Method and device for reducing stray light

A technology of stray light and light source, which is applied in the field of optical color measurement, can solve the problems affecting the accuracy of energy detection and detection accuracy, and achieve the effects of reducing the difference between platforms, saving costs, and reducing the formation of stray light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

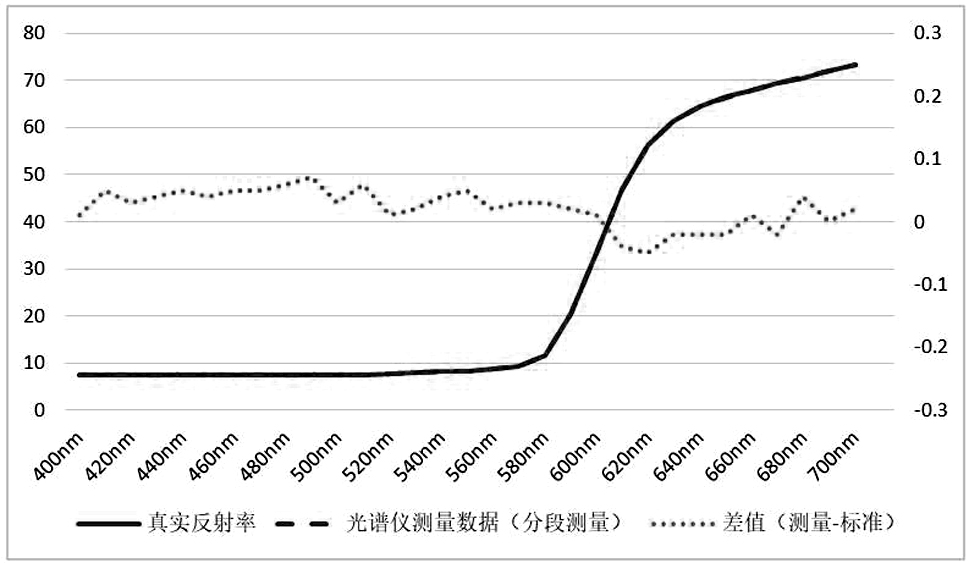

[0035] Divide the illumination light source into multiple segments within the measurement range for measurement (≥ 2 segments), add different optical filters 1 at the front end of the segmented light source 2, and measure in segments.

[0036] Take the three-segment measurement range as an example, such as Figure 1-3 As shown, select 3 groups of lighting LED lamps as the segmented light source 2 (full-spectrum LED, combined LED, halogen lamp, and xenon lamp can be used for this light source), among which, the first group of segmented light source 2 meets the spectral range of 360-510nm and has sufficient Spectral energy, the second group of segmented light sources 2 meets the spectral range of 490-610nm and has sufficient spectral energy, and the third group of segmented light sources 2 meets the requirement of 590-790nm and has sufficient spectral energy.

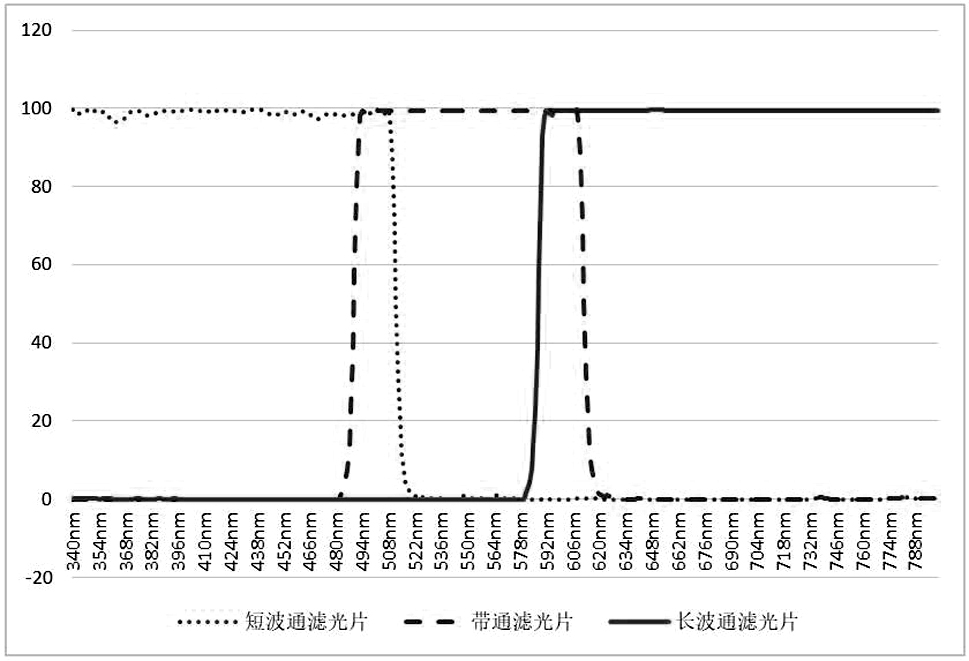

[0037] Add a short-wave pass filter 1 at the front end of the first group of segmented light sources 2, the working ran...

Embodiment 2

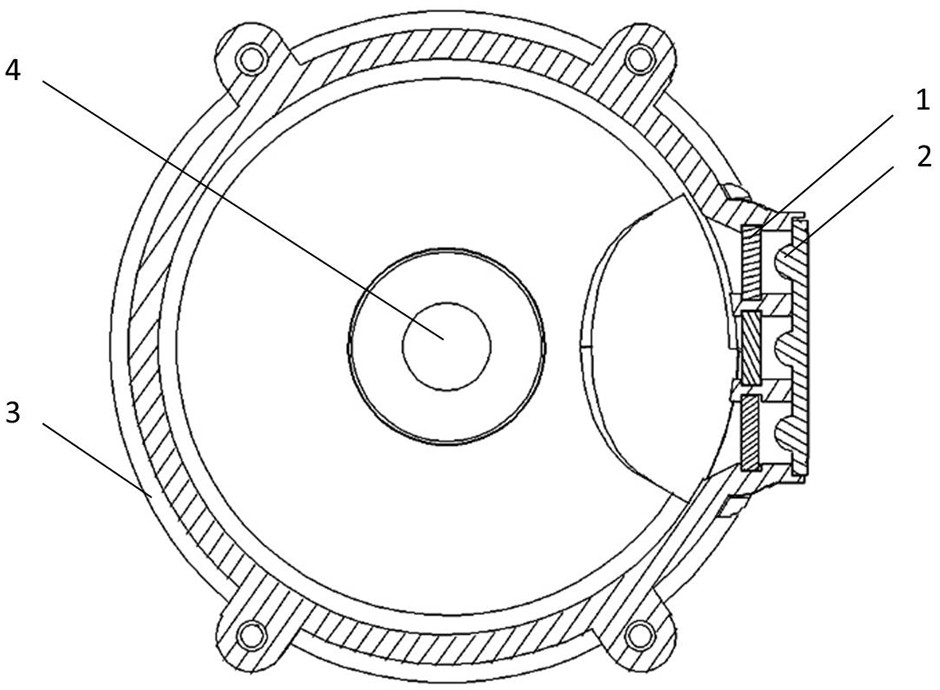

[0043]The lighting source uses a full-spectrum light source 7 within the measurement range (full-spectrum LED, combined LED, halogen lamp, xenon lamp, etc.), and the full-spectrum light source 7 irradiates the sample under test (or irradiates it through the measuring port 4 after being homogenized by the integrating sphere 3). The measured sample) is reflected to the spectral sensor 6, and multiple optical filters 1 (≥2 types) are added to the front end of the spectral sensor 6. The optical filter 1 is installed on the shutter 5, and the incident light of the spectral sensor 6 is switched by the movement of the shutter 5. The filter 1 at the front of the hole (it can also be a filter rotating wheel to switch the filter at the front of the spectral sensor 6).

[0044] Taking three kinds of filters as an example, such as Figure 2-4 As shown, 1. Shortwave pass filter 1, working range 360-510nm, cutoff range 510-800nm; 2. Bandpass filter 1, working range 490-610nm, cutoff range 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com