Mining roadway repair robot

A robot and roadway technology, applied in tunnels, mining devices, mining equipment, etc., can solve the problems of reducing the safety factor of mine construction, on-site chaos, waste of human, material and financial resources, and achieve the effect of saving man-machine investment and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

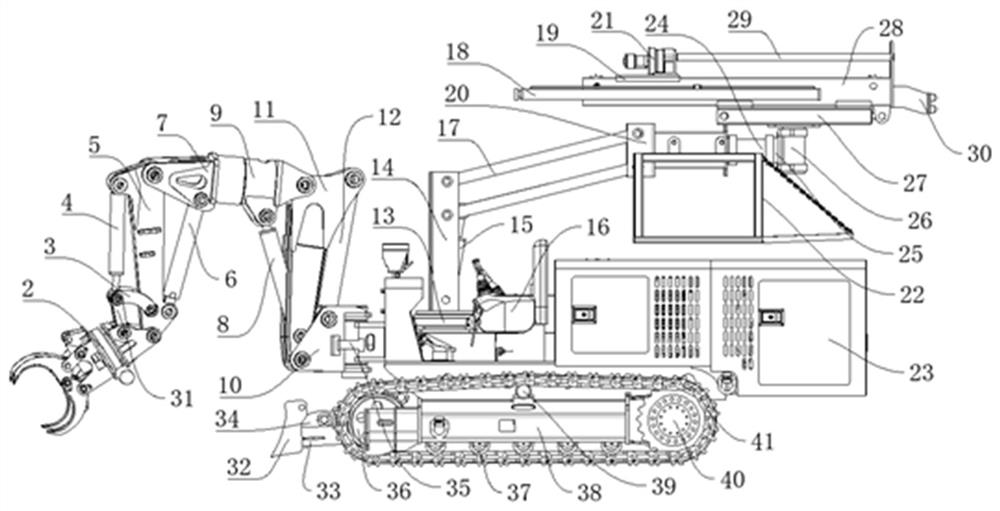

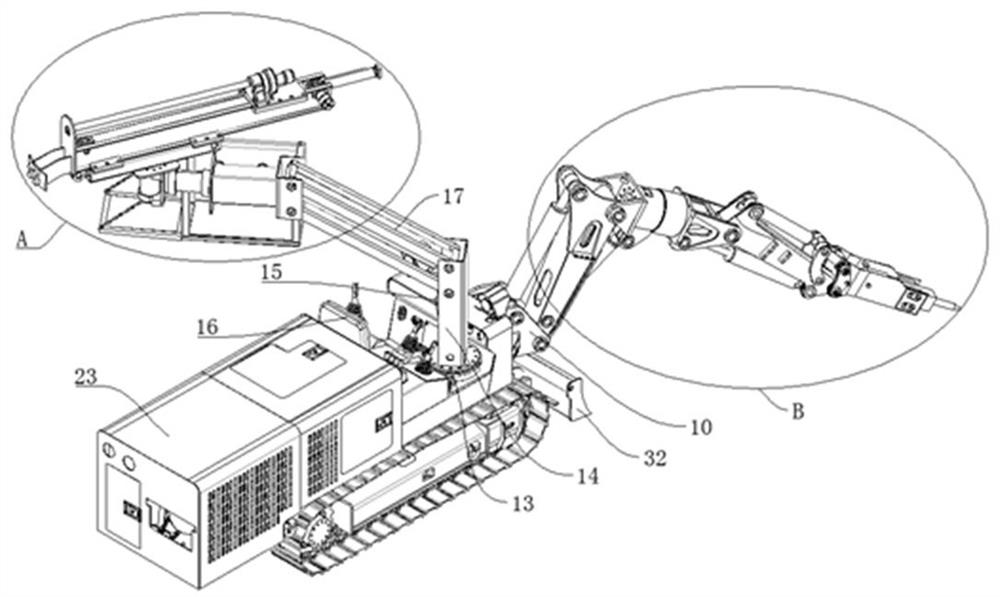

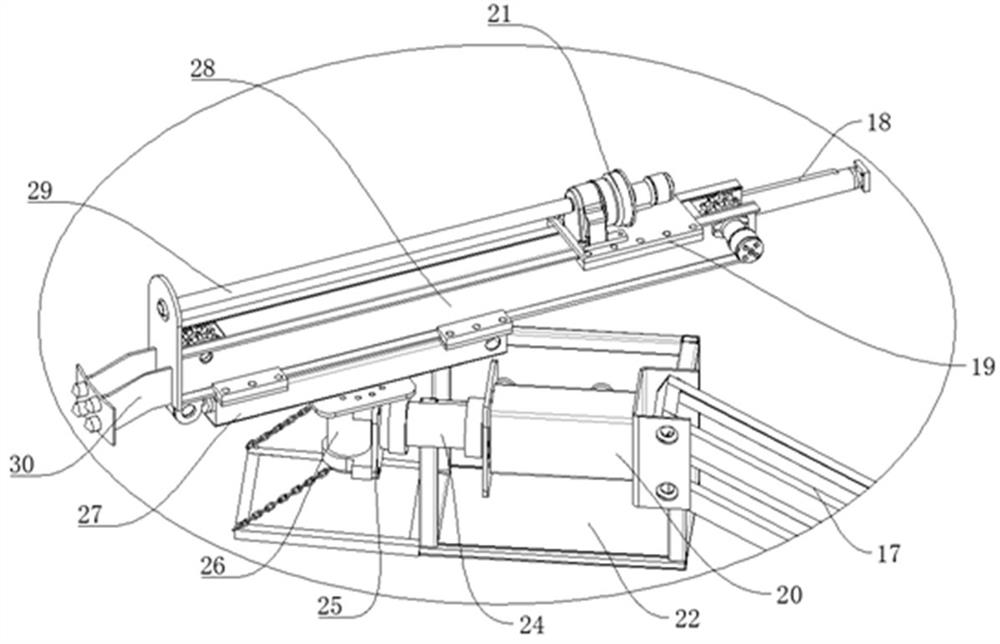

[0039] refer to Figure 1-12 , a mining roadway repair robot, including a working platform base, and also includes:

[0040] The main robot arm is provided with a steering seat 10, a three-section working arm, and a mechanical arm part. The three-section working arm is connected to the mechanical arm part. The three-section working arm is rotatably connected to the steering seat 10, and the steering seat 10 is rotatably connected to the working platform. On the base, the steering seat 10 is provided with a side-turn oil cylinder 35 for driving the steering seat 10 to rotate, and the cylinder body and the piston rod head of the side-turn oil cylinder 35 are connected to the working platform base and the steering seat 10 in rotation, so that the steering seat 10 can be rotated Drive the three-section working arm to swing sideways, and the large swing can improve the working range of the mechanical arm;

[0041] The mechanical arm parts mainly include:

[0042] refer to Figur...

Embodiment 2

[0070] refer to Figure 1-12 , a mining roadway repair robot, which is basically the same as that of Embodiment 1. Furthermore, a wireless remote control programmer can also be installed on the robot. The wireless remote control programmer is a prior art, and will not be repeated here. It can precisely fine-tune the angles of the first rotary reducer 13, the second rotary reducer 24, the third rotary reducer 26, and the three-section working arm to improve the accuracy of construction

[0071] The wireless remote control programmer has manual and automatic functions. In the manual state, the angle can be fine-tuned to locate the origin; the input parameters can be permanently saved to prevent future construction and use without repeated programming;

[0072] The motor speed and the hydraulic flow rate of the hydraulic device are controlled by the wireless remote control programmer. Input parameters on the wireless remote control programmer. The larger the input value, the grea...

Embodiment 3

[0074] refer to Figure 1-12 , a mining roadway repair robot, which is basically the same as that of Embodiment 2, and furthermore, a horizontal posture adjustment system is installed on the chassis frame 38, and the horizontal posture adjustment system is a prior art, and will not be repeated here. No matter how the chassis frame 38 tilts, the vehicle body will remain horizontal; the level adjustment disc is set in the middle of the chassis frame 38 and the vehicle body, and the level measurement sensor is installed at the bottom of the vehicle body platform. The horizontal adjustment disc automatically adjusts the horizontal angle; the horizontal posture adjustment system is concealed and softly installed between the chassis frame 38 and the vehicle body platform, and is not separated from each other and is mutually positionally constrained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com