A sub-area control system and control method for a chip inserter

A technology of sub-regional control and control method, applied in general control systems, control/regulation systems, program control and other directions, can solve problems such as reducing production efficiency, reducing work efficiency, affecting equipment productivity, etc., to improve operating efficiency and improve debugging. progress, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

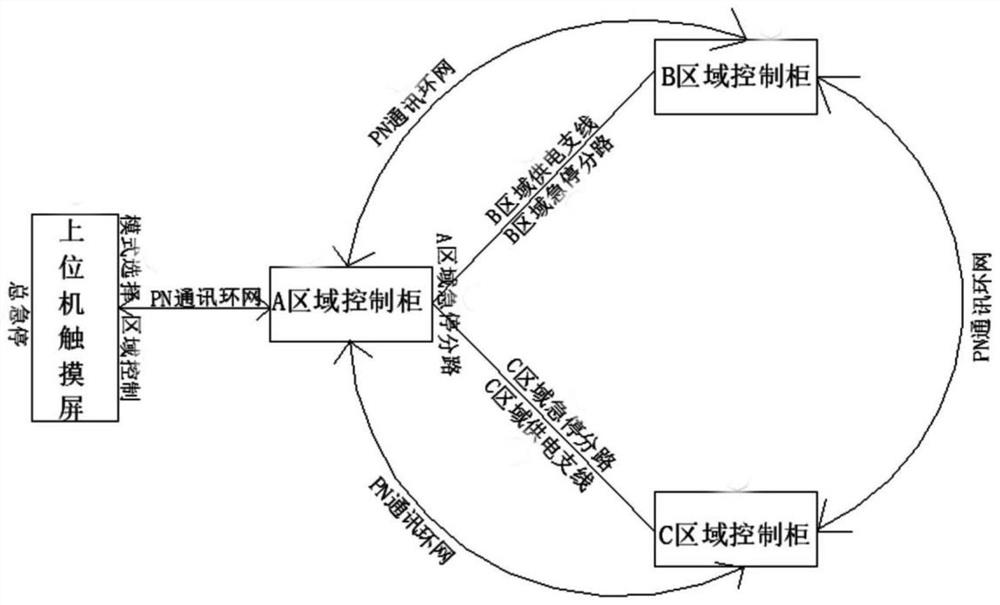

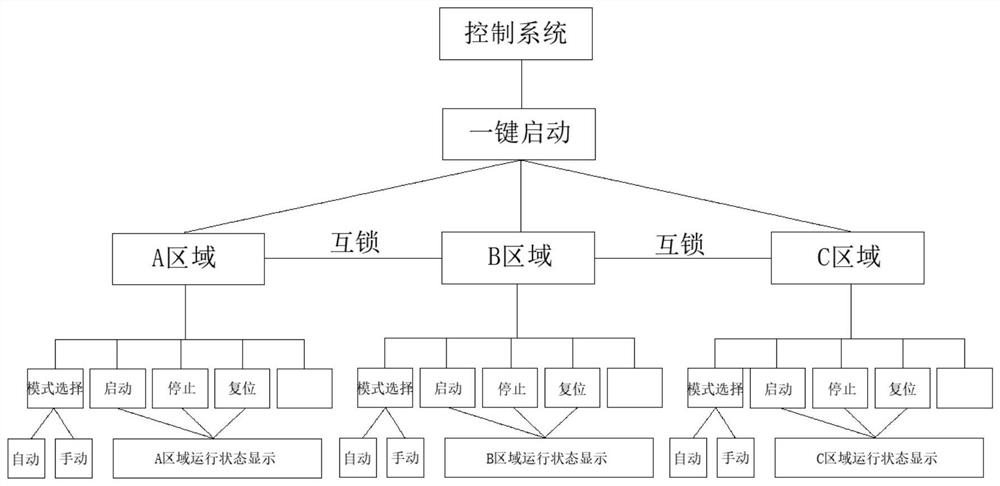

[0030] like figure 1 and figure 2 As shown, the sub-area control system of the chip insertion machine in this embodiment includes a flower basket transfer station control unit, a silicon wafer transfer station control unit, a robot station control unit, and a traverse station control unit; the control unit of one of the stations The unit is the main control unit, the input end of the power supply of the main control unit is used to connect the external power supply, and the output end of the power supply of the main control unit is respectively connected with the power supplies of other station control units; The PN network cable is connected to each other to form a ring network, that is, the control units of each station form a circle. When there is a disconnection, the entire network is also unobstructed, which reduces the failure rate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com