Lubricating oil supply structure

A lubricating oil and structure technology, applied in the direction of pressure lubricant, lubricating parts, valve accessories, etc., can solve the problems of increased mechanical loss, increased oil pump capacity, and worsened fuel economy, and achieve the effect of reducing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

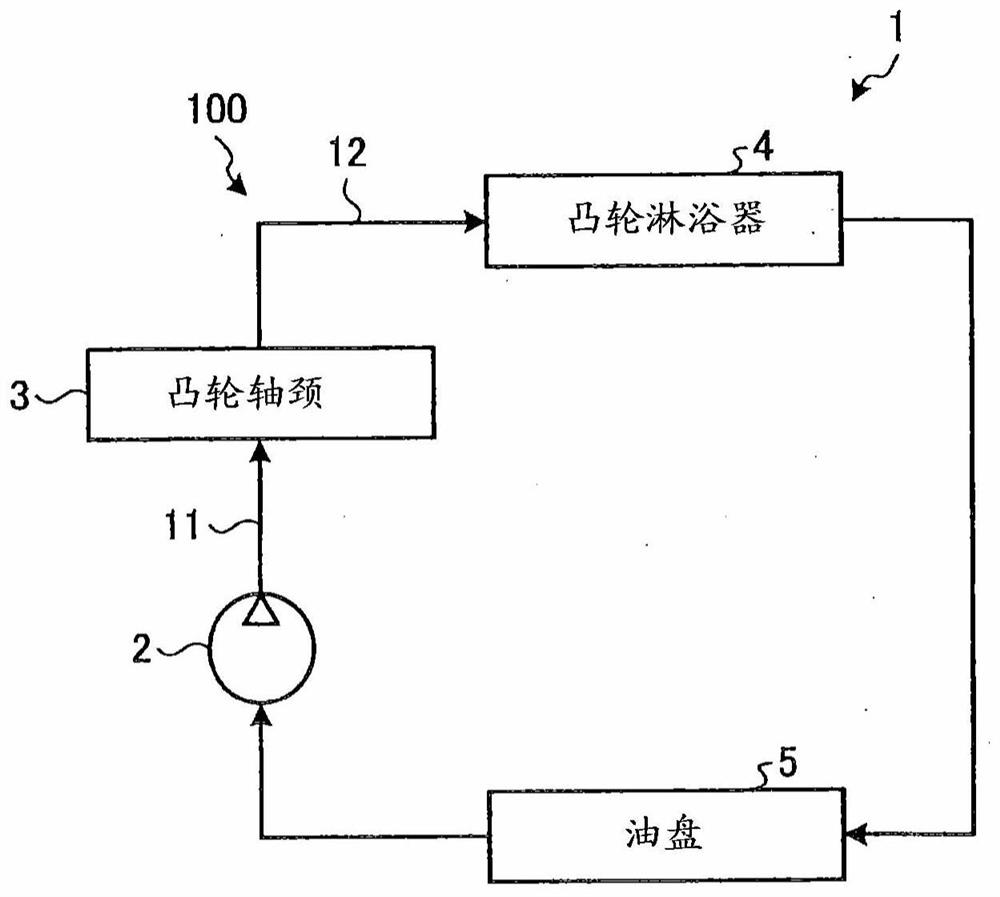

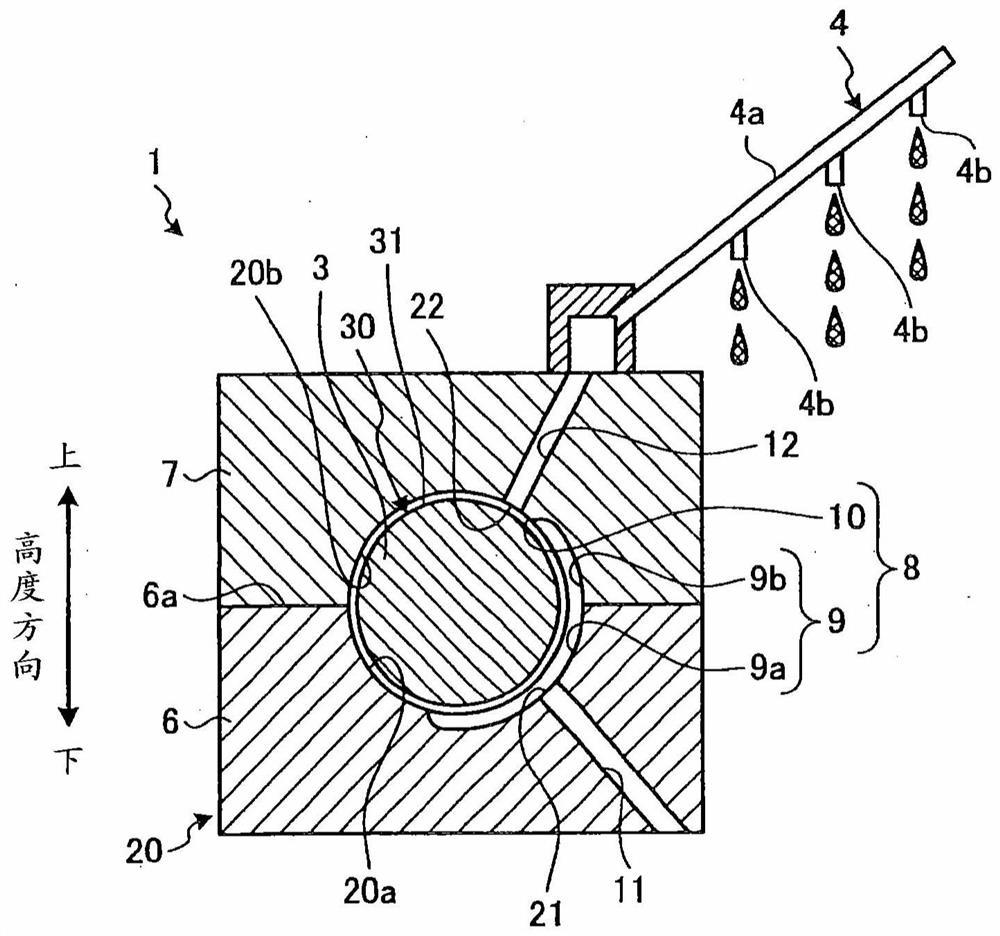

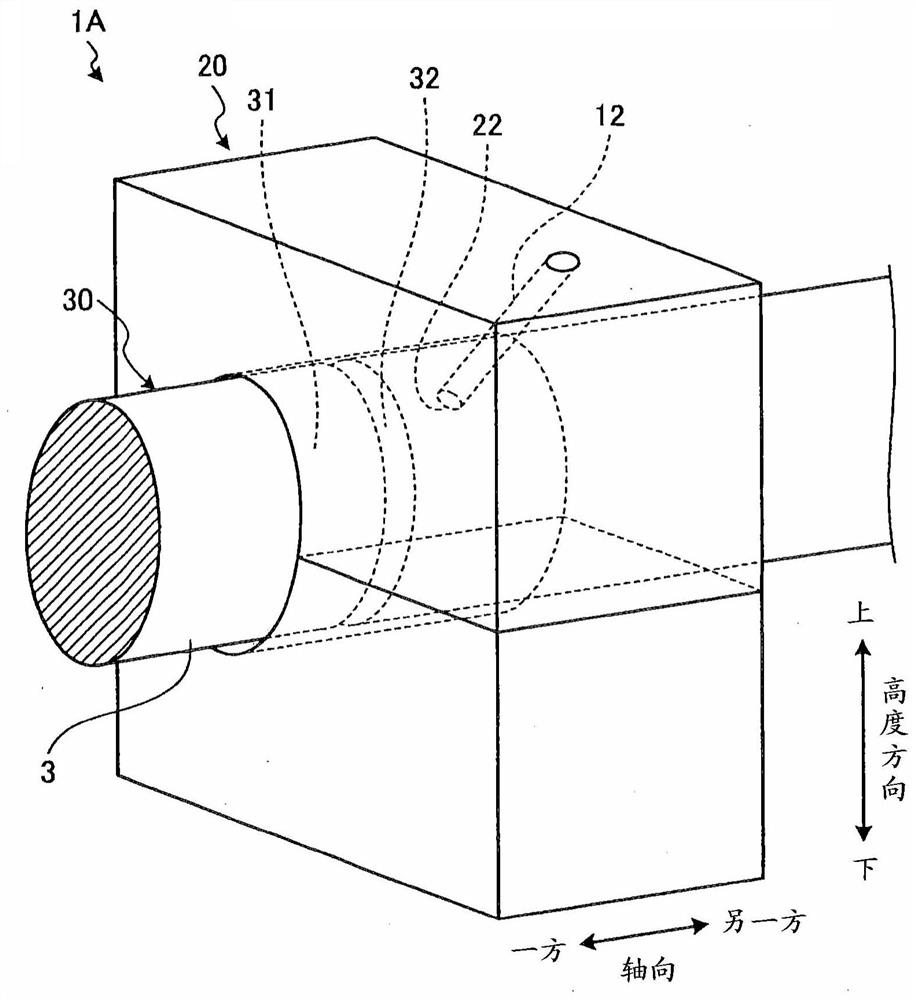

[0053] figure 1 It is a configuration diagram showing a case where the lubricating oil supply structure in the first embodiment is applied to a lubricating device for an internal combustion engine. figure 2 It is a schematic diagram which shows the schematic structure of the lubricating oil supply structure in 1st Embodiment.

[0054] The lubricating oil supply structure 1 in the first embodiment can be applied to a lubricating device 100 for an internal combustion engine. Such as figure 1 As shown, a lubricating device 100 for an internal combustion engine is a device that circulates lubricating oil using an oil pump 2 , and supplies lubricating oil to a cam journal 3 and a cam shower 4 . The supply destinations of lubricating oil include the cam journal 3 and the cam shower 4 . In this circulation path, a cam shower 4 is arranged on the downstream side of the cam journal 3 . Cam Shower 4 is where a small amount of lube is enough to get the required amount.

[0055] The...

no. 2 approach

[0082] Figure 8 It is a configuration diagram showing a case where the lubricating oil supply structure in the second embodiment is applied to a lubricating device for an internal combustion engine. Figure 9 It is a schematic diagram which shows the schematic structure of the lubricating oil supply structure in 2nd Embodiment. Figure 10 It is a schematic diagram which shows the schematic structure of the lubricating oil supply structure in 2nd Embodiment. exist Figure 10 , schematically illustrates the representation Figure 9 Cutaway view of the C-C line section. In addition, in description of 2nd Embodiment, description is abbreviate|omitted about the structure similar to 1st Embodiment mentioned above, and the code|symbol is used.

[0083] Such as Figure 8 As shown, in the lubricating device 100 of the second embodiment, the oil pumped from the oil pump 2 is supplied to the crankshaft 51 and the oil injection nozzle 52 . Destinations of lubricating oil supply inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap