Supersonic wind tunnel propeller numerical model measurement and verification system and control method thereof

A technology for verifying systems and numerical models. It is used in measurement devices, aerodynamic tests, and testing of machine/structural components. It can solve the problems of inability to simulate propellers of different specifications, interference of propellers in supersonic wind tunnels, and high manufacturing costs. , to achieve the effect of simple structure, excellent performance conditions and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

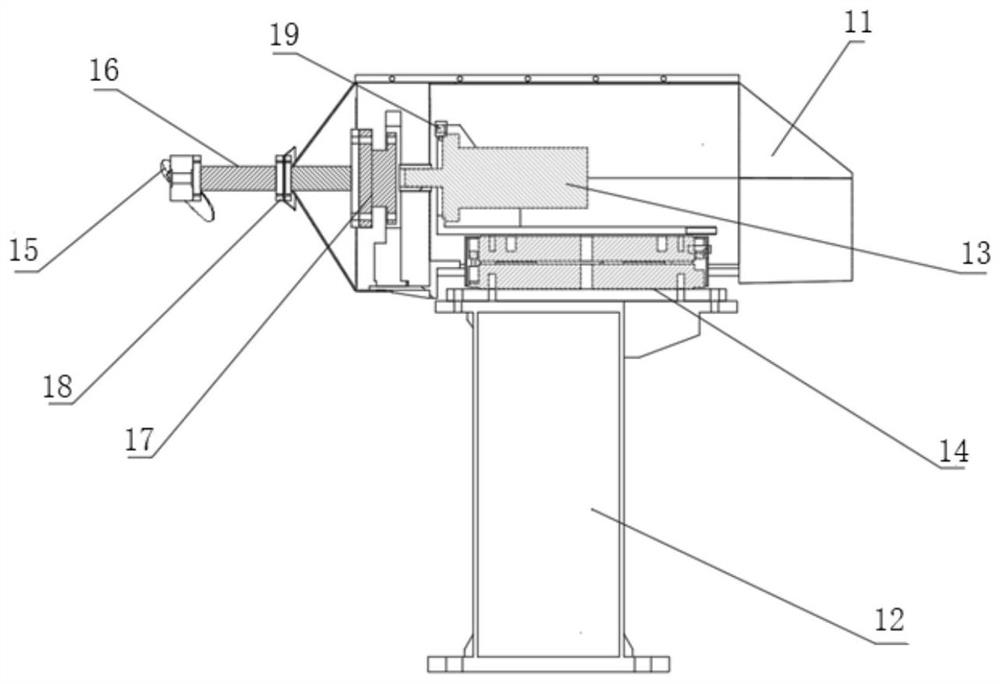

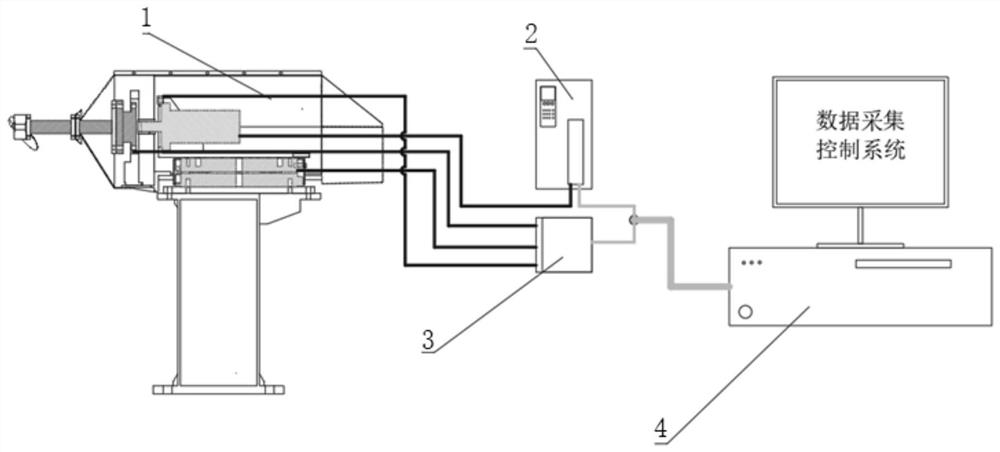

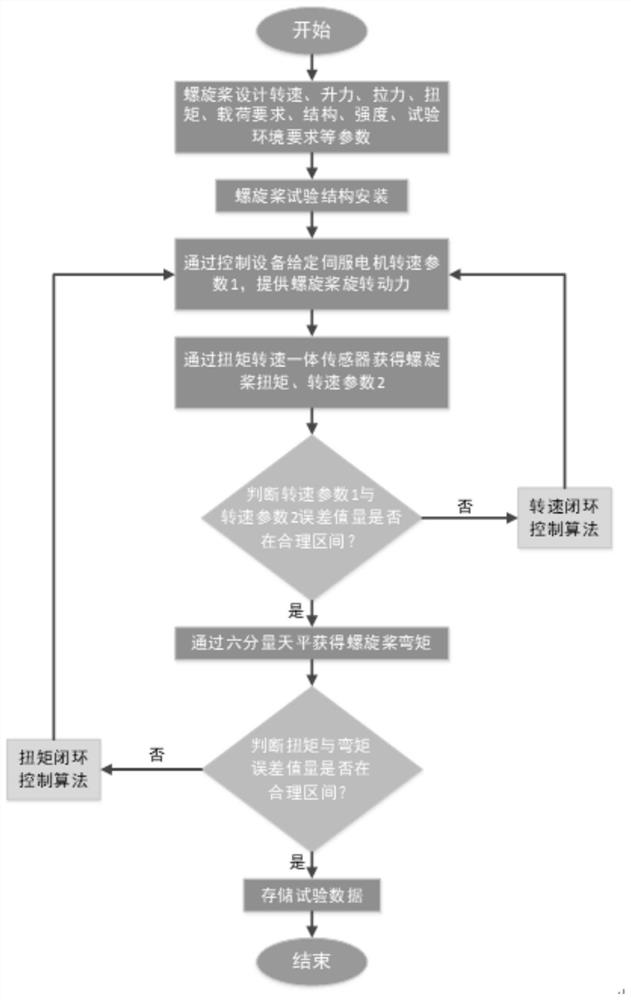

[0032] Such as Figure 1-2 As shown, a supersonic wind tunnel propeller numerical model measurement verification system, the measurement verification system includes:

[0033] Different specification propeller multifunctional measuring device 1, described different specification propeller multifunctional measuring device 1 comprises box-type six-component balance 14, drive shaft 16, and described box-type six-component balance 14 is provided with servo motor 13, and described servo motor 13 The output shaft is connected to the drive shaft 16 through a spline, and the drive shaft 16 is surrounded by a torque speed sensor 17, and the front end of the drive shaft 16 is connected to propellers 15 of different specifications through flanges;

[0034] PLC control unit 2, data acquisition module 3 and PC 4, the PC 4 is used to control the PLC control unit 2 to drive the servo motor 13 in the propeller multifunctional measurement device 1 of different specifications to provide the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com