Resin-based thermal transfer printing ribbon high in universality and manufacture method thereof

A thermal transfer ribbon and resin-based technology, applied in the field of resin-based thermal transfer ribbon and its preparation, can solve problems such as a large variety of inventory, and achieve the effects of wide use, excellent media applicability, and low printing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

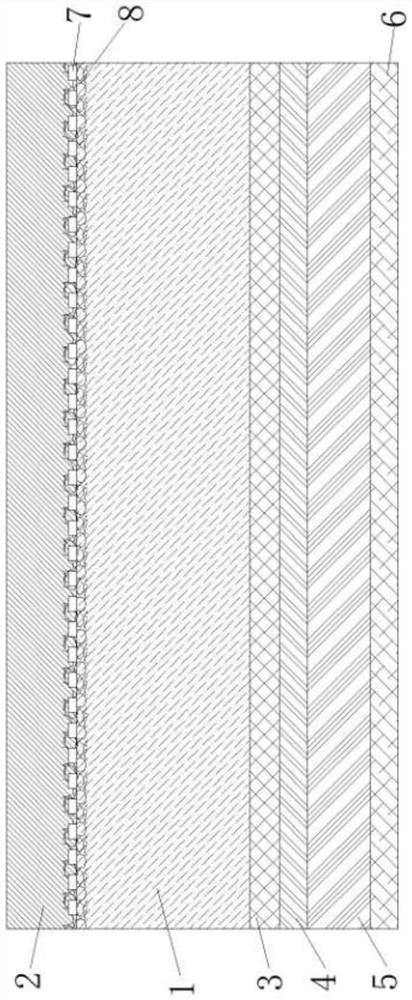

[0062] A resin-based thermal transfer ribbon with strong versatility, including a base belt made of a biaxially stretched polyester film without corona treatment with a thickness of 4.3-4.5 microns, and an anti-corrosion coating uniformly coated on the base belt by gravure printing Thermal ink layer, release layer, protective layer, coloring layer and adhesive layer.

[0063] The release layer is composed of 92-97 parts by weight of carnauba wax, 2-5 parts by weight of petroleum resin, and 2-5 parts by weight of EVA. The preparation and coating method of the release layer is: firstly mix the Brazilian wax, petroleum resin and EVA evenly under the condition of heating; Distributed on the base film, the amount of ink loaded is controlled at 0.5-1.0g / m 2 .

[0064] The protective layer is composed of 15-25 parts by weight of acrylic resin, 5-15 parts by weight of CAB, 40-60 parts by weight of butyl ester, and 20-30 parts by weight of ethyl ester. The preparation and coating me...

Embodiment 2

[0068] A resin-based thermal transfer ribbon with strong versatility, including a base belt made of a biaxially stretched polyester film without corona treatment with a thickness of 4.3-4.5 microns, and an anti-corrosion coating uniformly coated on the base belt by gravure printing Thermal ink layer, release layer, protective layer, coloring layer and adhesive layer.

[0069] The release layer is composed of 60-70 parts by weight of carnauba wax, 20-30 parts by weight of Fischer-Tropsch wax, and 2-5 parts by weight of EVA. The preparation and coating method of the release layer is: first mix the Brazilian wax, Fischer-Tropsch wax and EVA evenly under the condition of heating; Coated on the base film, the amount of ink loaded is controlled at 0.5-1.0g / m 2 .

[0070] The protective layer is composed of 15-25 parts by weight of acrylic resin, 5-15% by weight of CAP, 40-60 parts by weight of butyl ester, and 20-30 parts by weight of ethyl ester. The preparation and coating meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com