Circulating bioreactor for livestock and poultry breeding sewage treatment

A bioreactor and sewage treatment technology, which is applied in animal husbandry wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of reduced sealing of feed inlet, mixing of new and old materials, and reaction of new materials Insufficient and other problems, to achieve the effect of ensuring the internal environment, improving feeding efficiency, and constant internal sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

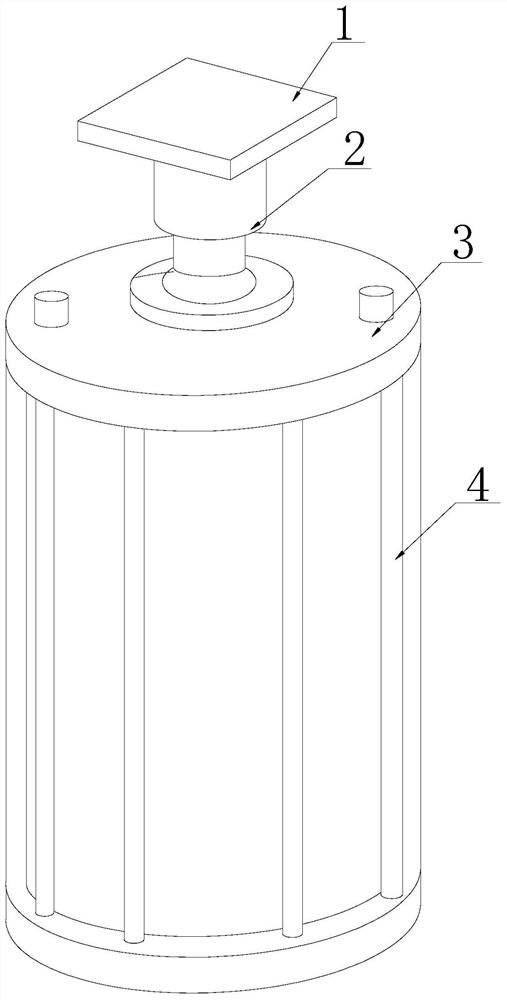

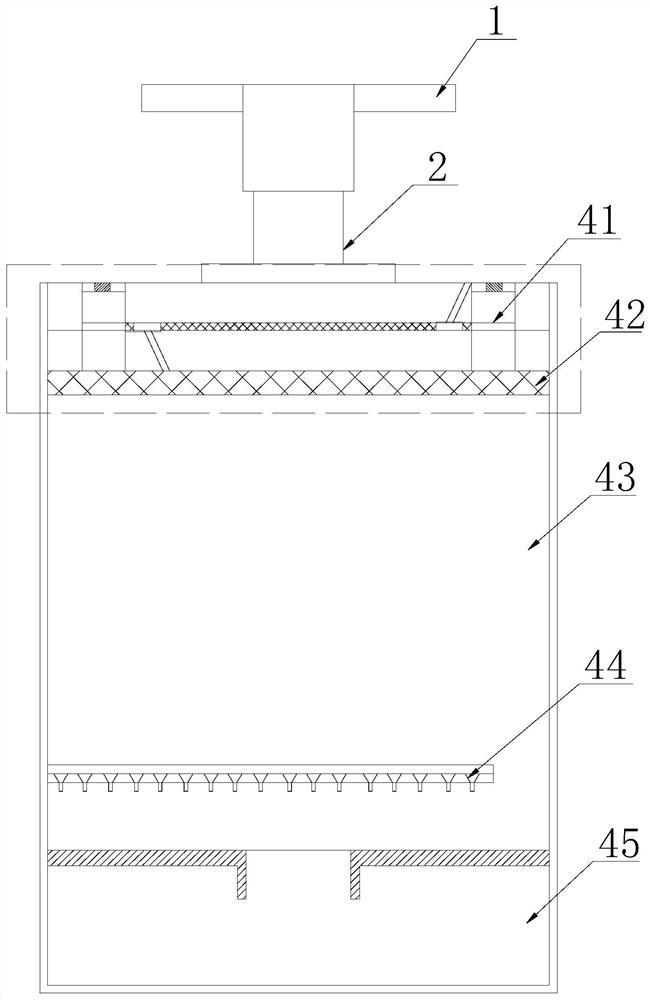

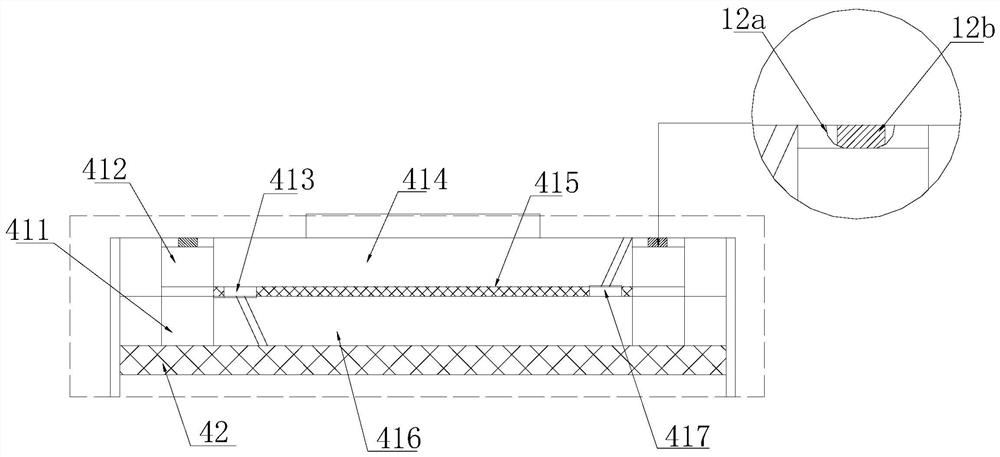

[0037] Such as Figure 1-Figure 3As shown, the present invention provides a circulating bioreactor for livestock and poultry breeding sewage treatment, its structure includes an end cover 1, an air collecting pipe 2, an outer frame 3, and a reaction cylinder 4, and the end cover 1 is installed on the air collecting pipe 2, the gas collecting pipe 2 extends inside the reaction cylinder 4, the surface of the reaction cylinder 4 is provided with an outer frame 3, and the inside of the reaction cylinder 3 is composed of a discharge mechanism 41, a biological filler tank 42. Reaction chamber 43, backwash pipe 44, mud discharge port 45, the discharge mechanism 41 is installed on the upper end of the biological filler tank 42, and the biological filler tank 42 and the backwash pipe 44 are both arranged inside the reaction chamber 43 , the mud discharge port 45 is located at the bottom of the reaction chamber 43, and the two are an integrated structure, the discharge mechanism 41 is c...

Embodiment 2

[0039] Such as Figure 4-Figure 5 As shown, on the basis of Embodiment 1, through the mutual cooperation of the following structural components, the second slider 417 includes a swing scraper 17a, a clip 17b, a balance wheel 17c, a mounting seat 17d, a swing rod 17e, a hinge Head 17f, the swing scraper 17a is movably connected to the mounting seat 17d through the balance wheel 17c, the clips 17b are mechanically connected between the two sides of the swing scraper 17a and the mounting seat 17d, and the hinged head 17f is set On both sides of the mounting seat 17d, the swing rod 17e is swung through the hinge joint 17f to fit on the horizontal position where the clip 17b extends out of the mounting seat 17d, and the swing rod 17e cooperates with the hinge joint 17f to push the clip 17b out of the material Collect and recycle.

[0040] The partition 415 is provided with a first notch 15a, a slider 15b, a pressure chamber 15c, and a second notch 15d. The second notch 15d is mova...

Embodiment 3

[0043] Such as Figure 6-Figure 8 As shown, on the basis of combining Embodiment 1 and Embodiment 2, through the mutual cooperation of the following structural components, the swinging scraper 17a includes a connecting shaft 7a1, a ball 7a2, a supporting slide 7a3, a slot 7a4, and a block 7a5, the stroke sphere 7a2 is provided with two, fixed by a connecting shaft 7a1 between them, the stroke sphere 7a2 is fixed on the inner walls of both sides of the swinging scraper 17a through the support slide 7a3, and the groove 7a4 is provided with two A block 7a5 engaged with the ball 7 is used to limit the horizontal movement distance of the ball 7 by the block 7a5.

[0044] The stroke sphere 7a2 includes a running wheel a21, a stroke piece a22, an engaging bracket a23, a base a24, a slide bar a25, a pressing block a26, and a connecting rod a27. The surface of the running wheel a21 is welded with four evenly distributed connecting rods a27, The connecting rod a27 is fixed to the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com