A Drilling Process for Ultra-Long Fine Pore Steel Pipes

A processing technology and fine hole technology, applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of difficult production of products that meet customer needs, lack of in-depth research, and inability to process, etc. Achieve the effects of enhancing influence and competitiveness, reflecting social value, and saving foreign exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 34CrNi used in the production of polyethylene equipment by Sinopec 3 MoVA ultra-high pressure alloy steel pipe is taken as an example, and the blank of this material is drilled. The outer diameter of the blank is generally Φ20-150mm, and the length is 15000mm;

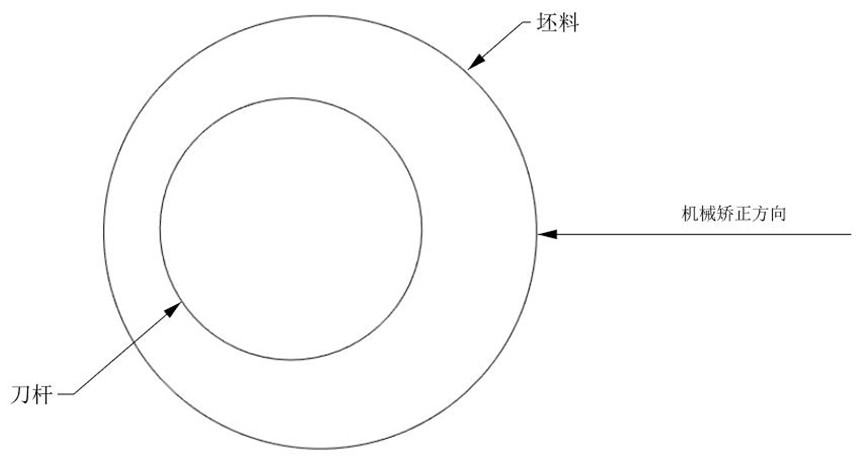

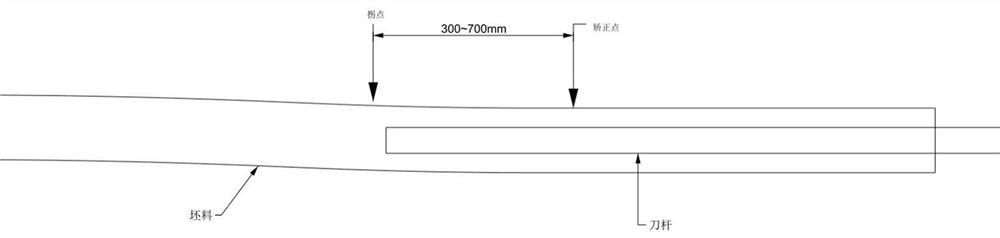

[0024]S1. Drilling preparation: lengthen the existing lathe bed or make drilling equipment with a bed length greater than 32 meters in length of ultra-long and fine-hole ultra-high pressure alloy steel pipe products; install the forged blank after turning into the drill On the hole equipment, the chucks and drill holders of the drilling equipment are used to fix the head and tail ends, and the center frame is used to fix along the length direction of the blank (that is, the axial direction). The center frame interval is 3m / piece, and the naked eye head Observe that the blank is basically horizontal at the end or tail end, and drill the hole with a special drilling tool that matches the size of the inner hole to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com