Integrated brake rocker arm device of engine

A brake rocker, integrated technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of bulky structure, low reliability, complex structure, etc., and achieve simple mechanism structure, stable and reliable spring performance, and system The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

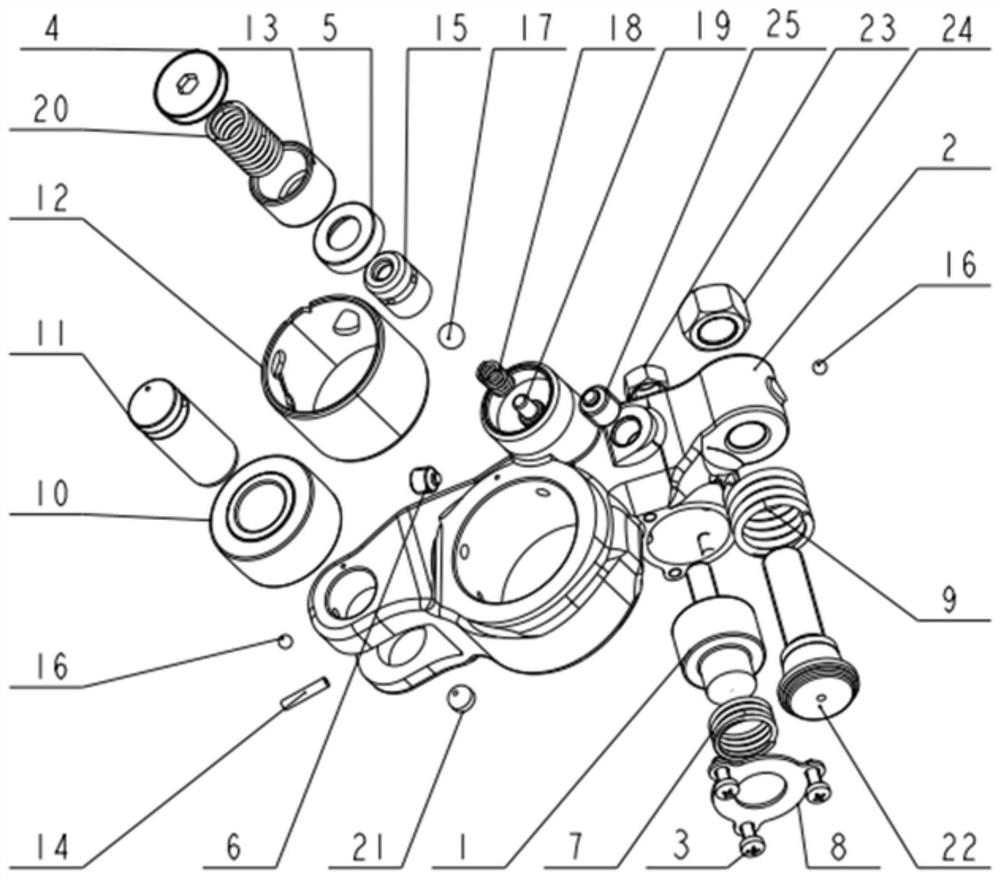

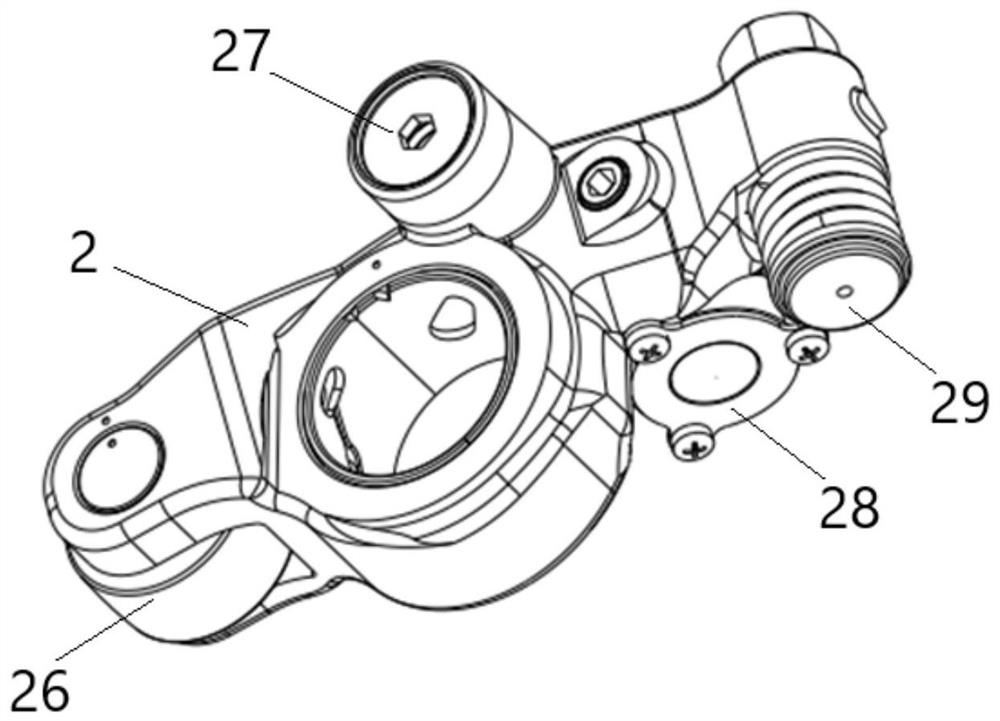

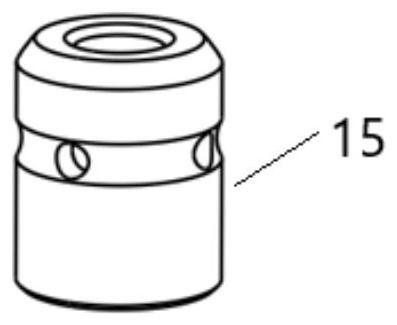

[0055] refer to figure 1 As shown, the present invention proposes an integrated braking rocker arm device for an engine, which includes a rocker arm body 2, one end of which is in contact with the exhaust cam 39 through a roller mechanism 26 hinged at the end, and an axial through hole at the other end. Exhaust gas foot 29 is arranged, and the axially arranged control chamber on the rocker arm body 2 and the axially arranged brake chamber are respectively provided with a control mechanism 27 and a braking mechanism 28 (i.e., the execution piston). With hydraulic mechanism. The control mechanism 27 includes a spool valve 15, a positioning ring 5, a cup valve 13, and a plug 4 installed in the control chamber in sequence. The spool valve 15 is provided with a ball valve seat 19, a ball valve compression spring 18 set outside the ball valve seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com