Device for testing high and low temperature resistance of integrated circuit

An integrated circuit, high and low temperature resistant technology, applied in the field of integrated circuit temperature resistance detection device, can solve problems such as poor start-up of integrated circuits, impact of detection of integrated circuits to be tested, and impact on the service life of integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

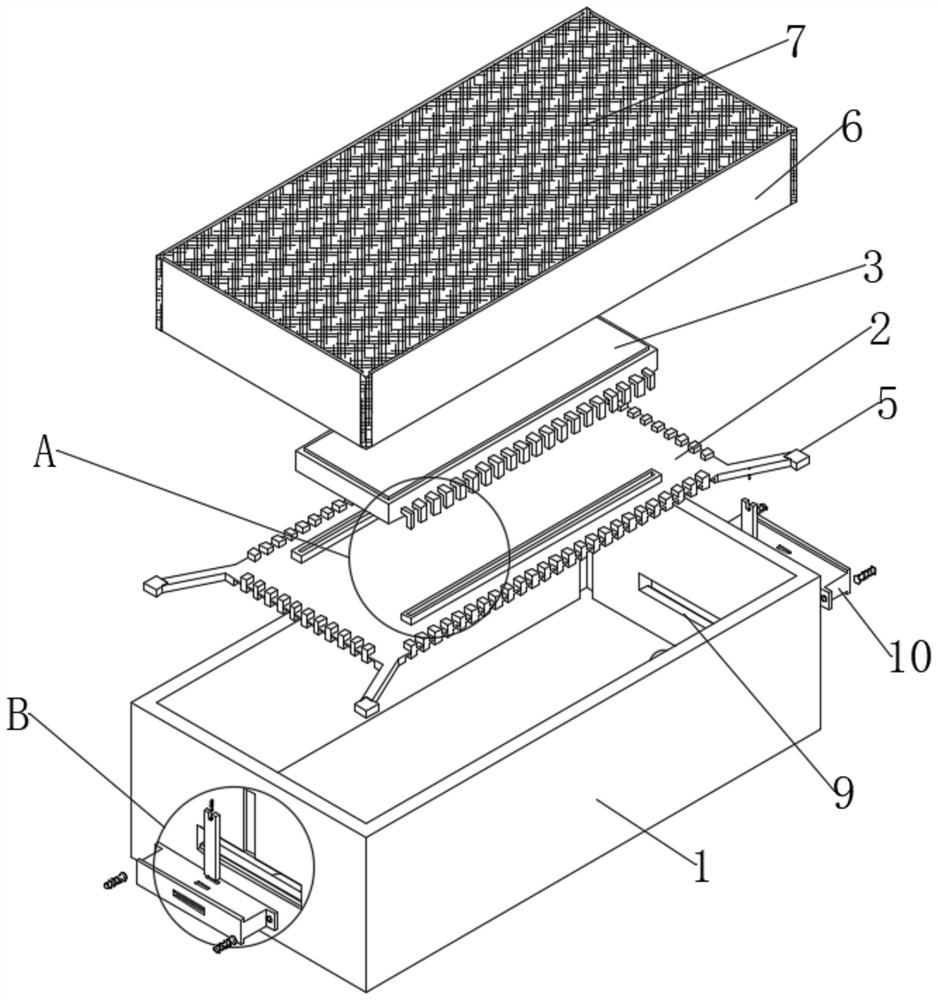

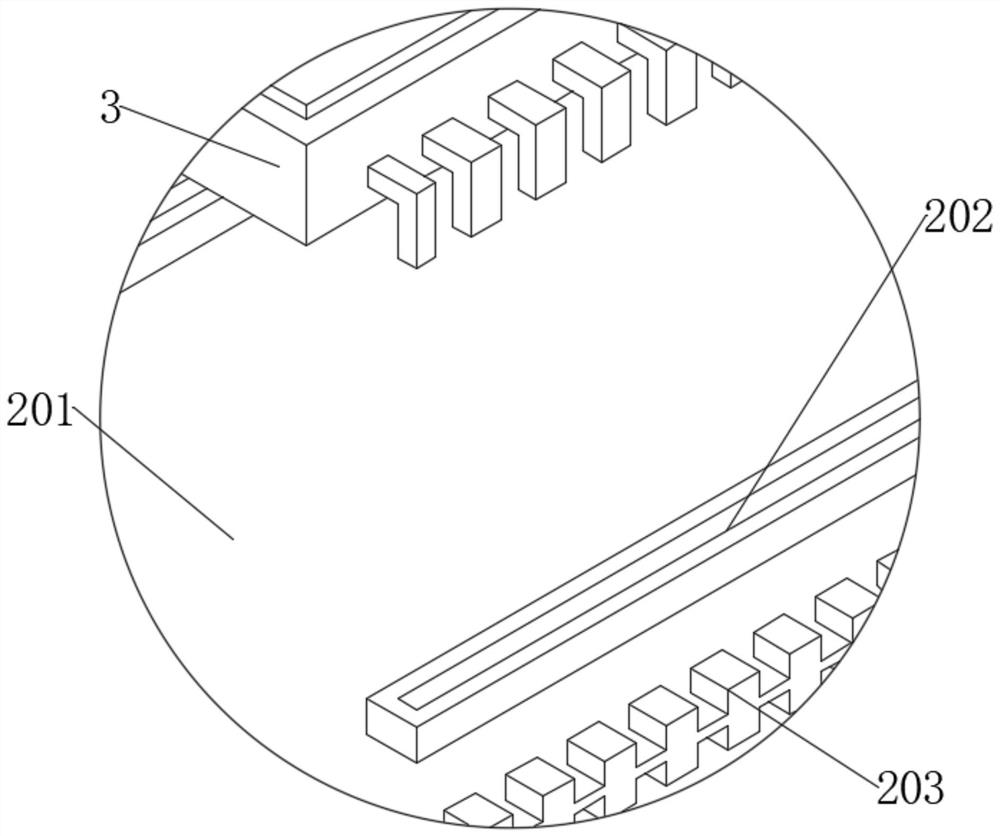

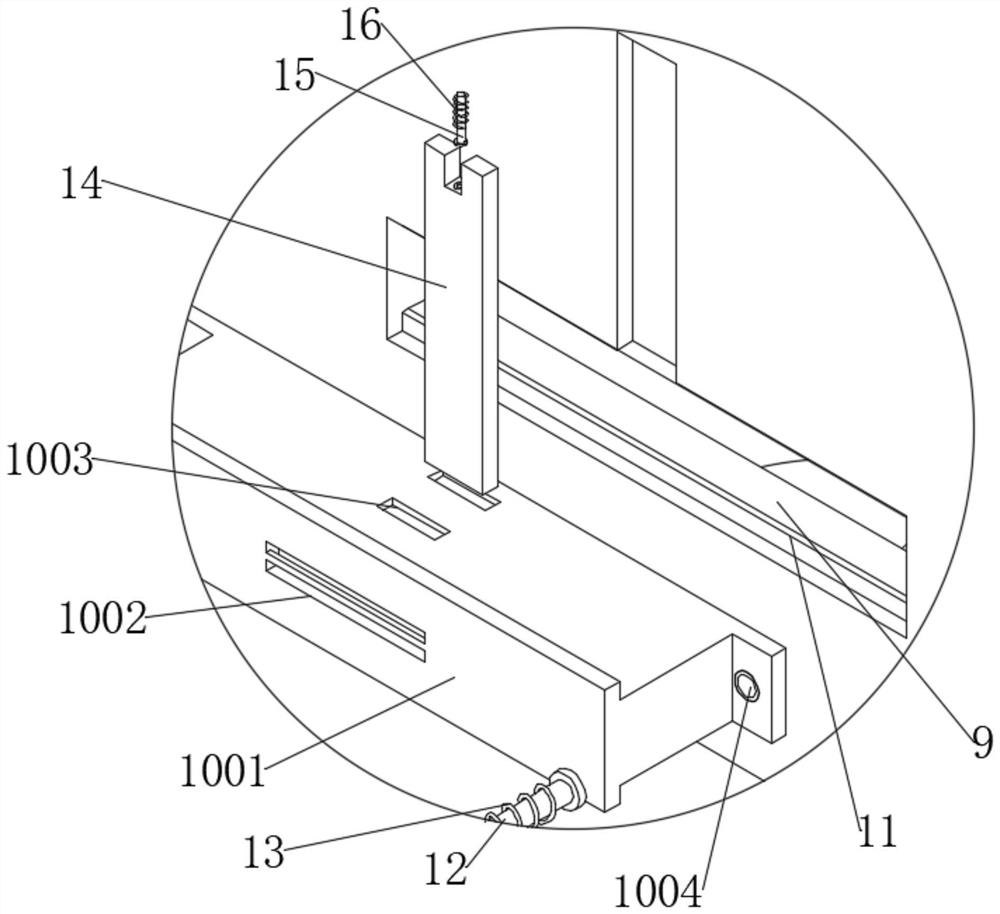

[0036] See Figure 1-2 , A device for high and low temperature resistance testing of integrated circuits, including a detection box 1. The bottom of the groove of the detection box 1 is drilled with a mounting slot, and a temperature change device 8 matching itself is fixedly connected to the mounting slot. A detection circuit board 2 that matches with itself is placed. Multiple sets of electric slide rails 4 are excavated on the side wall of the detection box 1. The multiple sets of electric slide rails 4 are all located at the corners of the detection box 1, and the detection circuit board 2 is fixed A plurality of electric sliders 5 matched with the electric slide rail 4 are connected. The detection box 1 and the detection circuit board 2 are connected by the electric slide rail 4 and the electric slider 5 to achieve a sliding connection. The upper side of the detection circuit board 2 is provided The integrated circuit main body 3, the detection circuit board 2 includes a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com