Self-adaption control method for laser engraving

An adaptive control, laser engraving technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as over-burning, inconsistent manufacturing quality, inability to adapt to machine tool processing speed, acceleration changes, etc., and has low experience requirements , The effect of saving process preparation time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention more clear, detailed description will be given below in conjunction with the accompanying drawings.

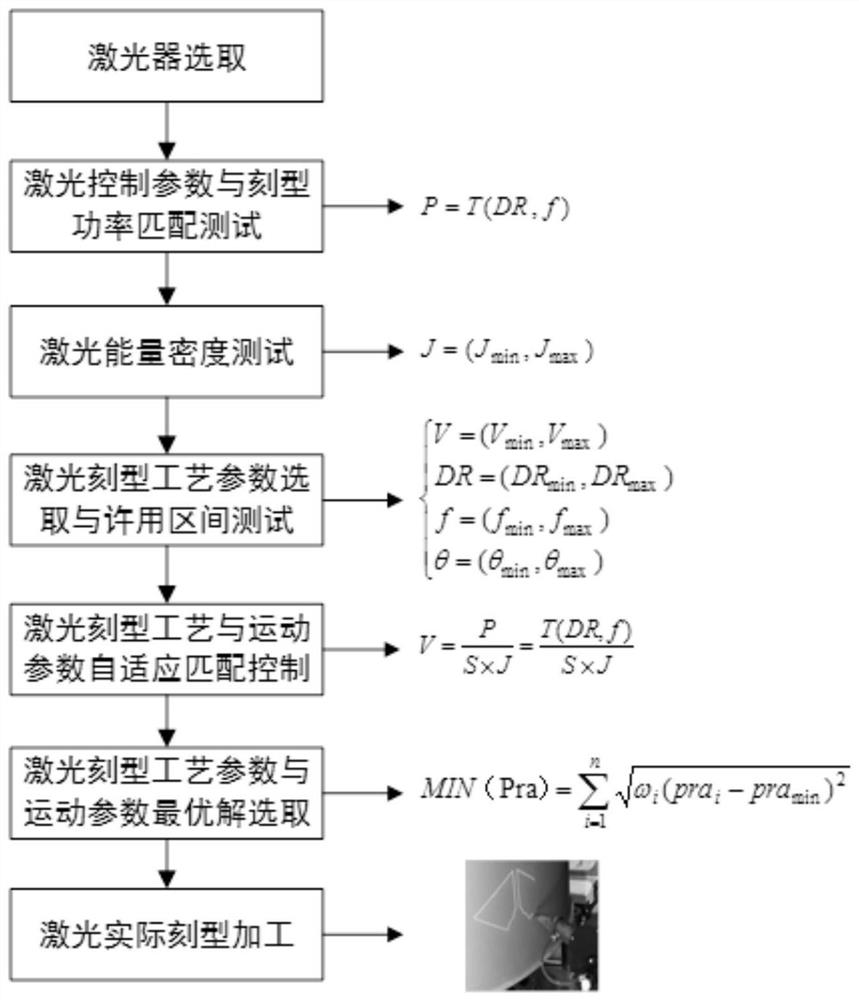

[0048] An adaptive control method for laser engraving, characterized in that,

[0049]STEP1: Selection of laser. For the laser engraving adhesive film and substrate material used in practice, analyze the actual mechanism of laser engraving, and select a laser with a suitable wavelength and power; for laser engraving where the main component of the laser engraving adhesive layer is organic matter, from the perspective of material and economy Generally, CO2 lasers are used for the angle, but other types of lasers can also be used;

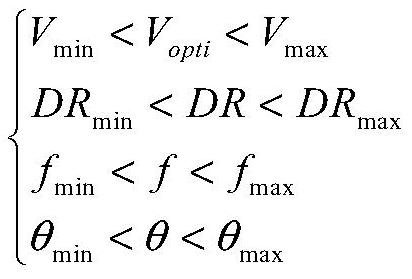

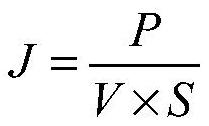

[0050] STEP2: Matching test of laser control parameters and engraving power. According to the nature of the laser itself, through the laser power tester, determine the actual laser output power P under different duty ratio DR and pulse frequency f; establ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com