Preparation method of calcium aspartate

A technology of calcium aspartate and aspartic acid, applied in the field of bioengineering, can solve the problems of low yield of calcium aspartate, poor solubility of calcium carbonate, and high price of calcium hydroxide, and achieve full utilization of resources, preparation of The method is simple and the effect of good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

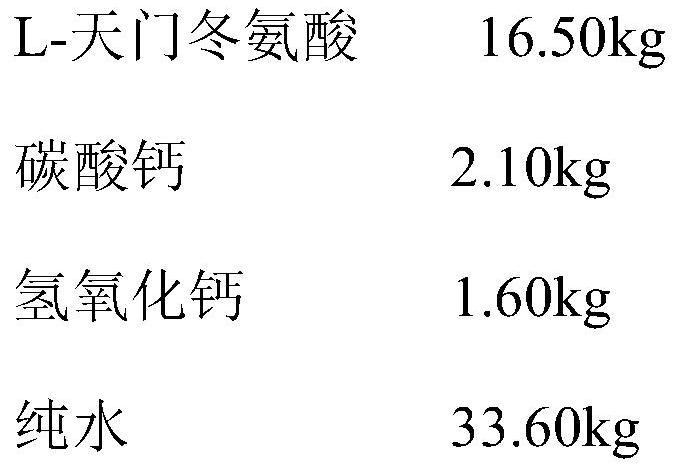

[0019]

[0020] Preparation:

[0021] S1. Batching reaction: add the above-mentioned raw materials into the reaction kettle in proportion, and react at 65°C and pH 5.3 for 0.5h; when the pH of the reaction solution reaches 6.1, keep it warm for 5min;

[0022] S2, primary homogenization: the reaction liquid enters the homogenizer after being filtered through a 100-mesh pipeline filter under the condition of 60MPa, and the feed rate is controlled to be 500L / h, and the filtrate is collected after homogenizing for 30 minutes;

[0023] S3, secondary homogenization: the filtrate obtained in step S2 is filtered under the condition of 90MPa using a 500-mesh screen and enters the homogenizer. The feed rate is controlled to be 120L / h, and the homogenization is 150min. The raw material solution was left standing overnight;

[0024] S4. Spray drying: under the condition of 200°C, use the instantaneous high-temperature technology of spray drying to dry the supernatant of calcium aspart...

Embodiment 2

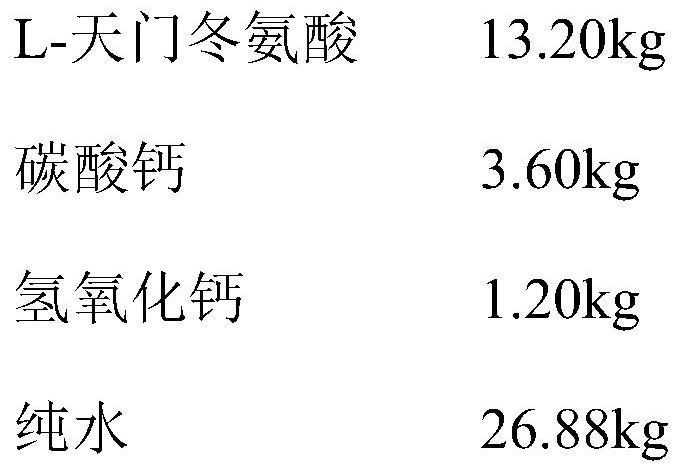

[0028]

[0029] Preparation:

[0030] S1. Batching reaction: add the above-mentioned raw materials into the reaction kettle in proportion, and react at 85°C and pH 6.0 for 1.0h; when the pH of the reaction solution reaches 6.5, keep warm for 10min;

[0031] S2, primary homogenization: the reaction liquid enters the homogenizer after being filtered through a 100-mesh pipeline filter under the condition of 80MPa, and the feed rate is 1000L / h, and the filtrate is collected after homogenizing for 60 minutes;

[0032] S3. Secondary homogenization: the reaction liquid after the first homogenization is filtered under the condition of 130MPa using a 500-mesh screen and then enters the homogenizer. The feed rate is 200L / h, and the homogenization is 300min. The solution was left to stand overnight;

[0033] S4. Spray drying: under the condition of 180°C, use the instant drying technology of spray drying to dry the supernatant of calcium aspartate after standing, and control the mois...

Embodiment 3

[0037]

[0038] Preparation:

[0039] S1. Batching reaction: add the above-mentioned raw materials into the reaction kettle in proportion, and react at 70°C and pH 5.5 for 1 hour; when the pH of the reaction solution reaches 6.5, keep it warm for 8 minutes;

[0040] S2, primary homogenization: the reaction solution enters the homogenizer after being filtered through a 100-mesh pipeline filter under the condition of 70MPa, the feed rate is 800L / h, and the filtrate is collected after homogenization for 60 minutes;

[0041] S3. Secondary homogenization: the reaction solution that has been homogenized once is filtered under the condition of 120MPa using a 500-mesh screen and then enters the homogenizer. The solution was left to stand overnight;

[0042] S4. Spray drying: under the condition of 250°C, use the instant drying technology of spray drying to dry the supernatant of calcium aspartate after standing, and control the moisture content of the product to not be higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com