowers, maintain a stable fragrance, and can be easily adsorbed on the microporous surface.

[0063] Preparation of whole konjac powder: washing, peeling, drying and milling fresh taro to get konjac whole powder, passing through an 80-mesh sieve, and sieving the materials to get konjac whole powder.

[0064] Flour making: prepared at...

Embodiment 3

[0073] Embodiment 3, a kind of jasmine cigarette, is made of following raw material: jasmine, konjac whole powder, water and coagulant; Jasmine is the powdery particle after processing; Coagulant is sodium carbonate;

[0074] Preparation of jasmine powder: washing jasmine flowers, vacuum freezing, thawing, drying, milling, passing through an 80-mesh sieve, and sieving the materials to obtain jasmine powder.

[0075] Vacuum freezing: Freeze the cleaned jasmine flowers at -30°C to -40°C under vacuum for 10 hours;

[0076] Thawing: Place the vacuum-frozen jasmine flowers at 60°C to 70°C to dissolve quickly. It will not destroy the cells of jasmine flowers, maintain a stable fragrance, and can be easily adsorbed on the microporous surface.

[0077] Preparation of whole konjac powder: washing, peeling, drying and milling fresh taro to get konjac whole powder, passing through an 80-mesh sieve, and sieving the materials to get konjac whole powder.

[0078] Flour making: prepared at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com