Graphene fiber

A graphene fiber, graphene technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of affecting the fiber transportation and collection process, the collection of unbreakable fiber filaments, and the reduction of graphene spinning efficiency. The ability to stick, prevent slipping, prevent confusion and knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

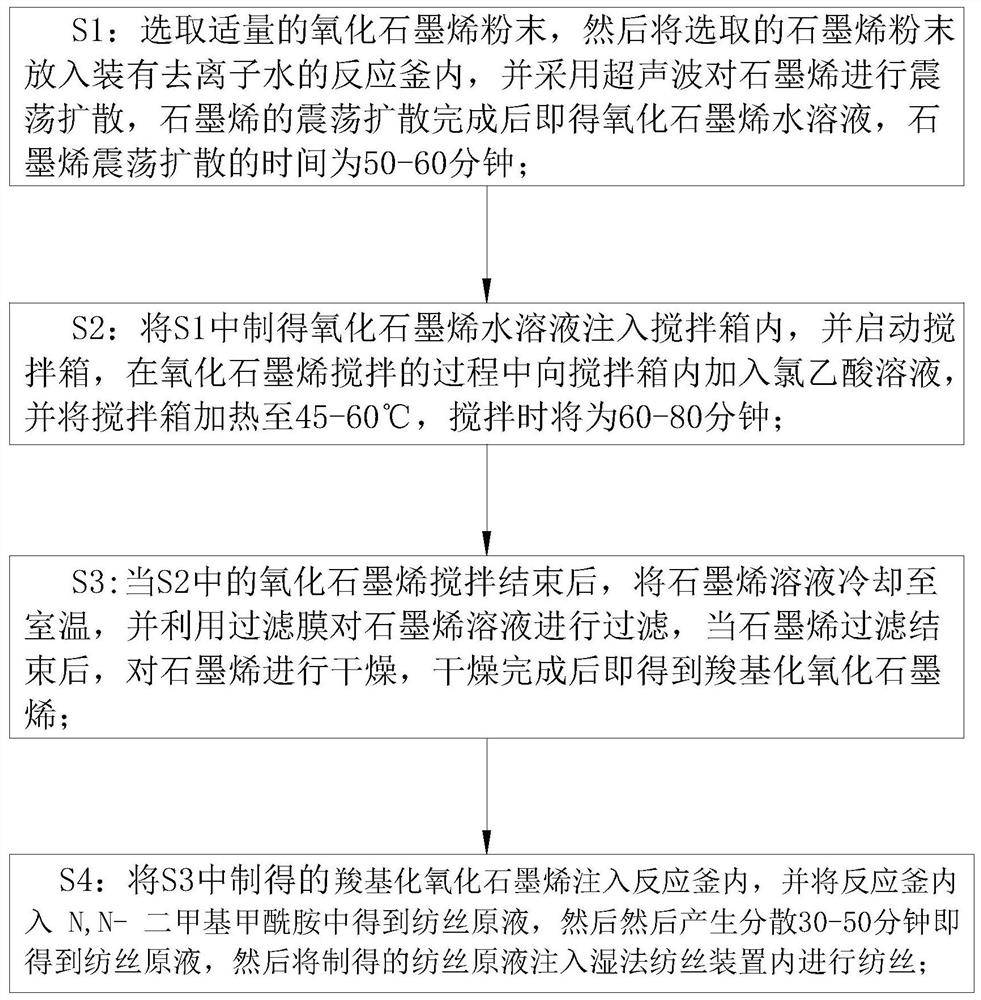

Method used

Image

Examples

Embodiment approach

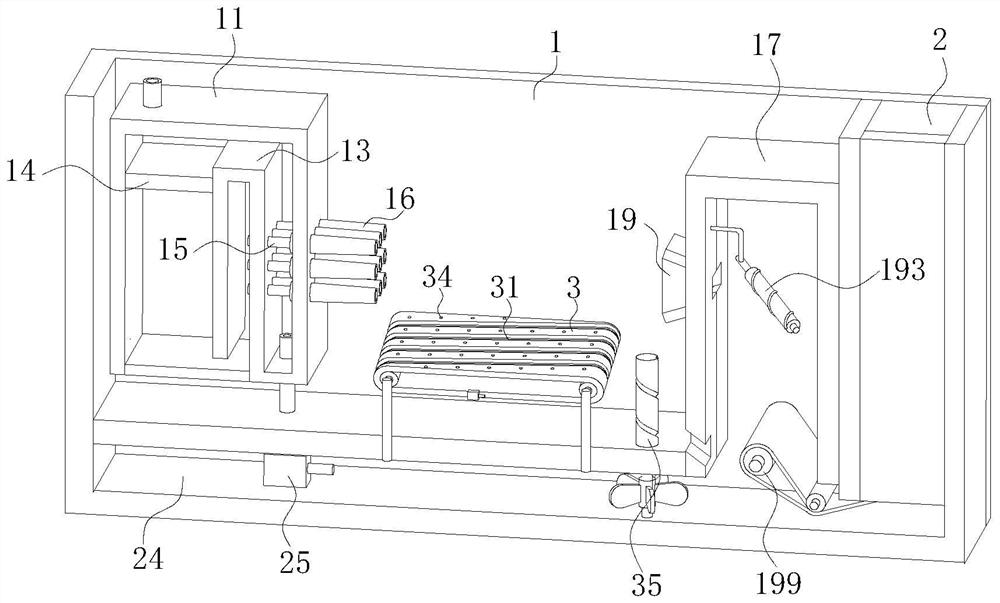

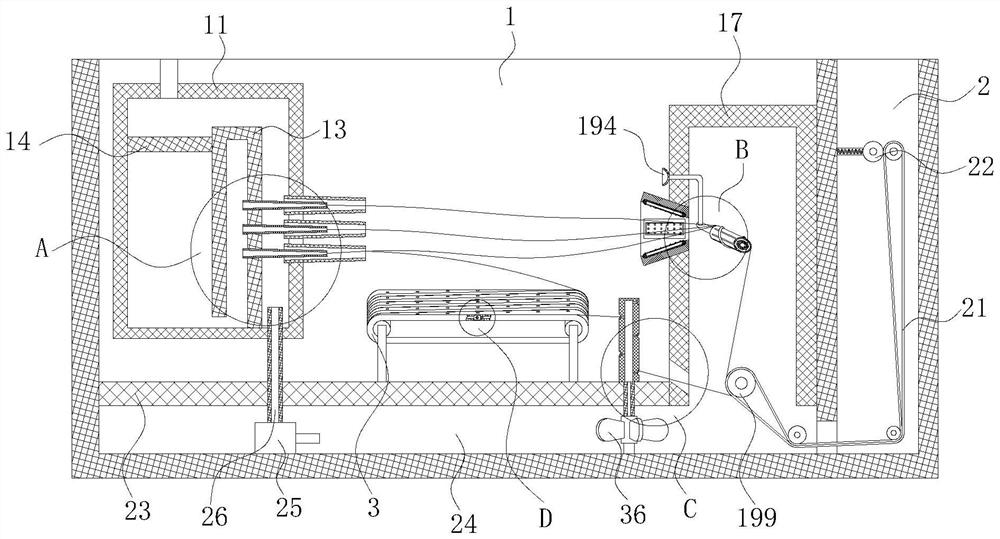

[0048] As an embodiment of the present invention, the outer surface of the auxiliary roller 193 is fixed with a roll layer 198, and the roll layer 198 is designed to be spiral and wrapped around the auxiliary roll 193; the inner wall of the roll layer 198 is opened and closed with a roll cavity, And the volume chamber communicates with the liquid tank 195;

[0049] During work, since the outer surface of the auxiliary roller 193 is fixedly connected with the coil layer 198, and the coil layer 198 is of a spiral design, the fiber filaments wound on the auxiliary roller 193 can be wound on the auxiliary roller 193 along the coil layer 198 and slide downward. In this process, the fiber filaments can be sorted, thereby preventing the fiber filaments from falling apart and knotting. Since the volume chamber in the volume layer 198 is connected to the liquid tank 195, the coagulation liquid in the liquid tank 195 can flow into the volume layer 198 Inside, when the liquid flows into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com