Method for preparing taurine by high-voltage pulsed electric field assisted enzymolysis of freshwater mussel meat

A high-voltage pulsed electric field, assisted enzymatic hydrolysis technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of instability, extraction method of taurine, low extraction rate, etc. Waste, green and efficient production process, improved extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-voltage pulsed electric field-assisted enzymatic hydrolysis method for producing taurine, comprising the following steps:

[0030] (1) Raw material pretreatment:

[0031] Shell the clam meat to separate the viscera and meaty part, wash the meaty part, drain and homogenize it, and distribute it for equipment; (2) Wall breaking treatment:

[0032] Add distilled water to the pretreated mussel meat homogenate, the amount of distilled water added and the quality of the sample solution are added according to 1:1 (mL / g), and the mussel meat sample solution is obtained after intermittent treatment with a wall breaking machine for 2-3min. For distributing equipment;

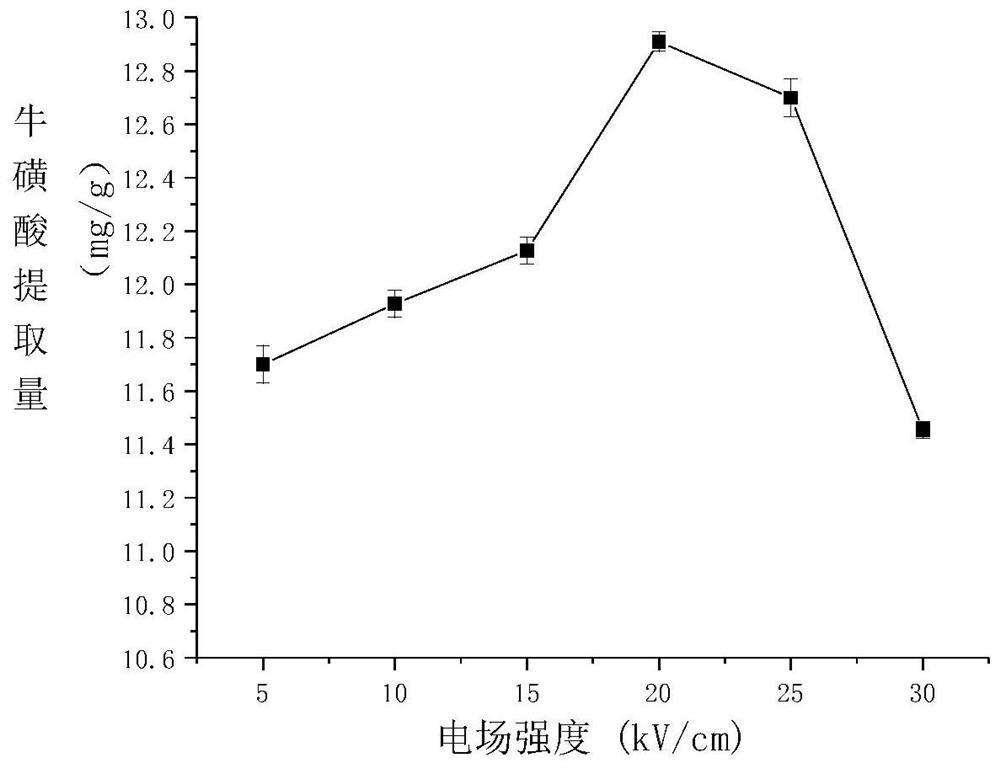

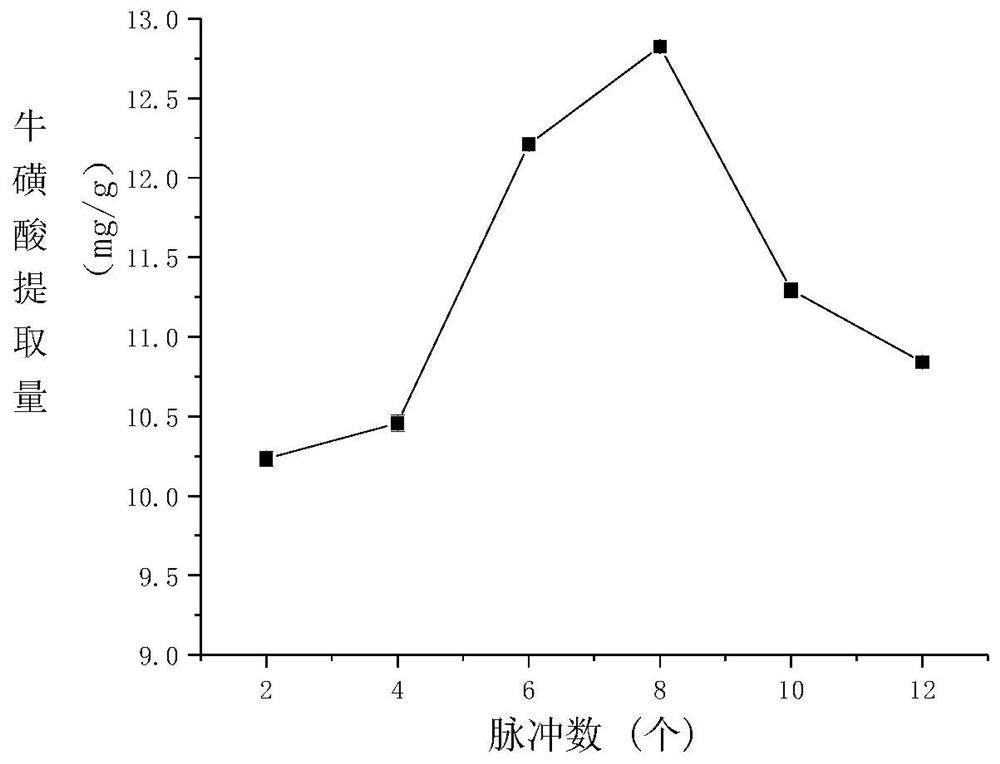

[0033] (3) High-voltage pulsed electric field treatment:

[0034] Take 4g of mussel meat sample liquid, add 32mL of distilled water to the sample liquid for homogenization, adjust the flow rate parameter of the peristaltic pump to 7mL / min after homogenization, and then perform pulse electric field treatmen...

Embodiment 2

[0047] A high-voltage pulsed electric field-assisted enzymatic hydrolysis method for producing taurine, comprising the following steps:

[0048] (1) Raw material pretreatment:

[0049] Shell the clam meat to separate the viscera and meaty part, wash the meaty part, drain and homogenize it, and distribute it for equipment; (2) Wall breaking treatment:

[0050] Add distilled water to the pretreated mussel meat homogenate, the amount of distilled water added and the quality of the sample solution are added according to 1:1 (mL / g), and the mussel meat sample solution is obtained after intermittent treatment with a wall breaking machine for 2-3min. For distributing equipment;

[0051] (3) High-voltage pulsed electric field treatment:

[0052] Take 4g mussel meat sample liquid, add 32mL distilled water to the sample liquid for homogenization, adjust the flow rate parameter of the peristaltic pump to 7mL / min after homogenization, and then perform pulse electric field treatment, pul...

Embodiment 3

[0065] A high-voltage pulsed electric field-assisted enzymatic hydrolysis method for producing taurine, comprising the following steps:

[0066] (1) Raw material pretreatment:

[0067] Shell the clam meat to separate the viscera and meaty part, wash the meaty part, drain and homogenize it, and distribute it for equipment; (2) Wall breaking treatment:

[0068] Add distilled water to the pretreated mussel meat homogenate, the amount of distilled water added and the quality of the sample solution are added according to 1:1 (mL / g), and the mussel meat sample solution is obtained after intermittent treatment with a wall breaking machine for 2-3min. For distributing equipment;

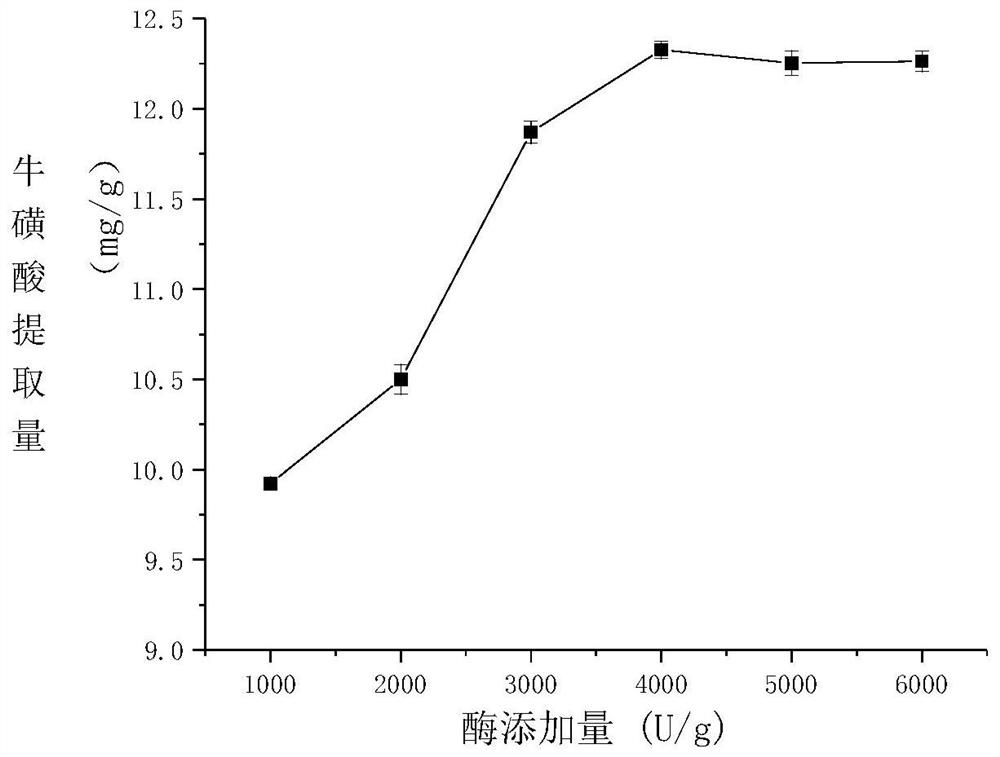

[0069] (3) High-voltage pulsed electric field treatment:

[0070] Take 4g of mussel meat sample liquid, add 32mL of distilled water to the sample liquid for homogenization, adjust the flow rate parameter of the peristaltic pump to 7mL / min after homogenization, and then perform pulse electric field treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com