Laminated composite functional mask filter element, mask and preparation method of filter element

A functional, mask technology, applied in the field of masks, can solve the problems of inability to achieve micro-particles, adhesion limitation, extensive adsorption and filtration, etc., to expand adsorption and filtration capacity, improve comfort, and improve filtration and adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

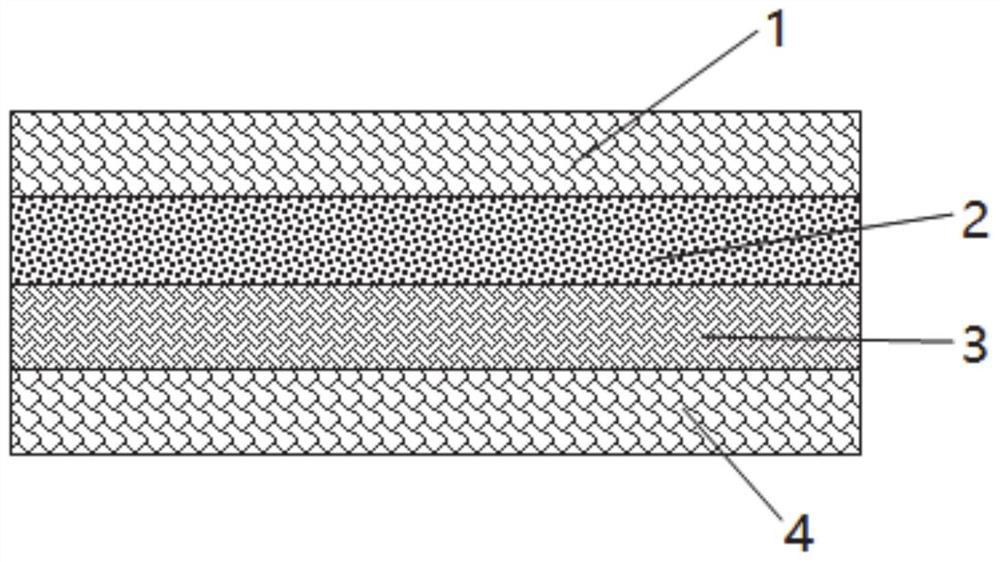

[0037] In a third aspect of the present invention, the preparation method of the above-mentioned laminated composite functional mask filter element is provided, comprising the steps of:

[0038] The antibacterial functional treatment is carried out on the activated carbon fiber layer to obtain the antibacterial filter layer;

[0039] Surface treatment of fiber monofilaments of spunbonded nonwoven fabrics to obtain a skin-friendly moisture-absorbing layer;

[0040] The protective layer, the antibacterial filter layer, the filter layer and the skin-friendly moisture-absorbing layer are superimposed in sequence, and then the carbon fiber is chopped and needled to form a whole.

[0041] In some embodiments, the method for carrying out antibacterial functionalization treatment to the activated carbon fiber layer comprises the following steps:

[0042] The activated carbon fiber layer is vacuum degassed at 120-140°C for 1-3 hours; vacuumize to extract the internal air.

[0043] Im...

Embodiment 1

[0056] A kind of functional mask filter core structure designed by laminated combination of the present invention, specifically adopts 20g / m 2 A spun-bonded non-woven fabric protective layer with a grammage of 0.6 gram is prepared from the polyester fiber in grammage.

[0057] Using T300 carbon fiber filament as raw material to prepare a specific surface area of 500m 2 / g monofilament surface average pore diameter 1.0nm, gram weight 20g / m 2 Active carbon fiber antibacterial filter layer, the weight of a single piece is controlled at 0.4 grams. The bacteriostatic functionalization treatment of activated carbon fiber, at first activated carbon fiber is carried out vacuum degassing treatment at 130 ℃ for 1 hour, adopts the aqueous solution of 1.5% concentration of nano-titanium dioxide to impregnate afterwards, 80 ℃ dry 2 hours.

[0058] Use polyester fiber to prepare fiber specific surface area of 0.01m 2 / g, bulk density 0.05g / cm3 Melt-blown non-woven fabric filter layer...

Embodiment 2

[0062] The present invention is a functional mask filter core structure with laminated combination design, specifically adopts 30g / m 2 The grammage of the acrylic fiber is used to prepare a spunbonded non-woven protective layer with a grammage of 0.9 gram.

[0063] Using T1000 carbon fiber filament as raw material to prepare a specific surface area of 2500m 2 / g monofilament surface average pore diameter 4.0nm, gram weight 30g / m 2 Active carbon fiber antibacterial filter layer, the weight of a single piece is controlled at 0.8 grams. Antibacterial functional treatment of activated carbon fibers, first degassing the activated carbon fibers at 130°C for 3 hours in vacuum, then impregnating them with a 2.5% aqueous solution of nano-silver, and drying at 80°C for 4 hours.

[0064] Selecting polyphenylene sulfide thermoplastic fibers to prepare fibers with a specific surface area of 0.1m 2 / g, bulk density 0.1g / cm 3 Melt-blown non-woven fabric filter layer, melt-blown non-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com