Method for testing sodium ion transmission capacity of chlor-alkali membrane

A chlor-alkali ion membrane and sodium ion technology, which is applied in measurement devices, material separation, instruments, etc., can solve problems such as insufficient ability to transfer sodium ions, and achieve the effects of clear, fast and clear detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for testing chlor-alkali membrane of the present invention to transmit sodium ion ability may further comprise the steps:

[0031] 1) Chlor-alkali ion membrane pretreatment

[0032] Cut the chlor-alkali ion membrane into a sample of 60mm×60mm, rinse the cut chlor-alkali ion membrane with pure water, and soak it in 58.5g / L NaCl solution for 3h.

[0033] 2) Assembly of chlor-alkali ion membrane in diffusion dialysis device

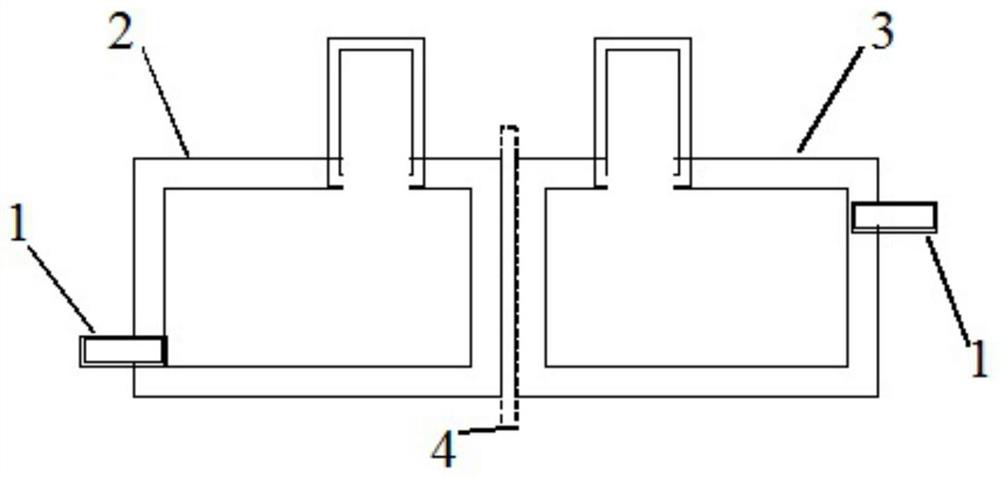

[0034] Take the sample after pretreatment, dry its surface solution with filter paper, such as figure 1 As shown, the chlor-alkali ion membrane is assembled between the interconnected dialysis chamber 2 and the diffusion chamber 3, and the dialysis chamber 2 and the diffusion chamber 3 are connected to the channels with holes in the corresponding positions. figure 1 The schematic diagram of the structure is easy to understand and will not be repeated here. The sulfonic acid side of the chlor-alkali membrane faces the dialysis chamber 2, a...

Embodiment 2

[0041] The method for testing chlor-alkali membrane of the present invention to transmit sodium ion ability may further comprise the steps:

[0042] 1) Chlor-alkali ion membrane pretreatment

[0043] Cut the chlor-alkali ion membrane into a sample of 60mm×60mm, rinse the cut chlor-alkali ion membrane with pure water, and soak it in 58.5g / L NaCl solution for 3h.

[0044] 2) Assembly of chlor-alkali ion membrane in diffusion dialysis device

[0045] Take the sample after pretreatment, dry its surface solution with filter paper, assemble the chlor-alkali ion membrane between the interconnected dialysis chamber 2 and diffusion chamber 3, as figure 1 As shown, the chlor-alkali ion membrane is assembled between the interconnected dialysis chamber 2 and the diffusion chamber 3, and the dialysis chamber 2 and the diffusion chamber 3 are connected to the channels with holes in the corresponding positions. figure 1 The schematic diagram of the structure is easy to understand and will ...

Embodiment 3

[0052] The method for testing chlor-alkali membrane of the present invention to transmit sodium ion ability may further comprise the steps:

[0053] 1) Chlor-alkali ion membrane pretreatment

[0054] Cut the chlor-alkali ion membrane into a sample of 60mm×60mm, rinse the cut chlor-alkali ion membrane with pure water, and soak it in 300g / L NaCl solution for 3h.

[0055] 2) Assembly of chlor-alkali ion membrane in diffusion dialysis device

[0056] Take the sample after pretreatment, dry its surface solution with filter paper, assemble the chlor-alkali ion membrane between the interconnected dialysis chamber 2 and diffusion chamber 3, as figure 1 As shown, the chlor-alkali ion membrane is assembled between the interconnected dialysis chamber 2 and the diffusion chamber 3, and the dialysis chamber 2 and the diffusion chamber 3 are connected to the channels with holes in the corresponding positions. figure 1 The schematic diagram of the structure is easy to understand and will n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com