Dual-blade sleeve electrolytic processing device and processing method thereof

A processing device and double-blade technology, applied in the direction of electric processing equipment, electrochemical processing equipment, accessory devices, etc., can solve the problems of low processing efficiency, improve processing efficiency and precision, avoid stray corrosion, and prevent stray corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the operation steps of workpiece processing, further illustrate the working method of the present invention:

[0024] (a) Start the heating system, and when the temperature of the electrolyte is heated to 30°C, start the constant temperature system;

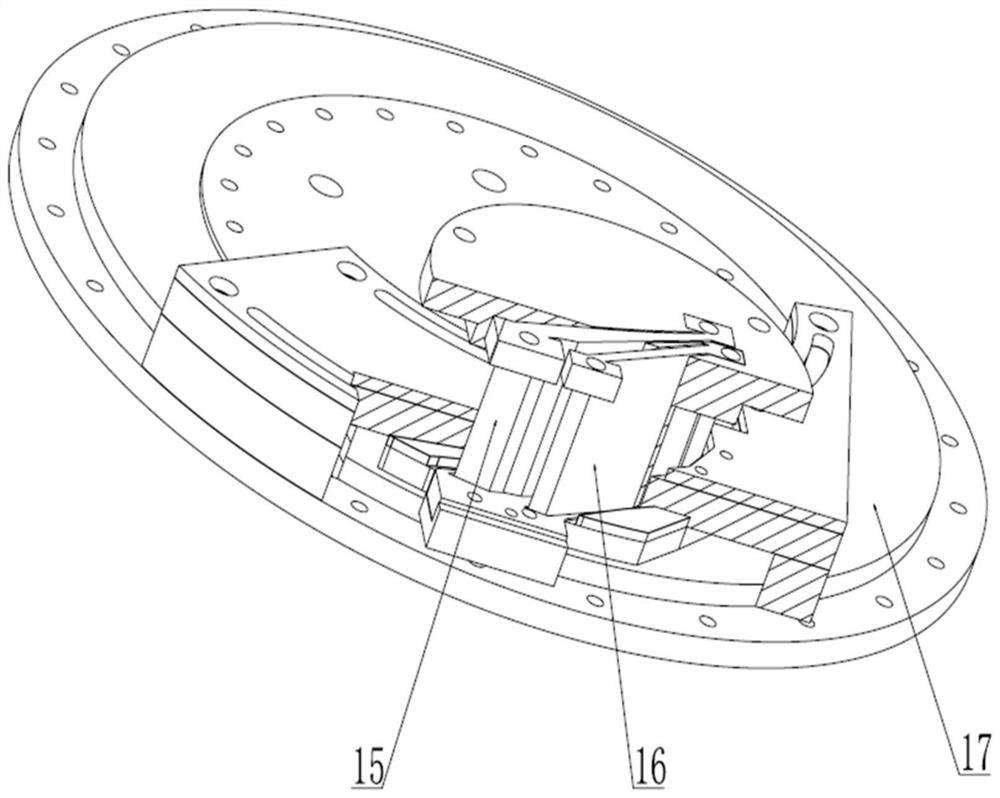

[0025] (b) Start the electrolyte circulation system, and pass the electrolyte through the liquid inlet;

[0026] (c) Activate the DC power source to energize the tool cathode and workpiece anode;

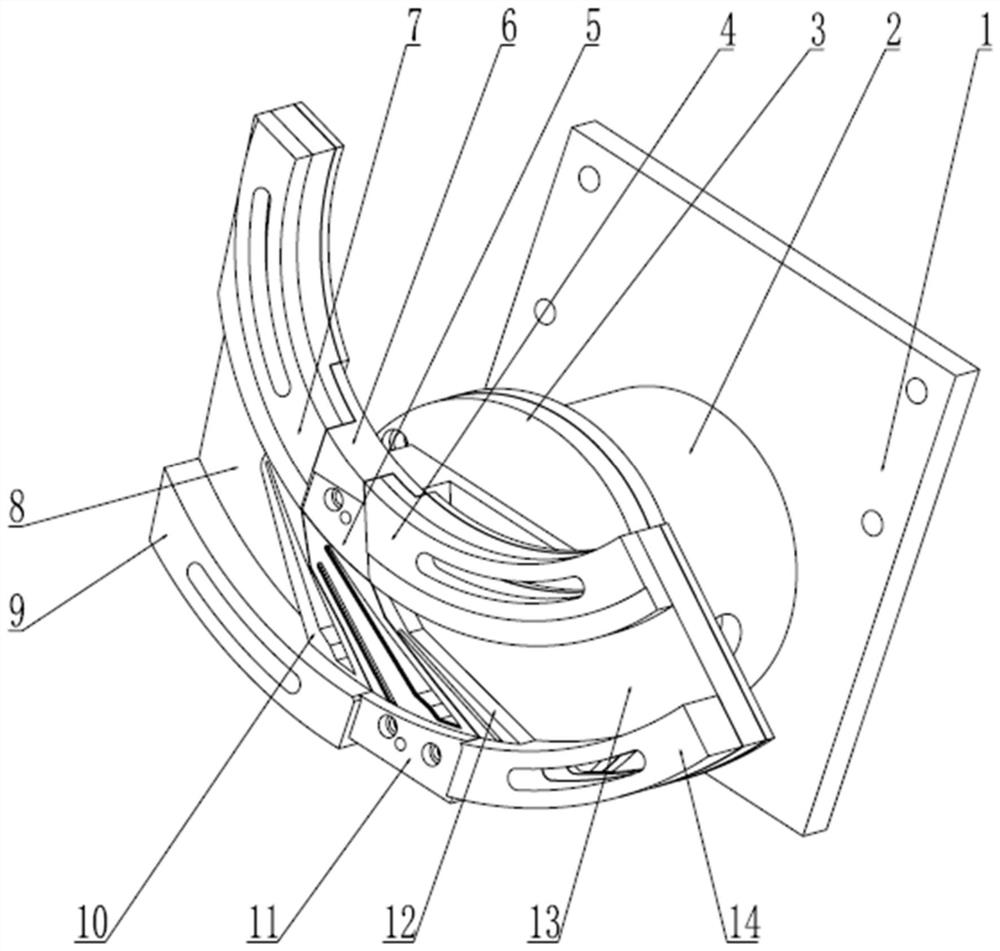

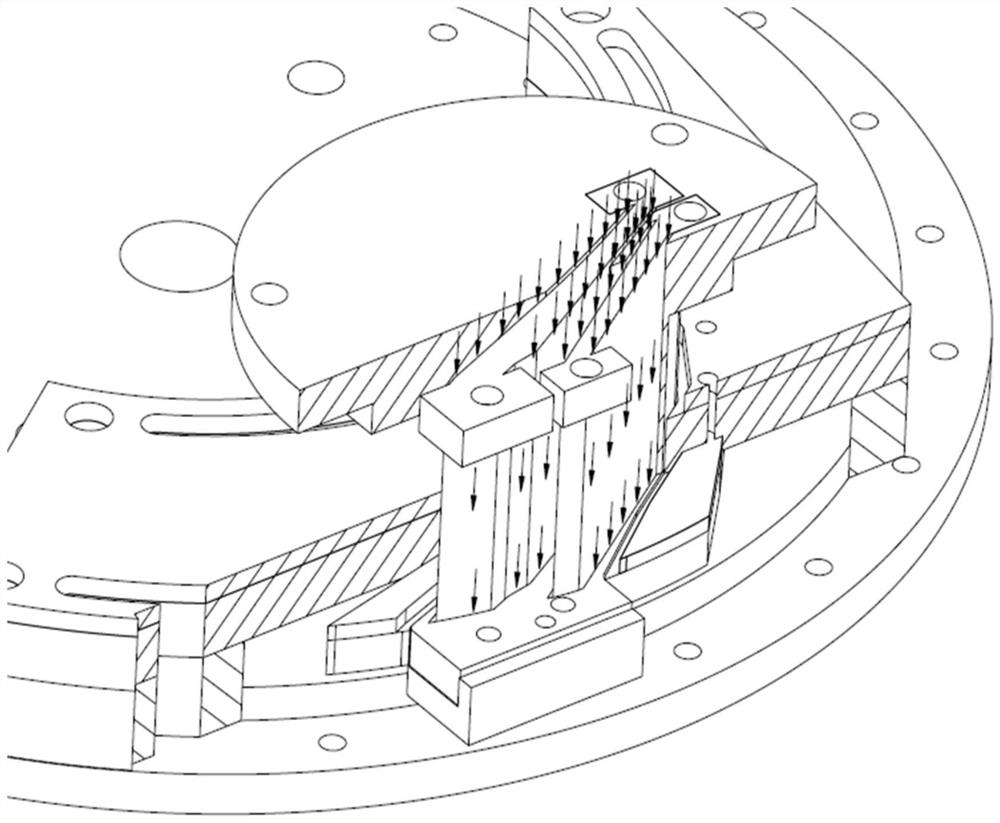

[0027] (d) Start the CNC machine tool operation program, the anode workpiece is fed along the axis of the workpiece, and in the electrolyte environment, the tool cathode gradually removes the anode workpiece material through electrolytic corrosion. With the axial feed of the workpiece, the dual-blade contour machining edge on the tool cathode can produce two blades with different contours at one time.

[0028] (e) Rotate the workpiece at a certain angle, feed the workpiece again, and process an adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com