co 2 Obtaining method of blasting strain energy conversion coefficient and equivalent explosive calculation formula

A technology of conversion coefficients and calculation formulas, which is applied in the directions of material explosiveness, complex mathematical operations, ammunition, etc., and can solve problems such as energy waste in blasting rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

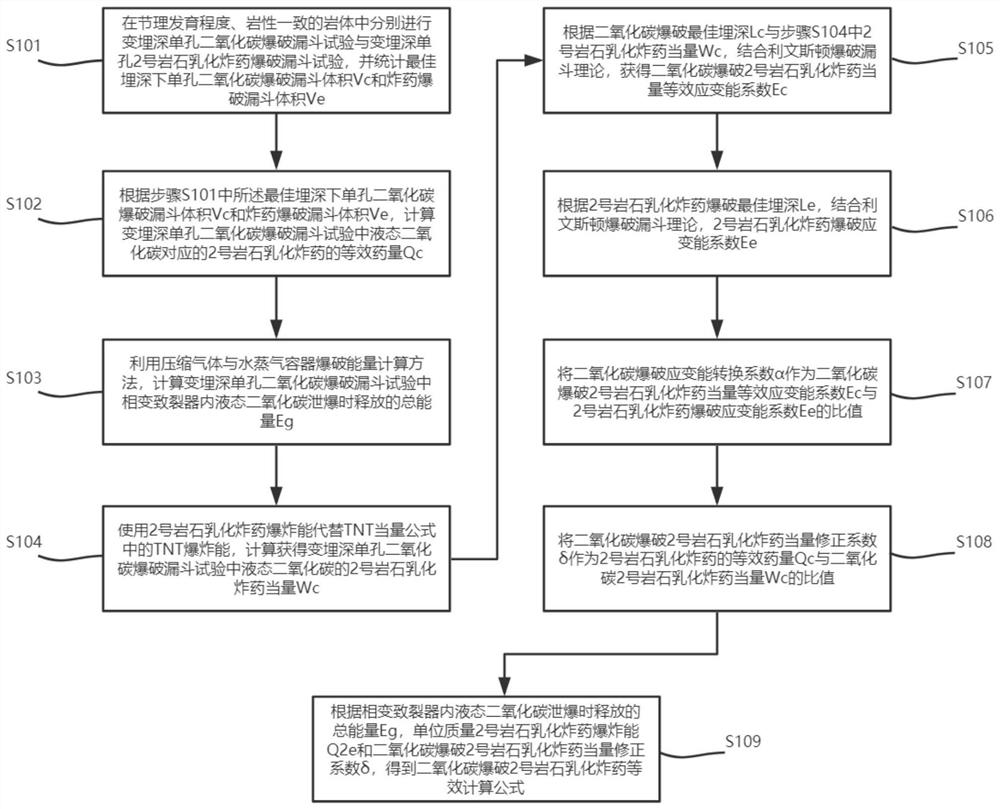

[0038] Please refer to figure 1 , an embodiment of the present invention provides CO 2 The method for obtaining the blasting strain energy conversion coefficient and equivalent explosive calculation formula includes the following steps:

[0039] S101: In the rock mass with the same degree of joint development and lithology, conduct the funnel test of carbon dioxide blasting funnel with variable buried depth and No. 2 rock emulsion explosive blasting with single hole with variable buried depth, and count the single hole carbon dioxide at the optimal buried depth Blasting funnel volume V c and the explosive blasting funnel volume V e ; The optimal buried depth includes the optimal buried depth L for carbon dioxide blasting c and No. 2 rock emulsion exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com