3D printed heart stent for cardiac interventional surgery

A 3D printing and interventional surgery technology, applied in the medical field, can solve the problems of increasing the risk of thrombosis in the stent, damage to the structure and function of the intradermal cells, and fracture of the stent wire. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The weight components of the 3D printed heart stent for cardiac interventional surgery are: 70 parts of poly-L-lactic acid, 15 parts of ethyl cellulose, 5 parts of starch, 3 parts of superfine calcium carbonate, 2 parts of sodium stearate, epoxy large 1 part soybean oil.

[0037] Preparation of printing paste:

[0038] (1) Dissolving poly-L-lactic acid in chloroform and stirring at room temperature for 3.5 hours to obtain a homogeneous poly-L-lactic acid solution;

[0039] (2) Mix ethyl cellulose, starch, superfine calcium carbonate, sodium stearate and epoxidized soybean oil and pour it into the poly-L-lactic acid solution in step (1), add pure water, tributylmethyl ether and 2, 2-dimethoxypropane, after fully stirring and mixing, filter, concentrate at 60°C to a thick paste with a density of 1.15, put it into a high-speed vibrating ball mill and grind for 10 hours, and then use a constant temperature magnetic stirrer to stir at 37°C Mix evenly for 20 minutes, and th...

Embodiment 2

[0045] The weight components of the 3D printed heart stent for cardiac interventional surgery are: 80 parts of poly-L-lactic acid, 15 parts of polyvinyl alcohol, 7 parts of starch, 5 parts of calcium silicate, 3 parts of sodium stearate, and 4 parts of phosphite .

[0046] Preparation of printing paste:

[0047] (1) Dissolving poly-L-lactic acid in chloroform and stirring at room temperature for 3 hours to obtain a homogeneous poly-L-lactic acid solution;

[0048] (2), mix polyvinyl alcohol, starch, calcium silicate, sodium stearate and phosphite, pour it into the poly-L-lactic acid solution in step (1), add pure water, tributylmethyl ether and 2,2 - Dimethoxypropane, after fully stirring and mixing, filter, concentrate at 60°C to a thick paste with a density of 1.18, put it into a high-speed vibrating ball mill and grind for 11.5 hours, and then use a constant temperature magnetic stirrer to stir and mix at 37°C 25min, the rotating speed is 1000rpm when stirring, and the pr...

Embodiment 3

[0054] The weight components of the 3D printed heart stent for cardiac interventional surgery are: 91 parts of poly-L-lactic acid, 20 parts of polyvinyl acetate, 12 parts of starch, 7 parts of ultrafine barium sulfate, 5 parts of polyethylene wax, and 6 parts of hindered phenol.

[0055] Preparation of printing paste:

[0056] (1) Dissolving poly-L-lactic acid in chloroform and stirring at room temperature for 4.5 hours to obtain a homogeneous poly-L-lactic acid solution;

[0057] (2) Mix polyvinyl acetate, starch, superfine barium sulfate, polyethylene wax and hindered phenol into the poly-L-lactic acid solution in step (1), add pure water, tributylmethyl ether and 2,2- Dimethoxypropane, after fully stirring and mixing, filtered, concentrated at 60°C to form a thick paste with a density of 1.2, put it into a high-speed vibrating ball mill for grinding for 11 hours, and then used a constant temperature magnetic stirrer to stir and mix at 37°C for 27 minutes. The rotational sp...

PUM

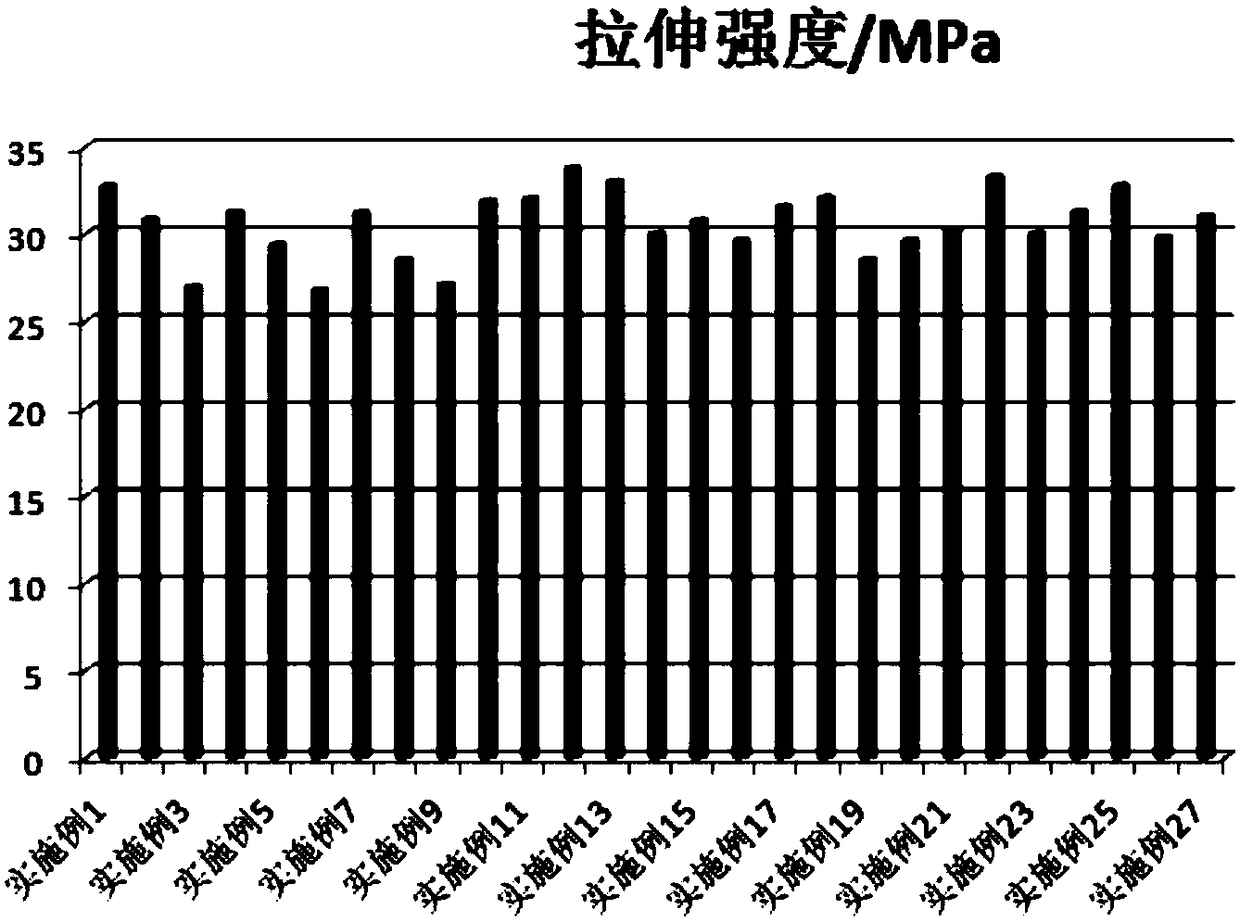

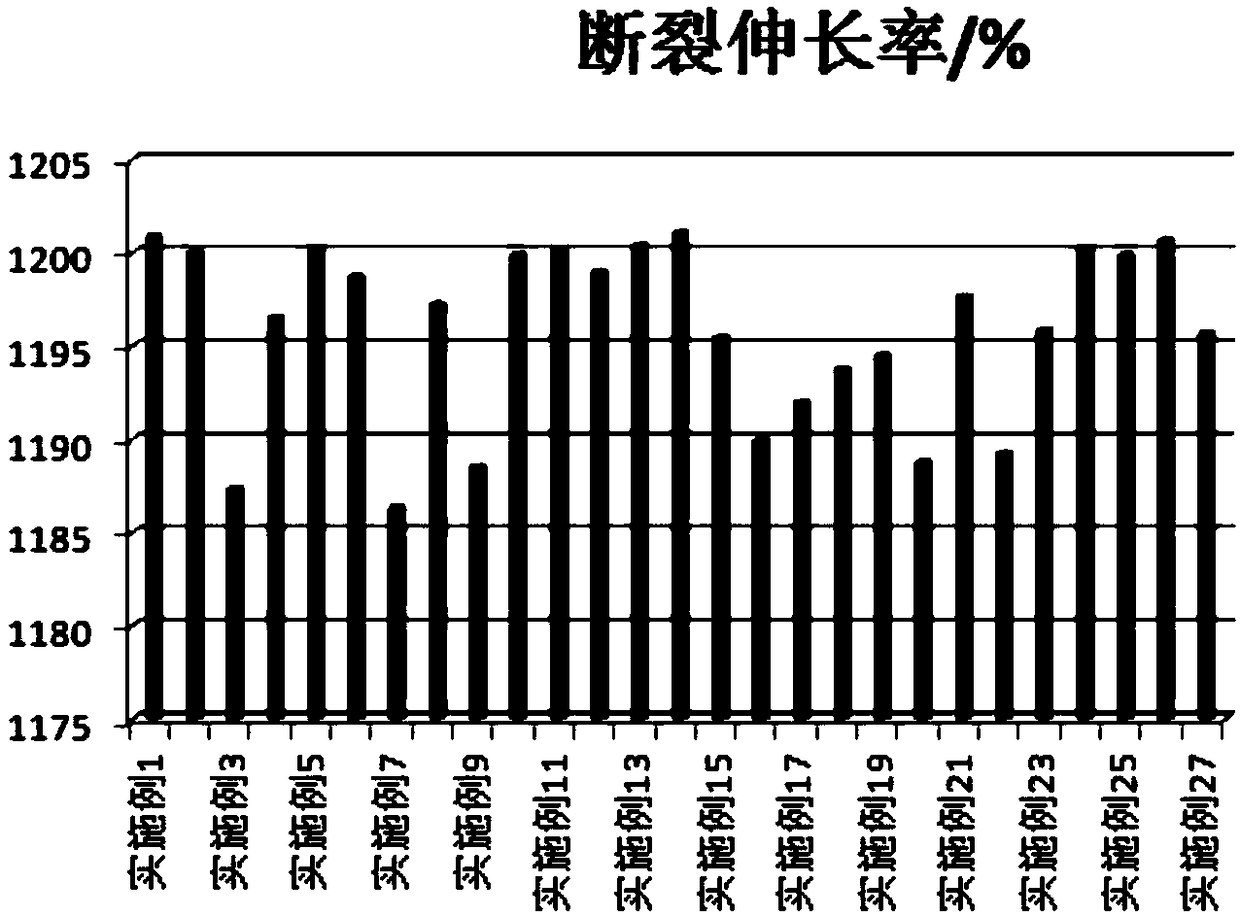

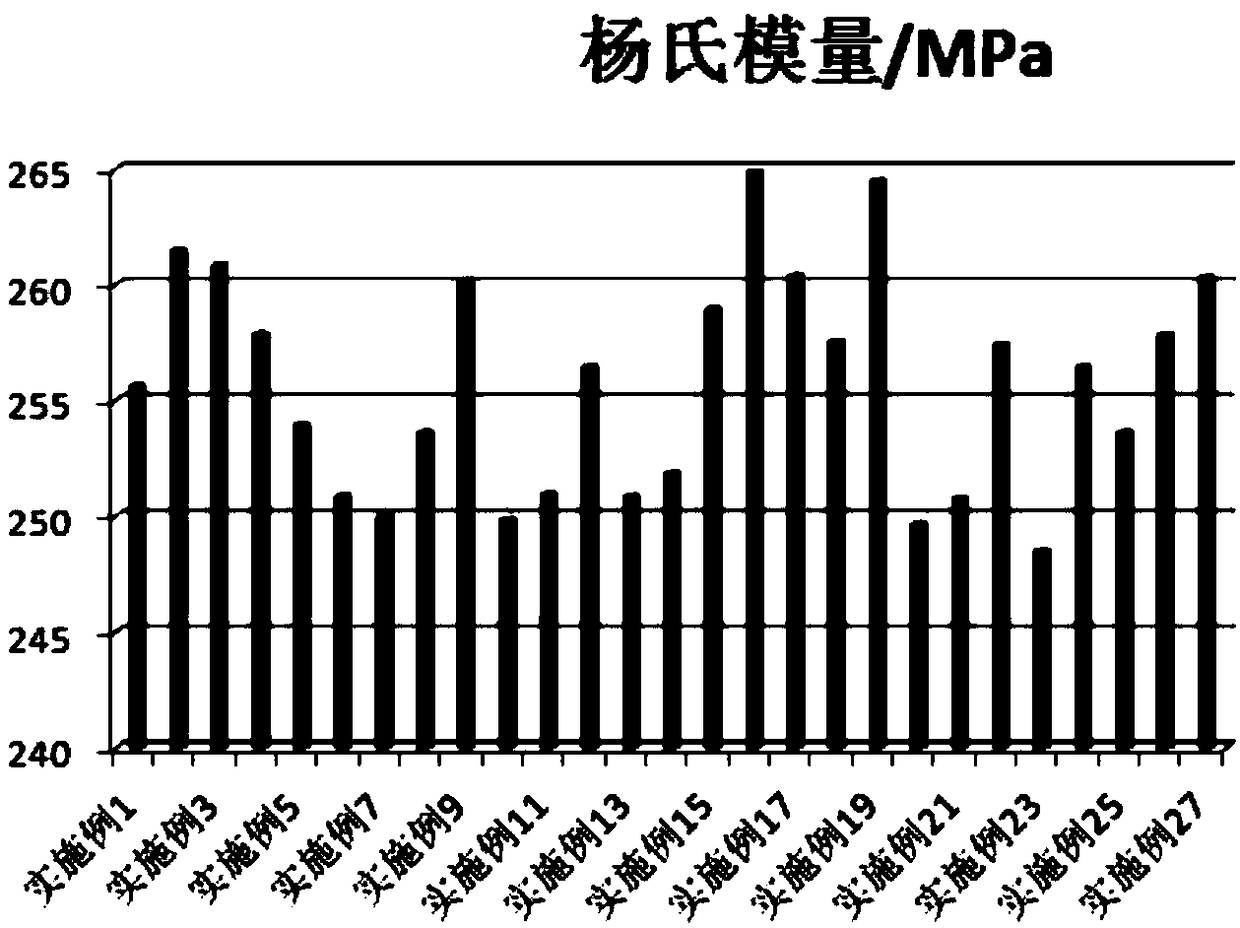

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com