Double-rotor single-stator disc type motor

A disc motor, single stator technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of winding insulation damage, high processing technology, difficult implementation, etc., to prevent axial movement, improve heat dissipation capacity, power The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

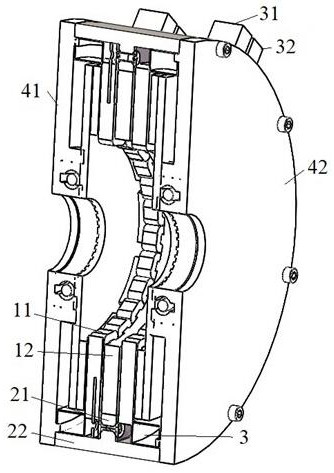

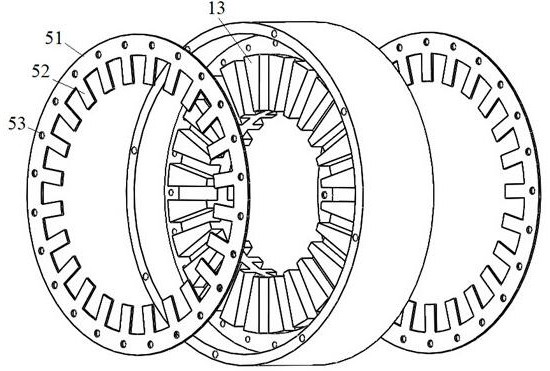

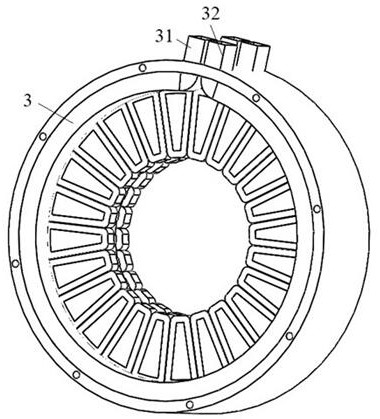

[0026] Such as Figure 1 to Figure 3 As shown, the dual-rotor single-stator disc motor of the present invention, on the one hand, takes into account the characteristics of the amorphous alloy stator being thin, brittle and hard, and solves its fixing problem; Cooling system under the premise of motor power density.

[0027] In this embodiment, a double-rotor single-stator slotted disc motor is used for illustration, but it is not limited thereto. Other disc motors may also adopt the cooling method and stator fixing method of the present invention.

[0028] The disc motor comprises a casing 22, a front end cover 41 and a rear end cover 42, a winding 11 and a stator core 12 are installed in the cavity formed by the casing 22, the front end cover 41 and the rear end cover 42, and the stator core 12 is provided with Stator slot 13. Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com