Enhanced water photolysis hydrogen production device

An enhanced technology for hydrogen production by photolysis of water, applied in the field of hydrogen production, can solve the problems of low hydrogen production efficiency and low light utilization efficiency, achieve high hydrogen production efficiency, high light utilization rate, and improve the ability of photolysis of water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

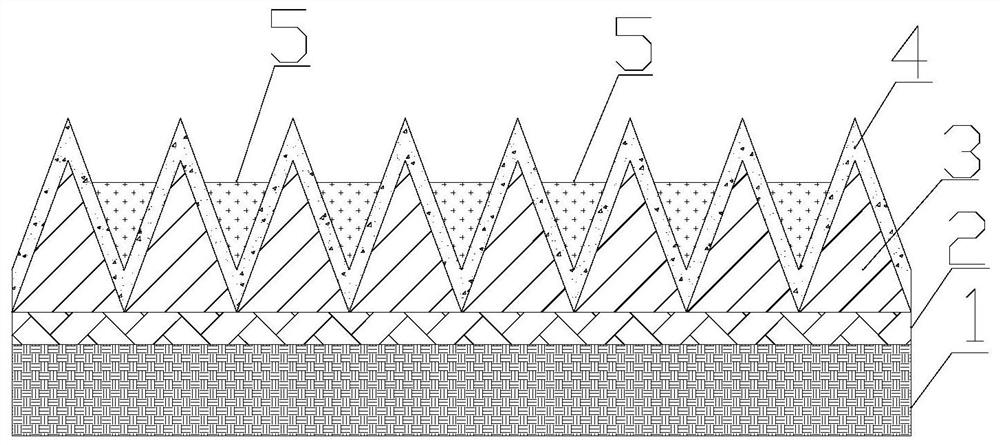

[0021] The invention provides an enhanced photolysis water hydrogen production device. Such as figure 1 As shown, the enhanced photo-splitting water hydrogen production device includes a base layer 1 , a reflective layer 2 , a silicon dioxide part 3 , a thin film layer 4 , and a first titanium dioxide part 5 . The reflective layer 2 is placed on the base layer 1 . The material of reflective layer 2 is noble metal, which is used to reflect from figure 1 Light incident from above. The cross section of the silica portion 3 is tapered. Silicon dioxide portions 3 are placed periodically on the reflective layer 2 . The silicon dioxide part 3 can be strip-shaped, so that the strip-shaped silicon dioxide part 3 is periodically placed on the reflective layer 2 according to a certain direction. The silicon dioxide part 3 can also be an independent cone shape, so that the independent silicon dioxide part 3 is periodically placed on the reflective layer 2 in two directions. The thin...

Embodiment 2

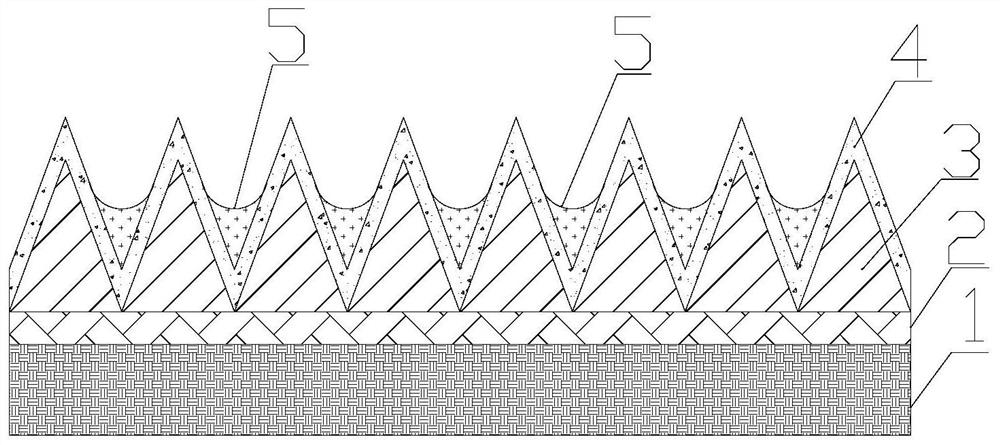

[0027] On the basis of Example 1, such as figure 2 As shown, the upper surface of the first titanium dioxide portion 5 is concave. That is to say, near the silicon dioxide part 3, the first titanium dioxide part 5 is high; at a place away from the silicon dioxide part 3, the first titanium dioxide part 5 is low. In this way, the first titanium dioxide part 5 has more surface area, and the contact area with water is larger, and it is easier to photolyze water, and the bubbles generated by photolyzed water are also easier to desorb from the titanium dioxide material, thereby further improving the optical efficiency. Hydrolysis ability. On the other hand, near the silicon dioxide part 3, the titanium dioxide material is relatively thin, and under the action of incident light, a strong electric field region can be formed to enhance the interaction between light and the titanium dioxide material, and the titanium dioxide material will generate more photogenerated electrons and ph...

Embodiment 3

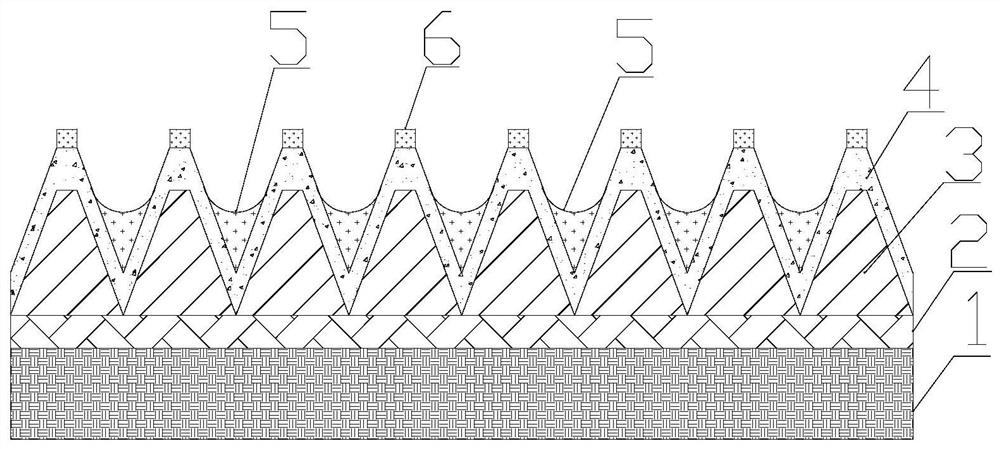

[0029] On the basis of Example 2, the inclination angles on both sides of the silicon dioxide portion 3 are the same. The inclination angles of the two sides of adjacent silicon dioxide portions 3 are different. That is to say, for one silicon dioxide part 3 , the inclination angles of the two sides of the tapered structure are the same, which is equivalent to an isosceles structure. However, for adjacent silicon dioxide portions 3 , the inclination angles of the two sides of the tapered structure are different. Although the cross-section of each silicon dioxide part 3 is an isosceles structure, the shapes of the cross-sections of adjacent silicon dioxide parts 3 are different: the base angles of the isosceles structures are different. In this way, for the groove formed by the adjacent silicon dioxide part 3, the two sides of the groove are asymmetrical, and the situation of the bubbles being precipitated from both sides of the groove is also asymmetrical, and the bubbles are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com