LED epitaxial structure and application thereof, light-emitting diode comprising LED epitaxial structure and preparation method of LED epitaxial structure

A technology of light-emitting diodes and epitaxial structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of blocking photon overflow and low brightness, and achieve the effects of increasing horizontal expansion ability, improving crystal quality, and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

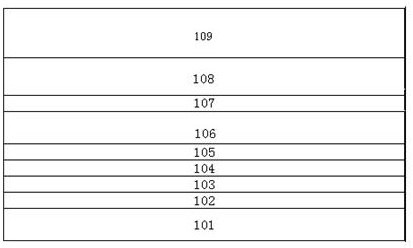

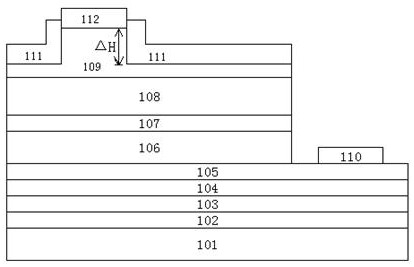

[0034] This implementation mode provides an LED epitaxial structure, such as figure 1As shown, it includes a patterned sapphire substrate 101, an AlN nucleation layer 102, a buffer layer 103, an undoped GaN layer 104, a Si-doped n-type GaN layer 105, a multi-quantum well light-emitting layer 106, and An electron blocking layer 107 , a Mg-doped p-type GaN layer 108 and a p-type contact layer 109 .

[0035] The material of the electron blocking layer 107 is p-type Al doped with Mg 0.2 In 0.1 Ga 0.7 N layer, thickness is 30nm; Mg doping concentration is 2E+20Atom / cm 3 .

[0036] The material of the Mg-doped p-type GaN layer 108 is a Mg-doped p-type Al0.1Ga0.9N layer with a thickness of 30nm; the Mg doping concentration is 6E+19Atom / cm 3 .

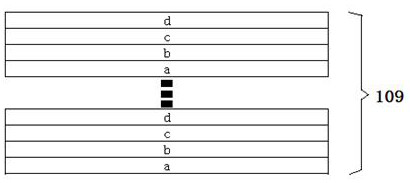

[0037] Such as figure 2 As shown, the above-mentioned p-type contact layer 109 is four p-type GaN / p-type In layers grown periodically from bottom to top 0.2 Ga 0.8 N / p type Al 0.2 In 0.2 Ga 0.6 N / MgN superlattice layer, the thickn...

Embodiment approach 2

[0054] This embodiment is roughly the same as Embodiment 1, except that the p-type contact layer 109 in this embodiment is four p-type GaN / p-type In layers grown periodically from bottom to top. 0.1 Ga 0.9 N / p type Al 0.2 In 0.1 Ga 0.7 N / MgN superlattice layer, wherein the thickness of p-type GaN layer a is 2nm; p-type In 0.1 Ga 0.9 The thickness of N layer b is 2nm; p-type Al 0.2 In 0.1 Ga 0.7 The thickness of the N layer c is 2 nm; the thickness of the MgN layer d is 1 nm.

[0055] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

Embodiment approach 3

[0057] This embodiment is roughly the same as Embodiment 1, except that the p-type contact layer 109 in this embodiment is four p-type GaN / p-type In layers grown periodically from bottom to top. 0.3 Ga 0.7 N / p type Al 0.2 In 0.3 Ga 0.5 N / MgN superlattice layer, wherein the thickness of p-type GaN layer a is 2nm; p-type In 0.3 Ga 0.7 The thickness of N layer b is 2nm; p-type Al 0.2 In 0.3 Ga 0.5 The thickness of the N layer c is 2 nm; the thickness of the MgN layer d is 1 nm.

[0058] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com