Defective product treatment system for mobile phone film laminating machine

A processing system and laminating machine technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve problems such as the inability to work on the assembly line of the film laminating system, the inability to remove the film that cannot be air bubbles, and the inability to effectively detect air bubbles, etc., to achieve human identification or The effects of inaccurate shooting and recognition, increasing the success rate of film application, and improving the success rate of film application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

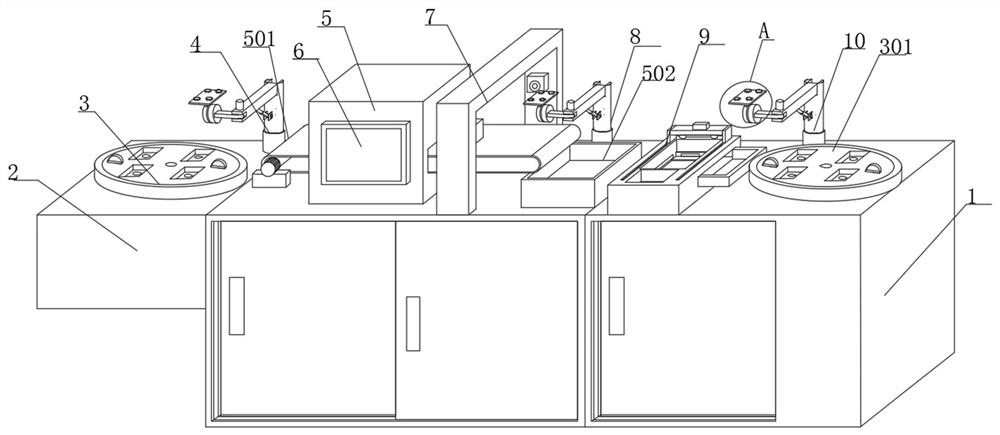

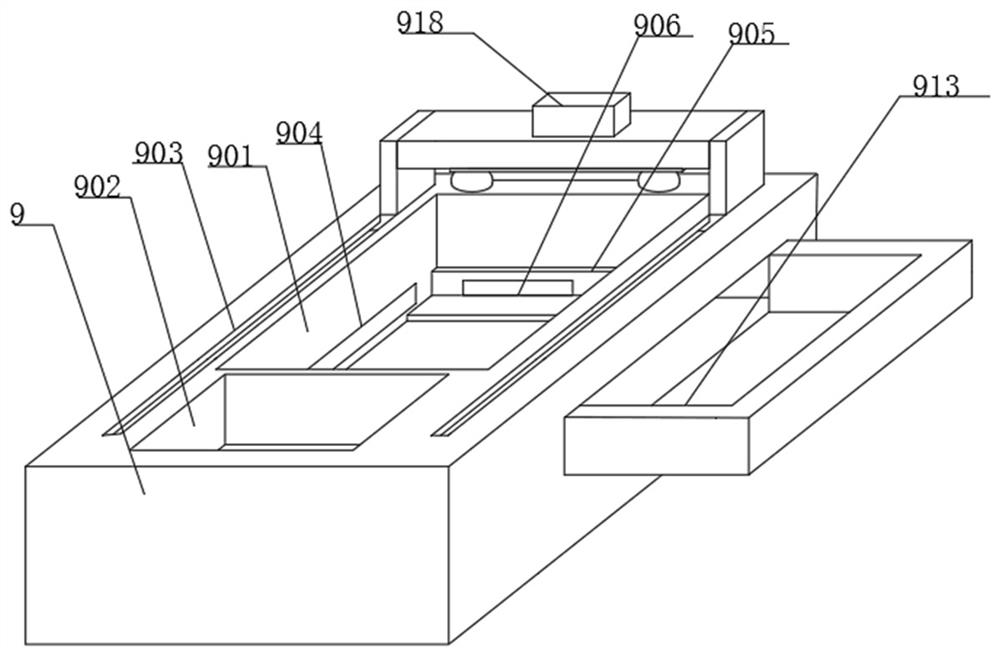

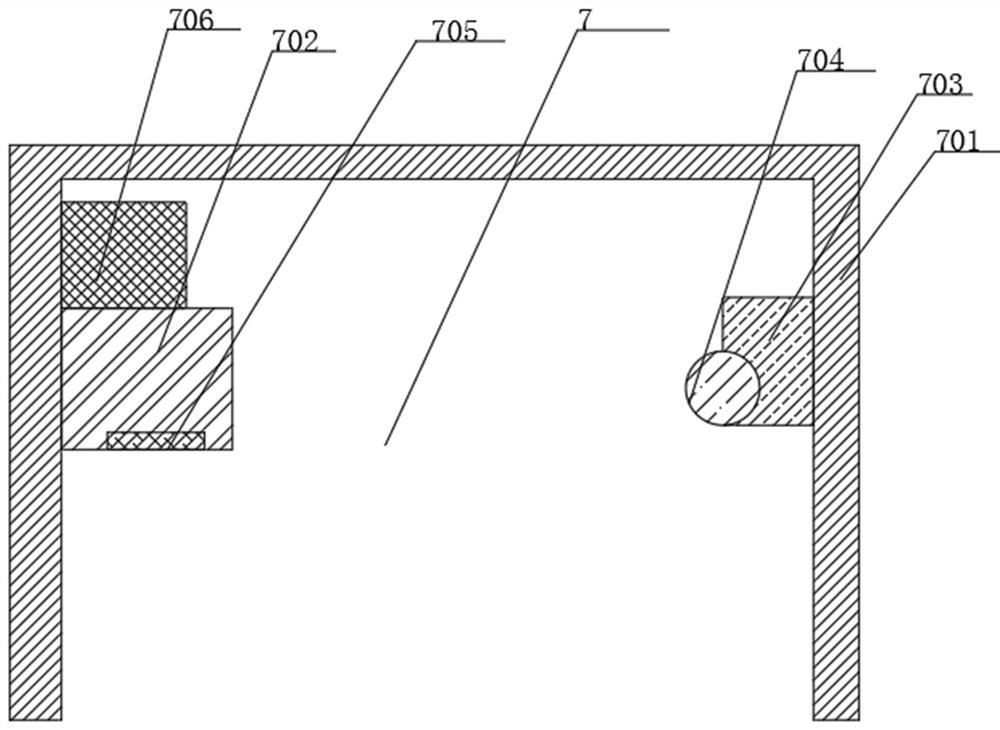

[0031] Such as Figure 1-8 As shown, a mobile phone film laminating machine includes a workbench (1), a fixed box (2) is fixedly installed on the left side of the workbench (1), and a first manipulator (4) is fixedly installed on the upper surface of the fixed box (2) , the upper surface of the workbench (1) is fixedly installed with a film sticking mechanism (5) and a defective product processing system. The defective product processing system includes a feeding mechanism (3), a control display screen (6), a detection mechanism (7), The second manipulator (8), the film-removing mechanism (9) and the third manipulator (10), the feeding mechanism (3) is suitable for providing mobile phones without film and storing the mobile phones processed by the film-removing mechanism (9), and controlling the display screen (6) It is suitable for controlling the operation of the entire device through the PLC system. The detection mechanism (7) is suitable for detecting bubbles on the mobile...

Embodiment 2

[0044] Such as Figure 1-8 As shown, a mobile phone film laminating machine includes a workbench (1), a fixed box (2) is fixedly installed on the left side of the workbench (1), and a first manipulator (4) is fixedly installed on the upper surface of the fixed box (2) , the upper surface of the workbench (1) is fixedly installed with a film sticking mechanism (5) and a defective product processing system. The defective product processing system includes a feeding mechanism (3), a control display screen (6), a detection mechanism (7), The second manipulator (8), the film-removing mechanism (9) and the third manipulator (10), the feeding mechanism (3) is suitable for providing mobile phones without film and storing the mobile phones processed by the film-removing mechanism (9), and controlling the display screen (6) It is suitable for controlling the operation of the entire device through the PLC system. The detection mechanism (7) is suitable for detecting bubbles on the mobile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com