Supercritical carbon dioxide fluid flash explosion machine

A carbon dioxide and supercritical technology, applied in the direction of sustainable manufacturing/processing, solvent dyeing, climate sustainability, etc., can solve problems such as rare practical applications, and achieve high-efficiency flash explosion treatment, energy saving, efficient separation and recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

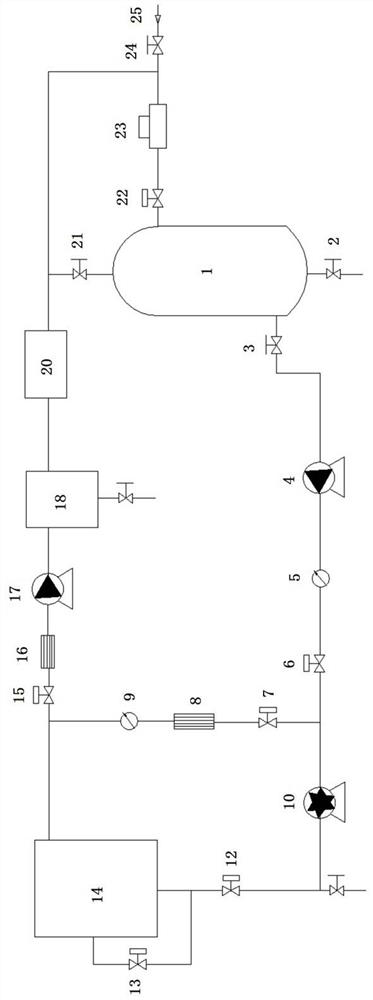

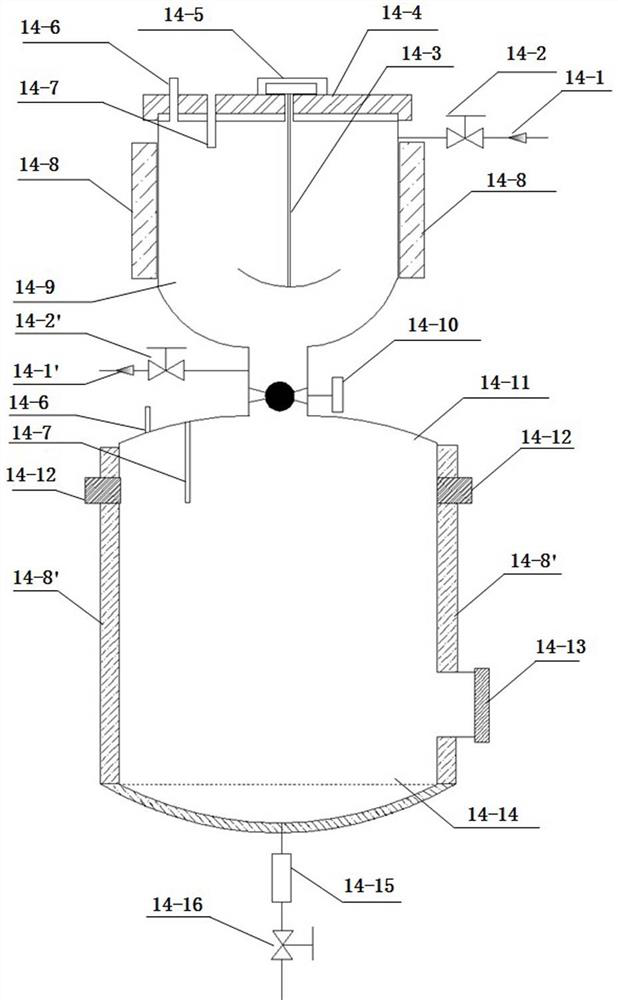

[0022] The invention provides a supercritical carbon dioxide fluid flash explosion machine, which includes a high-temperature and high-pressure fluid flash explosion system, a carbon dioxide medium pressurization system, a circulation treatment system, and a carbon dioxide separation and recovery system. The high-temperature and high-pressure fluid flash explosion system includes a high-temperature and high-pressure fluid processing area and a fluid flash explosion area, which are connected through passages equipped with flash explosion ball valves or other quick-opening valves. The high-temperature and high-pressure fluid processing area of the high-temperature and high-pressure fluid flash explosion system is connected to the circulation processing system through pipelines, and the fluid flash explosion area of the high-temperature and high-pressure fluid flash explosion system is connected to the circulation treatment system through another pipeline; one end of the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com