BOPP film for in-film labeling and preparation method thereof

A labeling and film technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of poor thermal stability of films, difficult and easy adhesion of ink, high static electricity of films, etc., to reduce thermal shrinkage rate and prevent film adhesion , the effect of strong conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

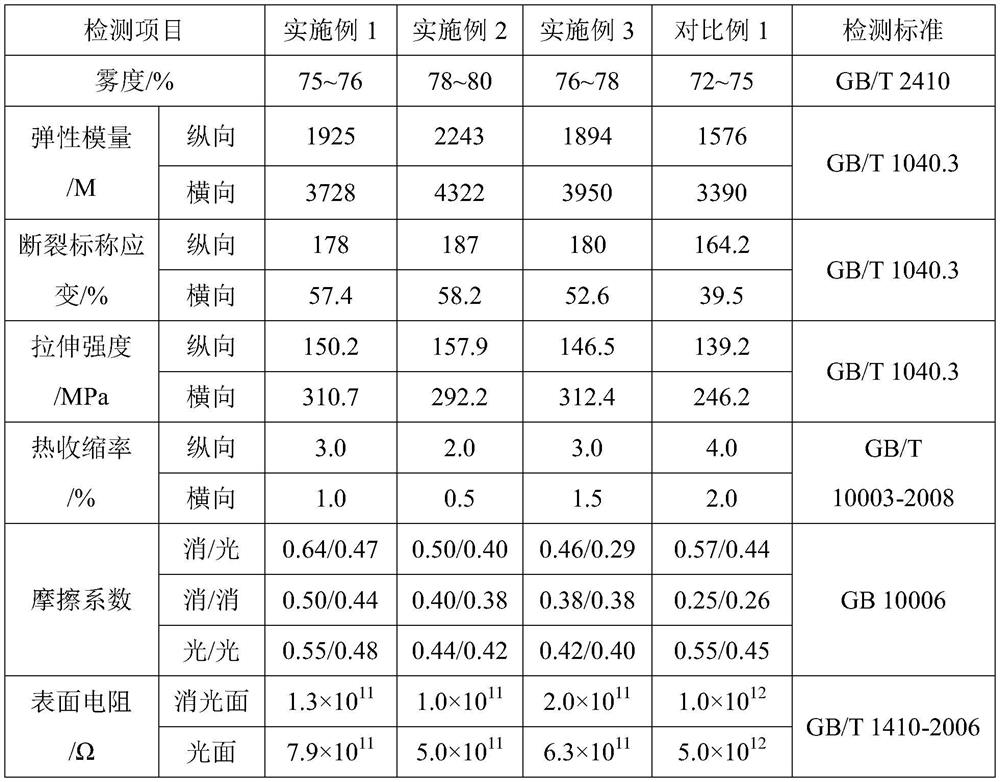

Examples

Embodiment 1

[0027] A BOPP film for in-film labeling proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer, and the thicknesses of each layer are 1.0 μm, 45.5 μm, and 3.5 μm in sequence.

[0028] The upper surface layer is an anti-adhesive layer, and its material is composed of the following components by weight: 95% of polypropylene copolymer, 5% of anti-adhesive masterbatch;

[0029] Among them, the anti-adhesive masterbatch is homopolypropylene loaded with spherical nano-silica particles, the weight ratio of spherical nano-silica particles to homo-polypropylene is 4:96, and the particle size of spherical nano-silica particles is 2μm, the melt index of homopolypropylene is 2.5g / 10min (230℃ / 2.16kg);

[0030] The melt index of the copolymerized polypropylene is 3.0g / 10min (230°C / 2.16kg).

[0031] The core layer is a polypropylene layer, and its material is composed of the following components by weight: homopolypropylene 90%, antis...

Embodiment 2

[0040] A BOPP film for in-film labeling proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer, and the thicknesses of each layer are 1.2 μm, 44.8 μm, and 4.0 μm in sequence.

[0041] The upper surface layer is an anti-adhesive layer, and its material is composed of the following components by weight: 96% of polypropylene copolymer, 4% of anti-adhesive masterbatch;

[0042] Among them, the anti-adhesive masterbatch is homopolypropylene loaded with spherical nano-silica particles, the weight ratio of spherical nano-silica particles to homo-polypropylene is 5:95, and the particle size of spherical nano-silica particles is 4μm, the melt index of homopolypropylene is 3.0g / 10min (230℃ / 2.16kg);

[0043] The melt index of the copolymerized polypropylene is 3.2g / 10min at 230°C / 2.16kg.

[0044]The core layer is a polypropylene layer, and its material is composed of the following components by weight: homopolypropylene 92%, antis...

Embodiment 3

[0053] A BOPP film for in-film labeling proposed by the present invention is composed of an upper surface layer, a core layer and a lower surface layer, and the thicknesses of each layer are 1.5 μm, 44.5 μm, and 4.0 μm in sequence.

[0054] The upper surface layer is an anti-adhesive layer, and its material is composed of the following components by weight: 97% of polypropylene copolymer, 3% of anti-adhesive masterbatch;

[0055] Among them, the anti-adhesive masterbatch is homopolypropylene loaded with spherical nano-silica particles, the weight ratio of spherical nano-silica particles to homo-polypropylene is 6:94, and the particle size of spherical nano-silica particles is 5μm, the melt index of terpolymer is 3.2g / 10min(230℃ / 2.16kg);

[0056] The melt index of the copolymerized polypropylene is 3.5g / 10min at 230°C / 2.16kg.

[0057] The core layer is a polypropylene layer, and its material is composed of the following components by weight: homopolypropylene 96%, antistatic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com