Meat product sterile processing workshop system and meat product sterile processing technology

A technology for processing workshops and meat products, which is applied in the direction of processed meat, meat processing equipment, food preservation, etc. It can solve the problems of poor taste of meat products and the inability of the bottom to be heated evenly and fully, and achieve a uniform and uniform temperature suitable for large-scale promotion and application. Reasonable effect of heating and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

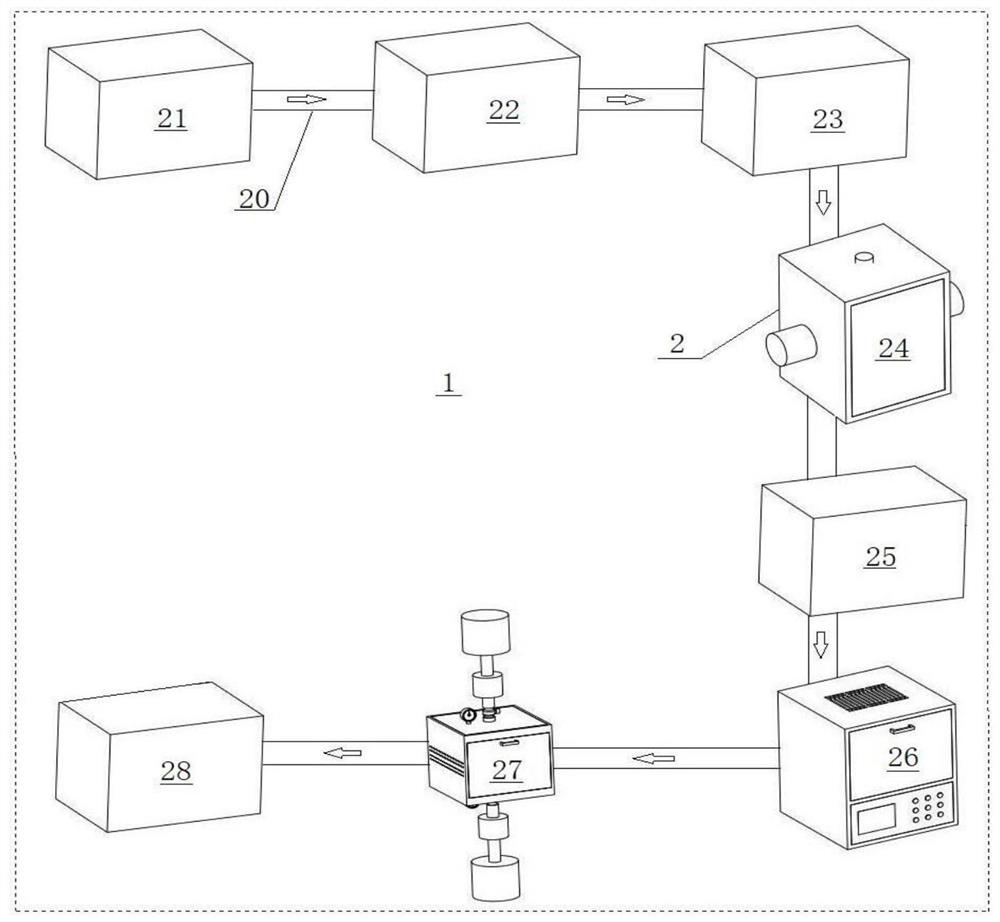

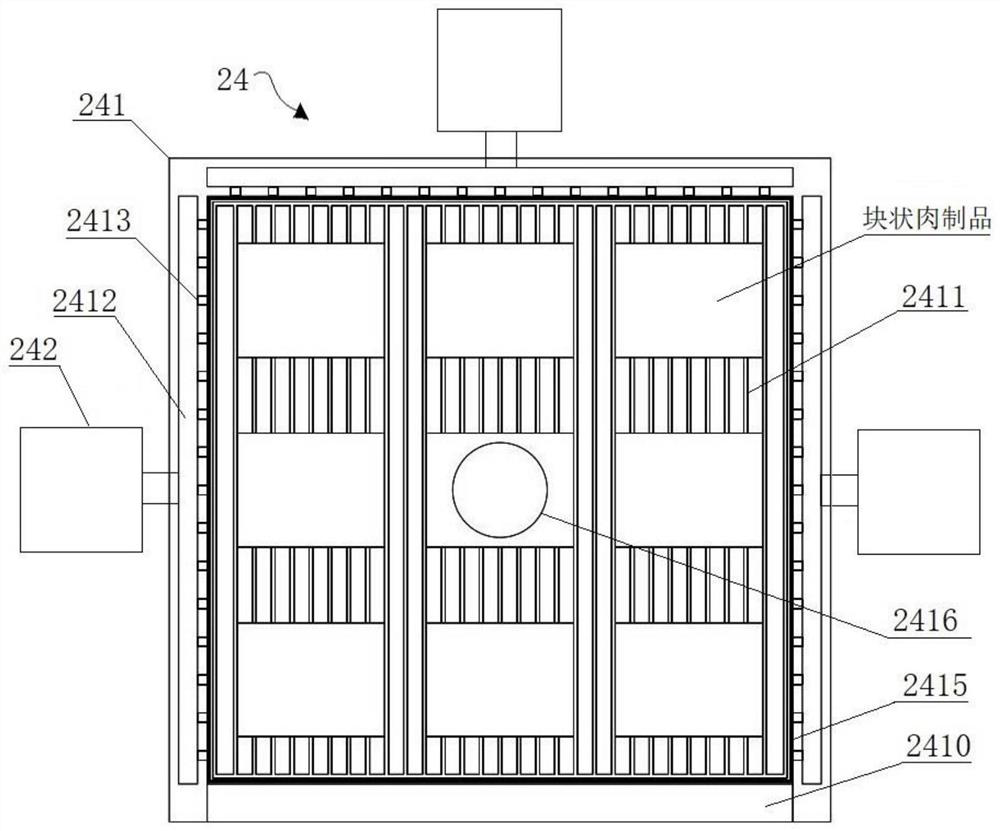

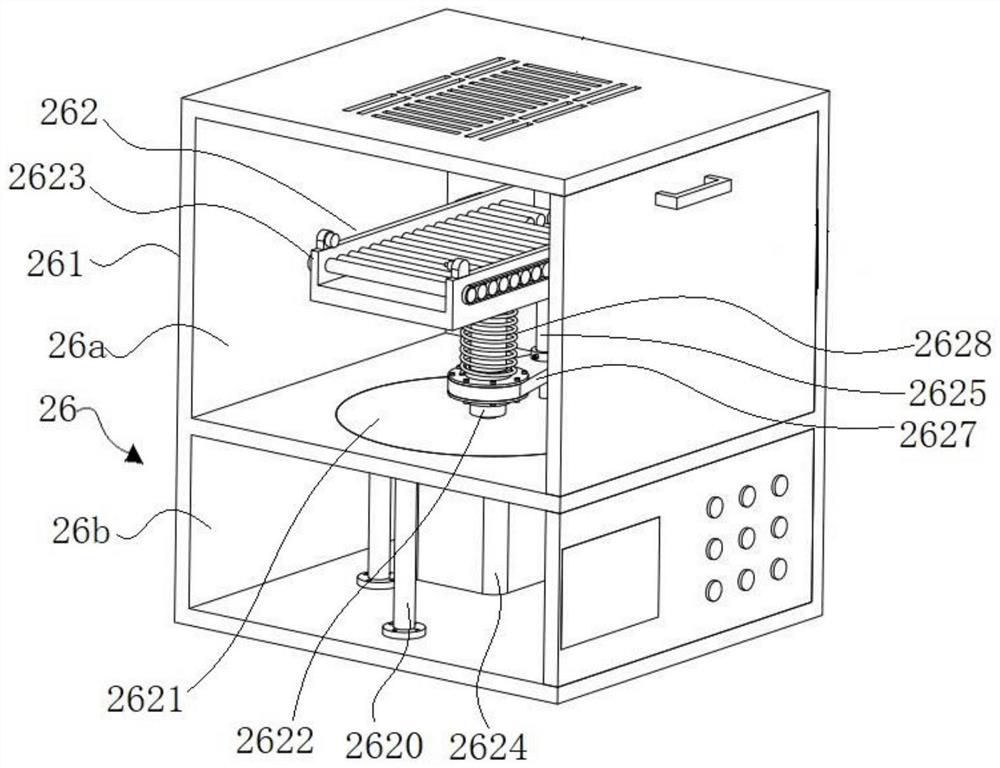

[0036] as attached figure 1 As shown, a meat product aseptic processing workshop system includes an aseptic processing workshop 1 and a block meat product processing line 2 located in the aseptic processing workshop 1; the block meat product processing line 2 includes sequentially arranged in the assembly line 20 on the primary cleaning device 21, disinfection and sterilization device 22, secondary cleaning device 23, moisture reduction air-drying equipment 24, seasoning pickling device 25, baking equipment 26, rapid cooling equipment 27 and packaging device 28; the primary cleaning device 21 Clean the massive meat products once to remove blood on the surface of the massive meat products; the disinfection and sterilization device 22 sterilizes the massive meat products; the secondary cleaning device 23 performs secondary cleaning on the massive meat products to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com