Method for growing atypical tertiary dendrites in directionally solidified peritectic alloy

A directional solidification, atypical technology, applied in computer materials science, instrumentation, informatics, etc., can solve problems such as undiscovered tertiary dendrite arm growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

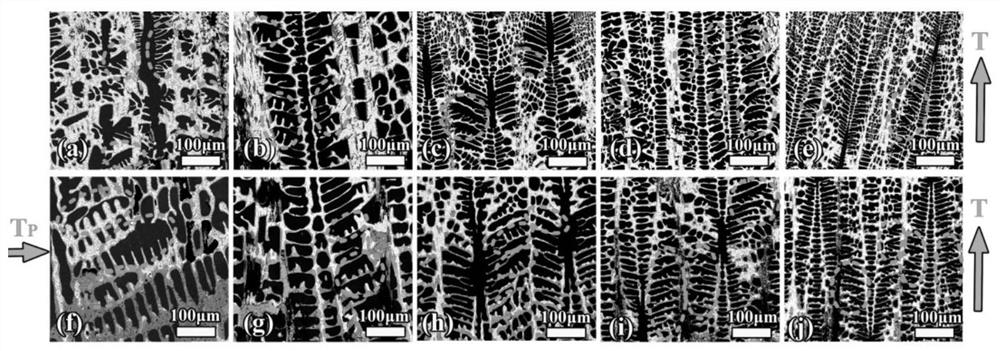

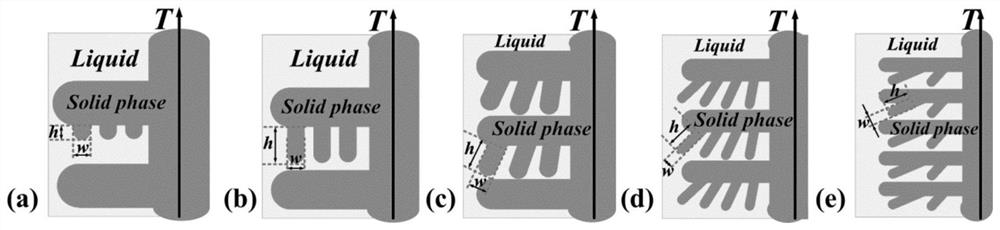

Embodiment

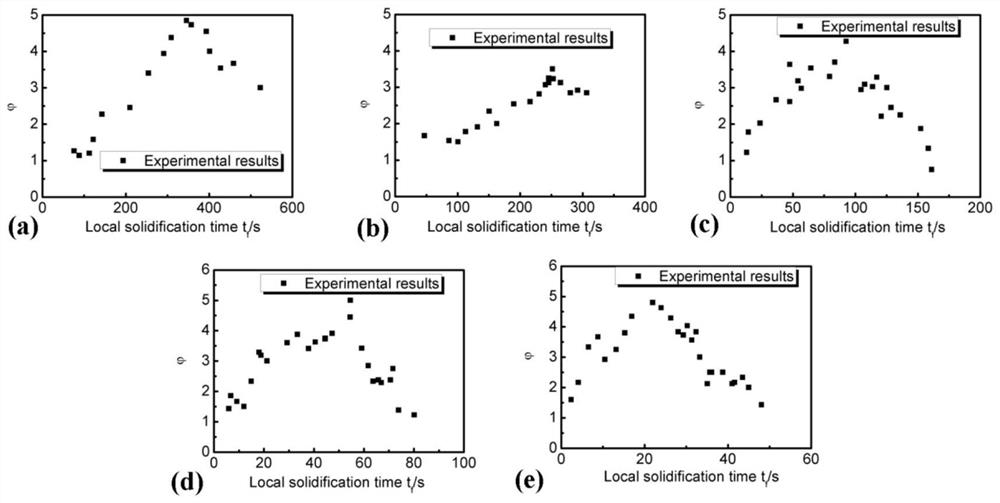

[0142] First, the as-cast Sn-40at.%Mn alloy was induction melted from pure manganese and pure tin with a purity of 99.9%. Rods with a diameter of 3 mm and a length of 110 mm were then cut from the ingot. During directional solidification, the rod is first placed in the Al 2 o 3 tube, and the temperature of the rod was raised to 800°C to melt it, and then the sample was left to stand in a Bridgman type furnace for 30 minutes. Second, the rods were grown at a range of growth rates: 5 μm / s, 10 μm / s, 30 μm / s, 50 μm / s and 100 μm / s. Thirdly, when the growth distance reaches 50mm, put the tube into liquid Ga-In-Sn alloy for quenching. From the PtRh30-PtRh6 temperature curve, the temperature gradient close to the solid / liquid interface is 21K / mm. The samples were thereafter sliced and polished for further analysis by scanning electron microscopy (SEM (Quanta-200)).

[0143] Equilibrium solidification of Sn-40at.%Mn alloy at T L = At 745°C, Mn is mainly precipitated 2-x Sn pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com