Aging-resistant, high-viscosity and high-elasticity modified asphalt and preparation method thereof

A modified asphalt, anti-aging technology, used in building components, building insulation materials, buildings and other directions, can solve the problems of cracks, asphalt high-elasticity modification without improvement, etc., to achieve increased asphalt structural strength, high structural strength, extended use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

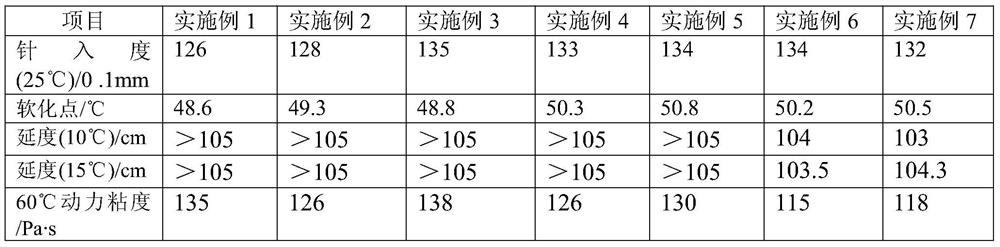

Examples

preparation example Construction

[0048]A preparation method of aging-resistant high-viscosity and high-elasticity modified asphalt, said method comprising the steps of:

[0049] S1. Preparation of the first component, heating the asphalt to 170-190°C through a heat exchanger, and transferring it to a stirring production tank;

[0050] S2, preparation of the second component, according to the weight ratio of 1:1:1, take thermoplastic polyurethane elastic particles with a particle size of 5-8mm, polyolefin particles and adhesive; brush the bottom of the square container with a layer of adhesive , then spread the polyolefin particles on the adhesive, and then brush a layer of adhesive on the surface of the polyolefin particles, and then spread the thermoplastic polyurethane elastic particles on the top of the polyolefin particles, and take them out after curing. Shake the particles in a way to divide them into smaller particle clusters; finally put the remaining binder and particle clusters into a stirring conta...

Embodiment 1

[0056] According to parts by weight, the first component of 90 parts by weight is prepared. The specific method is to get 89.9 parts of asphalt and 0.1 part of ultraviolet absorber and dispersant, mix asphalt, ultraviolet absorber and dispersant, and then heat The exchanger is heated to 170°C and transferred to the stirred production tank. According to parts by weight, prepare the second component of 3 parts by weight, get thermoplastic polyurethane elastic particles, polypropylene and Fischer-Tropsch hard wax whose particle diameter is 5mm according to the weight ratio of 1:1:1; First brush a layer of Fischer-Tropsch hard wax on the bottom of the container, then spread the polypropylene on the Fischer-Tropsch hard wax, then brush a layer of Fischer-Tropsch hard wax on the upper surface of the polypropylene, and then spread the thermoplastic polyurethane elastic particles on the The upper part of polypropylene, after being cured, take out and shake the particles by physical sh...

Embodiment 2

[0058] According to parts by weight, the first component of 90-98 parts by weight is prepared. The specific method is to take 91.9 parts of asphalt and 0.1 part of ultraviolet absorber and dispersant, mix asphalt, ultraviolet absorber and dispersant, and then After being heated to 180°C by a heat exchanger, it is transferred to a stirring production tank. According to parts by weight, prepare the second component of 4 parts by weight, according to the weight ratio of 1:1:1, get thermoplastic polyurethane elastic particles, ethylene copolymer and natural rubber with a particle diameter of 6mm; place the bottom of the square container First brush a layer of natural rubber, then spread the ethylene copolymer on the natural rubber, then brush a layer of natural rubber on the surface of the ethylene copolymer, then spread the thermoplastic polyurethane elastic particles on the upper part of the ethylene copolymer, take it out after curing The particles are shaken by physical shakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com