Turn-over system for nursing ward

A ward and hospital bed technology, applied in the field of nursing, can solve the problems of inability to control the turning angle, unable to use the patient to turn over, insufficient safety, etc., and achieve the effects of low configuration cost, space saving and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

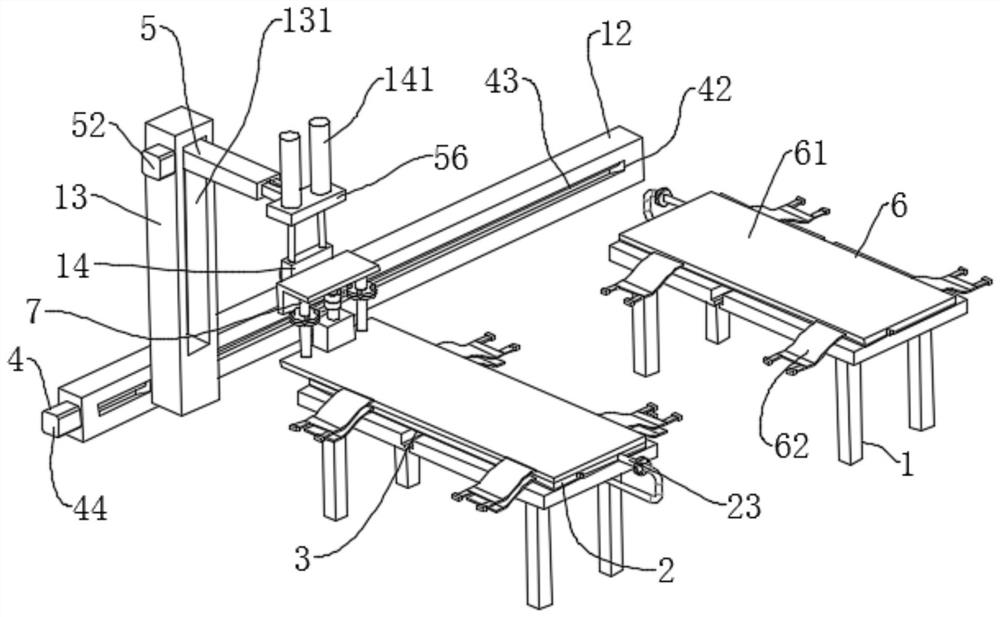

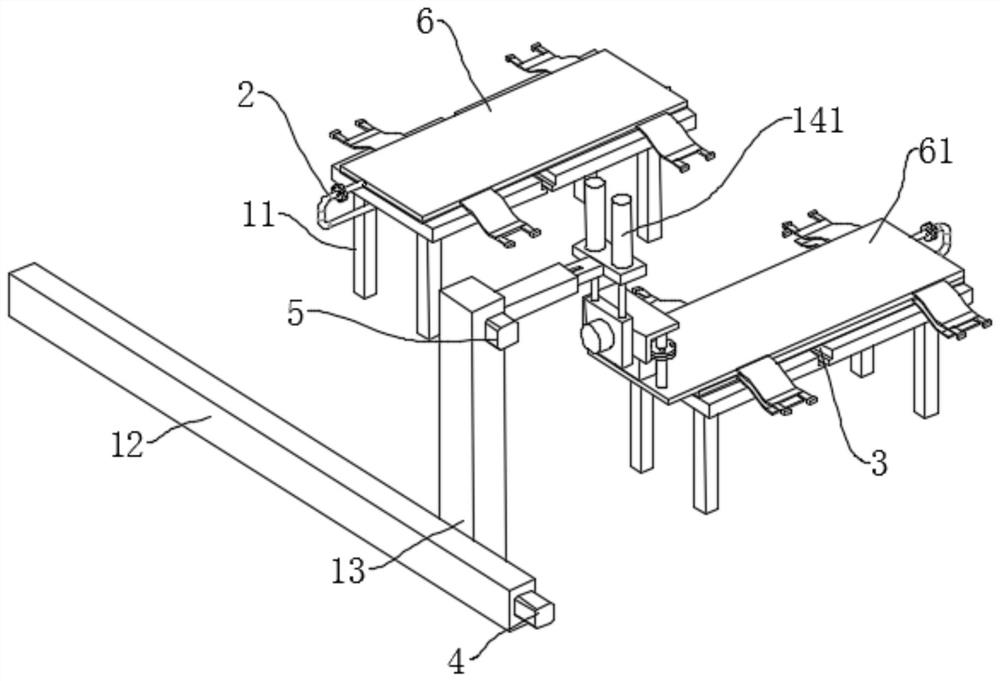

[0057] refer to figure 1 and figure 2 , a nursing ward turning system and its technology, mainly including the following parts:

[0058] Several hospital beds 11 located in the ward;

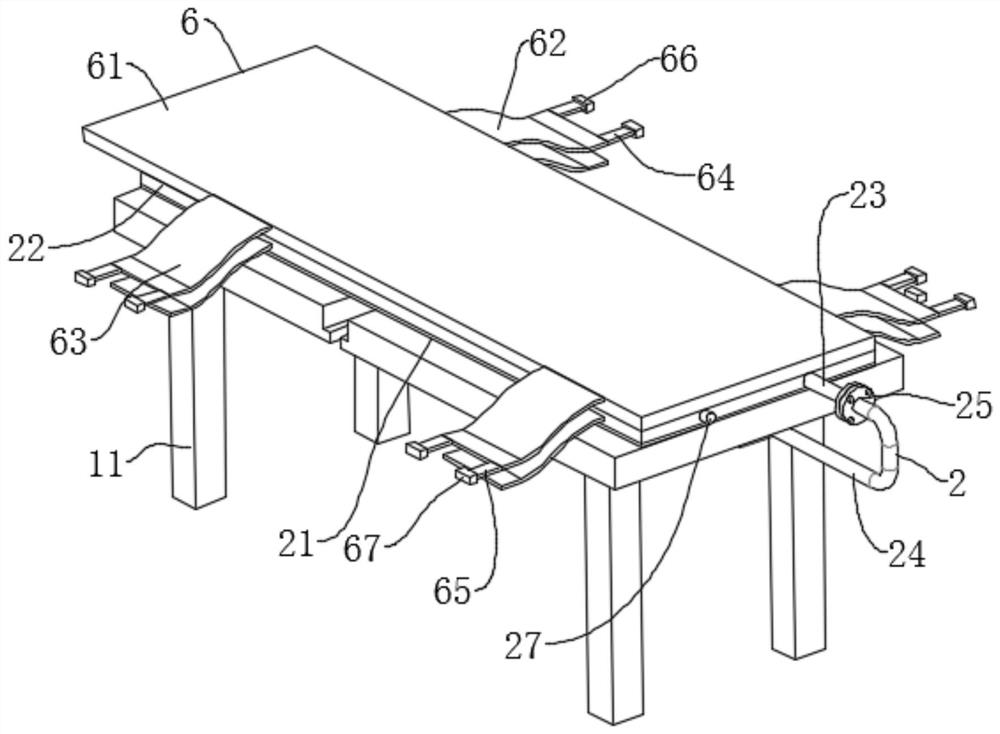

[0059] The air bag 22 assembly 2 arranged on the top surface of the hospital bed 11;

[0060] Two sets of locking assemblies 3 for fixing the airbag 22 assembly 2 above the hospital bed 11;

[0061] The support seat 12 fixed on the side wall of the ward;

[0062] Horizontally slide the support column 13 connected to one side of the support seat 12;

[0063] The first power assembly 4 for driving the support column 13 to slide horizontally;

[0064] An insertion groove 131 provided on the side of the support column 13 close to the hospital bed 11;

[0065] The boom assembly 5 that can be rotated in and out of the insertion slot 131 and can be telescopic;

[0066] Slidingly connected to the support seat 14 at one end of the boom assembly 5;

[0067] The first hydraulic cylinder 141 fixed ...

Embodiment 2

[0082] The difference with Example 1 is:

[0083] The surface of the carrier plate 61 is also coated with an antifouling coating, wherein the antifouling coating is prepared by the following method:

[0084] Take the following raw materials for each component by weight: 50 parts of PPS resin, 40 parts of methyl methacrylate, 40 parts of trifluoroethyl methacrylate, 30 parts of trimethylchlorosilane, 30 parts of ethyl acetate, epoxy 20 parts of resin emulsion, 10 parts of mixed capsaicin, 10 parts of silane coupling agent, 10 parts of cuprous oxide nanoparticles;

[0085] S1. Prepare anti-fouling coating pre-preparation solution; stir PPS resin, methyl methacrylate, and trifluoroethyl methacrylate evenly, add to the reaction kettle and heat to 210°C, and then keep warm for 30 minutes;

[0086] S2. Prepare antifouling coating solution: add trimethylchlorosilane, ethyl acetate, epoxy resin emulsion, mixed capsaicin, silane coupling agent, cuprous oxide nanometer to the antifouli...

Embodiment 3

[0090] The difference from Example 2 lies in the preparation method of the antifouling coating on the surface of the carrier plate 61, wherein the preparation method of the antifouling coating is as follows:

[0091] Take the following components by weight for later use: 53 parts of PPS resin, 43 parts of methyl methacrylate, 42 parts of trifluoroethyl methacrylate, 32 parts of trimethylchlorosilane, 33 parts of ethyl acetate, epoxy 20 parts of resin emulsion, 10 parts of mixed capsaicin, 10 parts of silane coupling agent, 10 parts of cuprous oxide nanoparticles;

[0092] S1. Prepare anti-fouling coating pre-preparation solution; stir PPS resin, methyl methacrylate, and trifluoroethyl methacrylate evenly, add to the reaction kettle and heat to 214°C, and then keep warm for 30 minutes;

[0093] S2. Prepare antifouling coating solution: add trimethylchlorosilane, ethyl acetate, epoxy resin emulsion, mixed capsaicin, silane coupling agent, cuprous oxide nanometer to the antifouli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com