Method and system for automatically leading and gumming shoe uppers

An automatic guidance and gluing technology, which is applied in the direction of program control manipulators, instruments, calculations, etc., can solve problems such as difficulty in ensuring accuracy and difficulty in obtaining gluing path lines, and achieves improved accuracy and consistency, low requirements, and operator requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

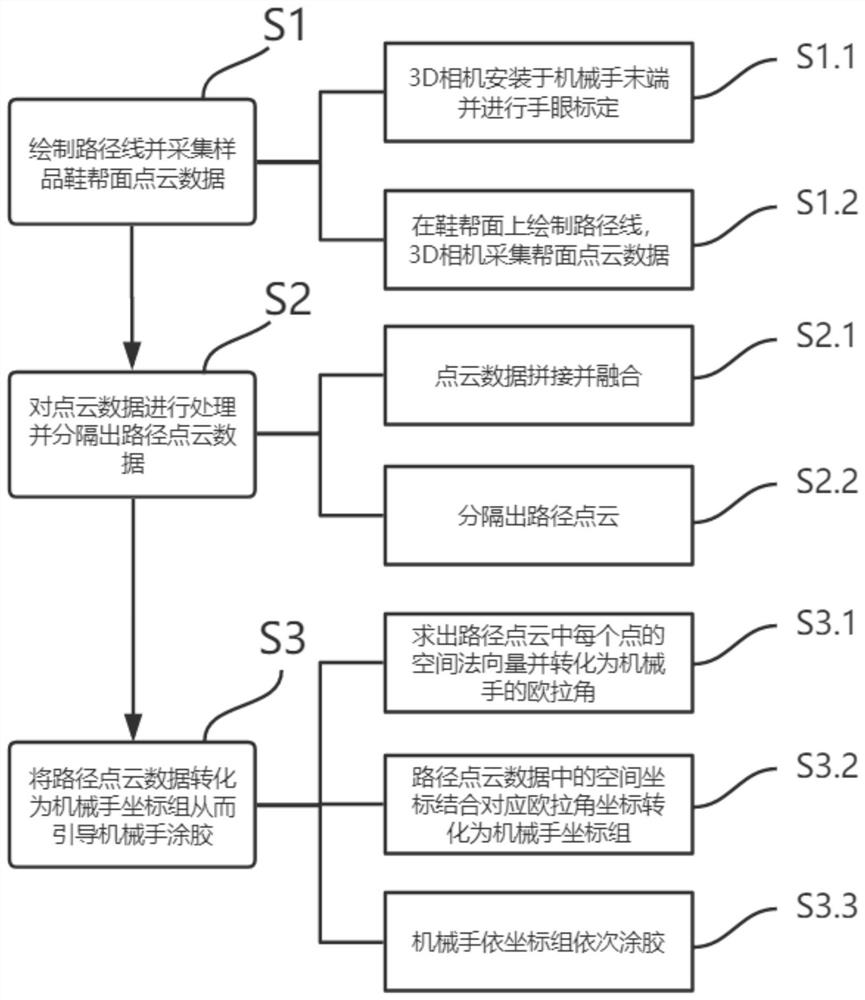

[0042] like figure 1 As shown, a method for automatically guiding gluing on the upper surface, which specifically includes the following steps:

[0043] S1.1, the image acquisition device selects a 3D camera, installs the 3D camera at the end of the manipulator, and performs hand-eye calibration to determine the homogeneous transformation relationship of the 3D camera relative to the end of the manipulator. The hand-eye calibration method is as follows:

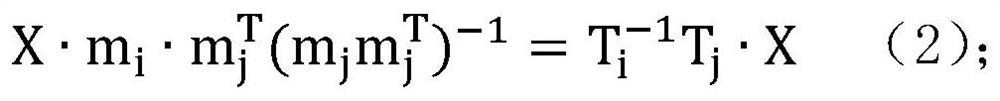

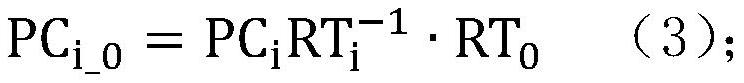

[0044] Rotate the camera to take a fixed cone each time, then the formula is as follows:

[0045] T i ·X·m i =T j ·X·m j (l);

[0046] T in formula (1) i is a 4x4 homogeneous change matrix, indicating the attitude of the end of the manipulator at the i-th time, X is a 4x4 homogeneous change matrix, indicating the installation relationship between the camera and the end of the manipulator, the installation relationship is a fixed value, m i is a 4x1 column vector, which represents the coordinate value of the cone in th...

Embodiment 2

[0092] Embodiment two: a kind of gluing system that adopts the gluing method described in embodiment one, comprising:

[0093] Manipulator, used to automatically apply glue to the upper surface of the shoe;

[0094] A 3D camera that can collect grayscale or RGB information is installed at the end of the manipulator, and the image collection device is used to collect point cloud data of the upper surface of the sample;

[0095] The processors are respectively electrically connected to the 3D cameras, and the processors receive and process point cloud data collected by the 3D cameras and generate a coordinate group that can be recognized by the manipulator.

[0096] The above-mentioned technical solutions in the embodiments of the present application have at least the following technical effects or advantages:

[0097] 1. This method pre-draws the path line on the upper surface, and then drives the image acquisition device to obtain the point cloud data of the sample upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com