Method for designing focal length instrument of electrodeless zoom lens

A design method and infinitely variable technology, applied in the directions of instruments, optics, optical components, etc., can solve the problems of difficult assembly, unable to achieve infinite zoom, unable to measure the focal length, etc., and achieve the effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

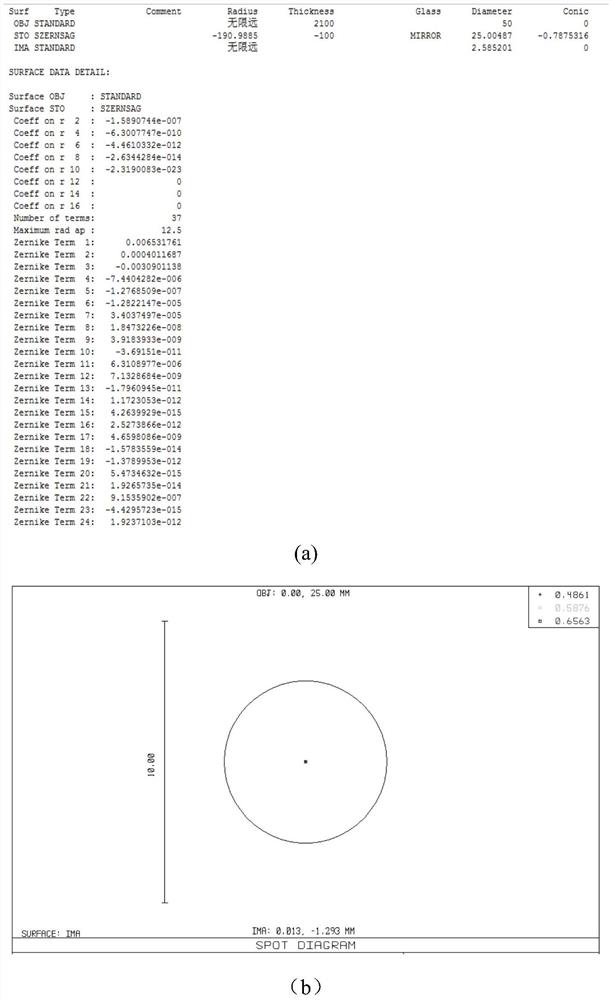

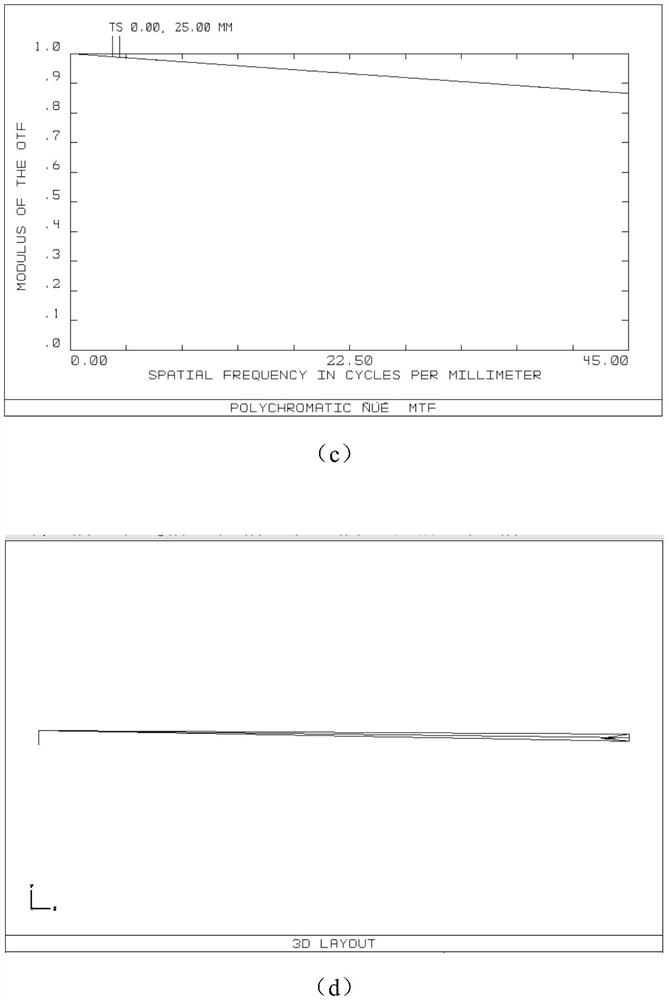

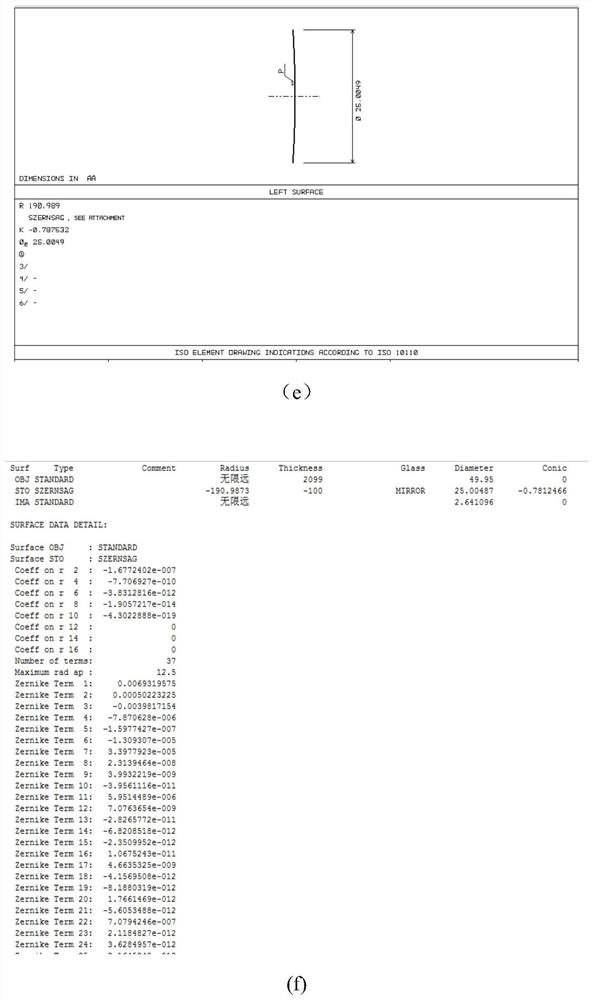

[0023] The invention comprises the following steps: 1. Firstly, the structure of the free-form surface mirror is designed by adopting an optical system design method. The surface shape of the free-form surface is characterized by Zernike polynomials, and the polynomial coefficients corresponding to the focal length of a measured lens are fitted by ZEMAX software to obtain a surface structure that meets the aberration requirements.

[0024] 2. Then sample and fit the series of Zernike polynomial coefficients corresponding to the focal length ranges between -1000mm---2mm and 2mm-1000mm.

[0025] 3. Finally, use the obtained Zernike polynomial to build a micro-matrix free-form mirror, and use a computer to control the electric drive to scan the surface shape of the free-form mirror. When a clear image with the largest image height appears on the CCD, it will be output by the computer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com