Method for detecting current peak position of switched reluctance motor

A technology of switched reluctance motor and current peak value, applied in the direction of control of electromechanical transmission, control of generator, motor-generator control, etc., can solve the problems of speed fluctuation, large influence, motor running vibration, etc. change-sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

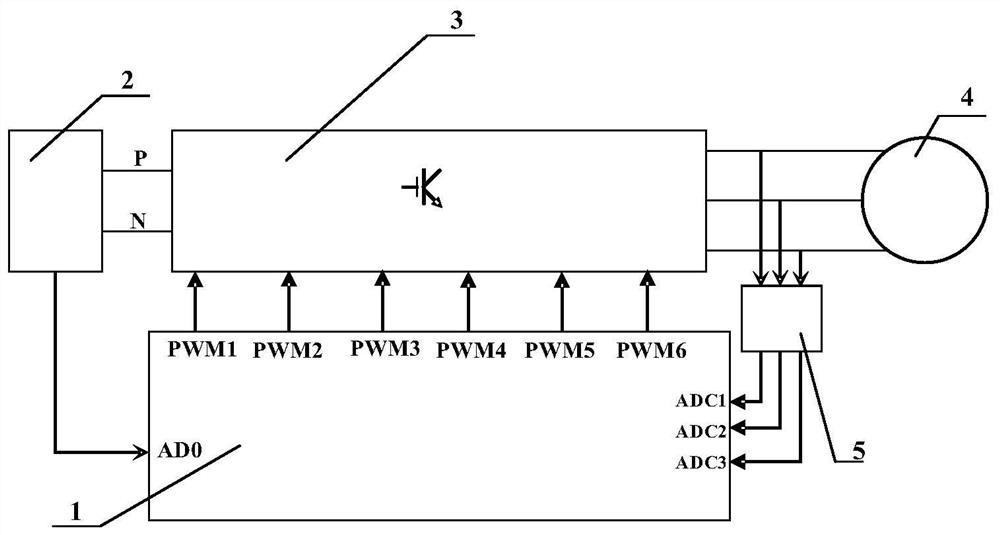

[0027] The specific embodiment of the present invention is as figure 1 As shown, the microcontroller 1 is the DSP chip TMS320F28069 of TI Company, the three-phase rectification and filtering circuit and its bus voltage detection circuit 2 detect the DC bus voltage U of the power converter 3, and input it to the microcontroller 1 after conditioning The ADC0 port of the power converter 3 adopts a three-phase asymmetrical half-bridge structure. The switched reluctance motor 4 is a three-phase switched reluctance motor with 12 / 8 poles, the rated power is 5kW, and the rated speed is 2000r / min. The current is input to the ADC1 port, ADC2 port and ADC3 port of the microcontroller 1 respectively.

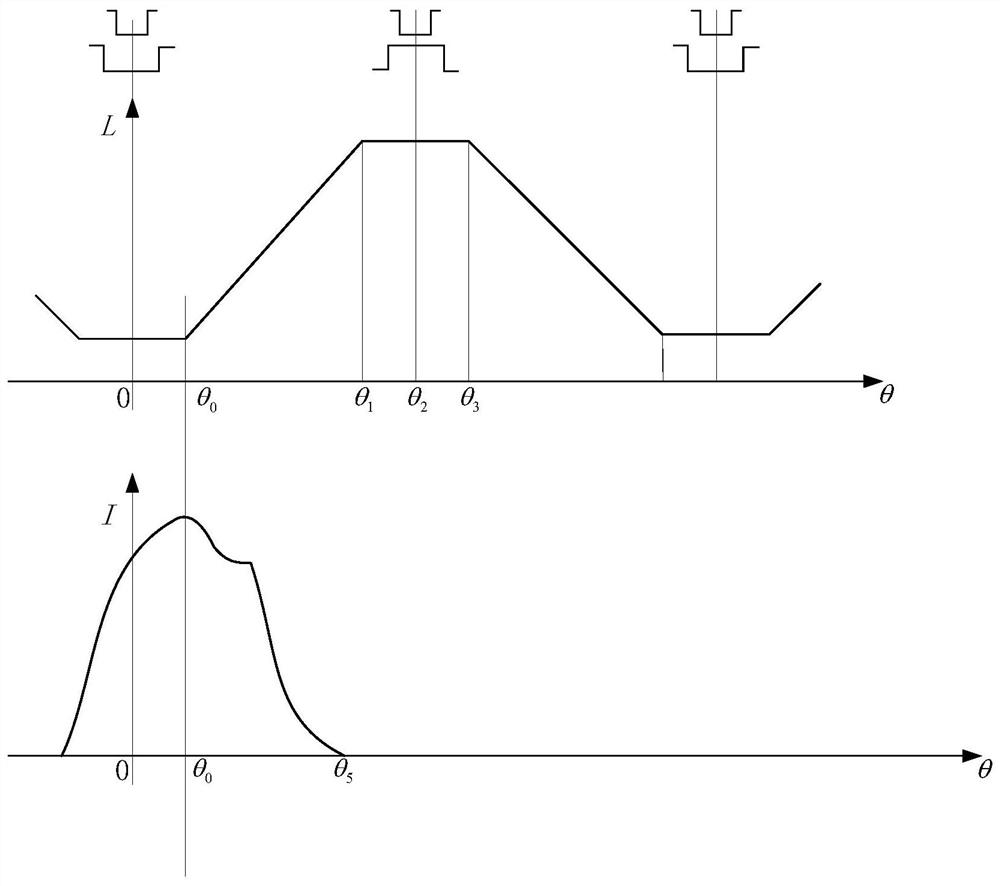

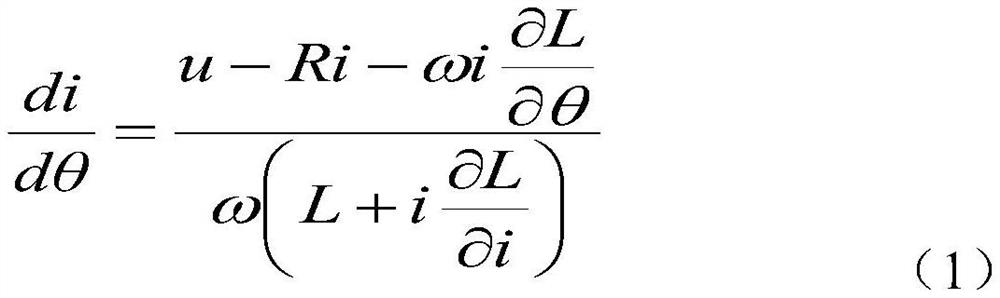

[0028] The switched reluctance motor system adopts the traditional speed and current double closed-loop control without braking for a period of time after the start of power-on operation. The bus voltage detection circuit 2 detects the motor DC bus voltage of the power converter 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com