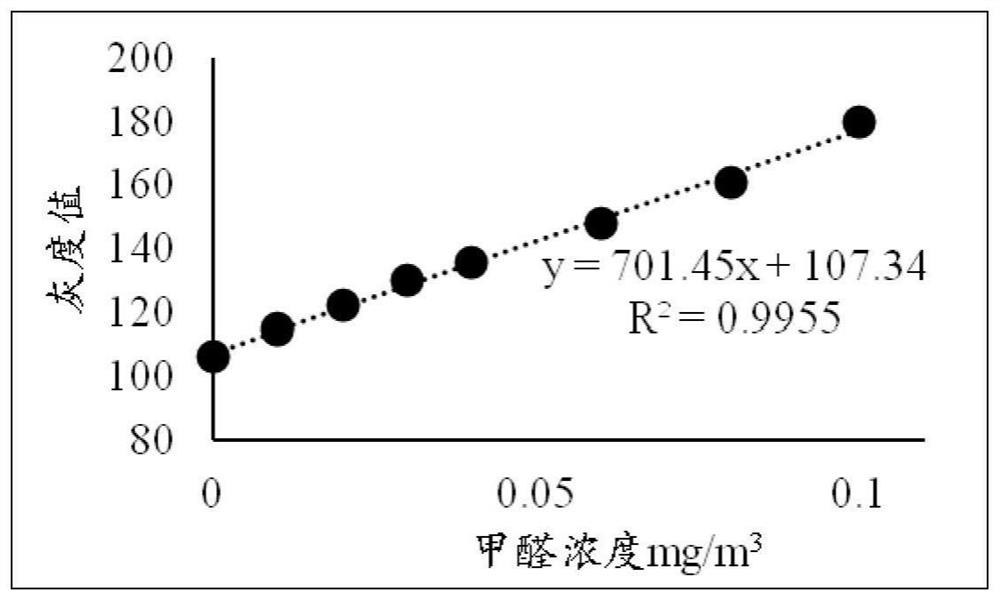

Fluorescent fiber for detecting formaldehyde and preparation method thereof

A fluorescent fiber and formaldehyde technology, applied in fiber processing, fluorescence/phosphorescence, fiber chemical characteristics, etc., can solve the problems of unfavorable detection, low sensitivity, and low promotion, and achieve the effects of improving stability, increasing sensitivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Step 1: (1) Under nitrogen atmosphere, disperse 3mmol of 4-bromo-1,8-naphthalene dicarboxylic anhydride in 50mL of ethanol solvent, add 3mmol of hydrazine hydrate dropwise, set the temperature at 82°C, and reflux for 6 hours, Cool to room temperature, filter and wash to obtain the crude product; (2) under a nitrogen atmosphere, dissolve 130 mg of the crude product in ethylene glycol monomethyl ether in turn, add 65 mg of hydrazine hydrate and 105 mg of potassium carbonate, set the temperature to 110 ° C, and reflux for 6 Hours; Ethylene glycol monomethyl ether was distilled off under reduced pressure, and methanol / dichloromethane was used for auxiliary chromatography, and ethanol crystallized to obtain the AHB fluorescent compound.

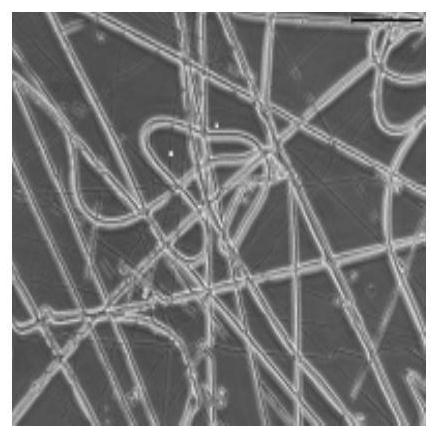

[0074] Step 2: Disperse 3 mg of AHB fluorescent compound evenly in 2 mL of dimethyl sulfoxide to obtain a solution A with a concentration of 1.5 g / L; dissolve polycaprolactone in 4 mL of chloroform to obtain a 25% solution B; Mix solution A...

Embodiment 2

[0077] Step 1: (1) Under nitrogen atmosphere, disperse 3mmol of 4-bromo-1,8-naphthalic anhydride in 50mL of ethanol solvent, add 3mmol of hydrazine hydrate dropwise, set the temperature at 80°C, and reflux for 7 hours, Cool to room temperature, filter and wash to obtain the crude product; (2) under nitrogen atmosphere, dissolve 130 mg of the crude product in ethylene glycol monomethyl ether successively, add 65 mg of hydrazine hydrate and 105 mg of potassium carbonate, set the temperature to 105 ° C, and reflux for 6 Hours; Ethylene glycol monomethyl ether was distilled off under reduced pressure, and methanol / dichloromethane was used for auxiliary chromatography, and ethanol crystallized to obtain the AHB fluorescent compound.

[0078] Step 2: Disperse 2.5 mg of AHB fluorescent compound evenly in 2 mL of dimethyl sulfoxide to obtain a solution A with a concentration of 1.25 g / L; dissolve polycaprolactone in 4 mL of chloroform to obtain a 25% solution B ; Mix solution A and so...

Embodiment 3

[0081] Step 1: (1) Under nitrogen atmosphere, disperse 3mmol of 4-bromo-1,8-naphthalene dicarboxylic anhydride in 50-60mL of ethanol solvent, add dropwise 3mmol of hydrazine hydrate, set the temperature at 85°C, and reflux for 5 hour, cooled to room temperature, filtered and washed to obtain the crude product; (2) under nitrogen atmosphere, 130 mg of the crude product was dissolved in ethylene glycol monomethyl ether successively, 65 mg of hydrazine hydrate and 105 mg of potassium carbonate were added, and the set temperature was 115° C. Reflux for 4 hours; ethylene glycol monomethyl ether was distilled off under reduced pressure, and methanol / dichloromethane was used for auxiliary chromatography, and ethanol crystallized to obtain the AHB fluorescent compound.

[0082] Step 2: Disperse 2mg of AHB fluorescent compound evenly in 2mL of dimethyl sulfoxide to obtain a solution A with a concentration of 1g / L; dissolve polycaprolactone in 4mL of chloroform to obtain a 25% solution B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com