LED chip based on graphical reflector and manufacturing method of LED chip

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of low front light output rate, etc., and achieve the effect of improving light output efficiency, improving reflectivity, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

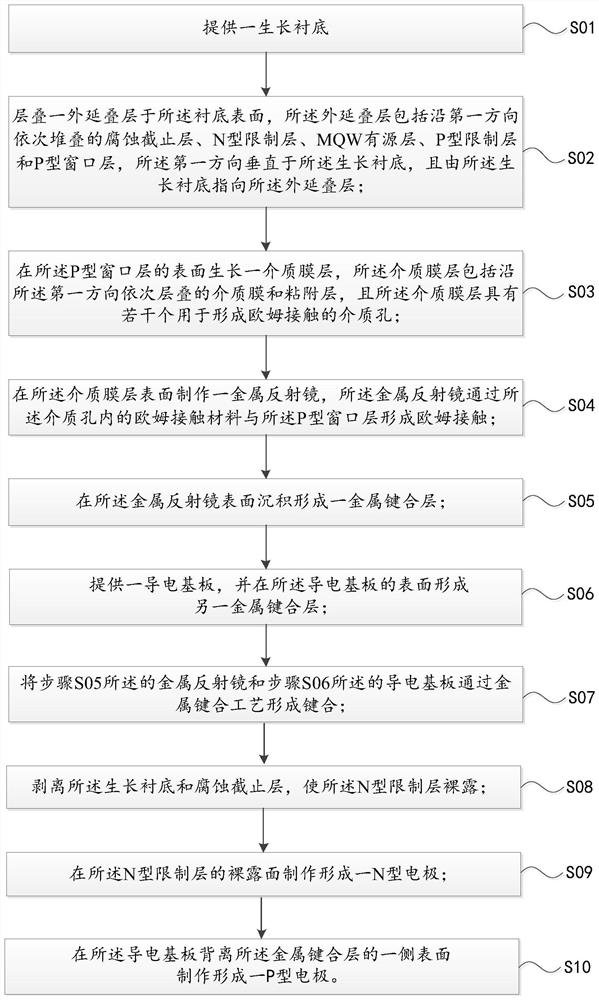

[0053] Such as figure 1 As shown, a method for manufacturing an LED chip based on a patterned reflector includes the following steps:

[0054] S01. Provide a growth substrate A;

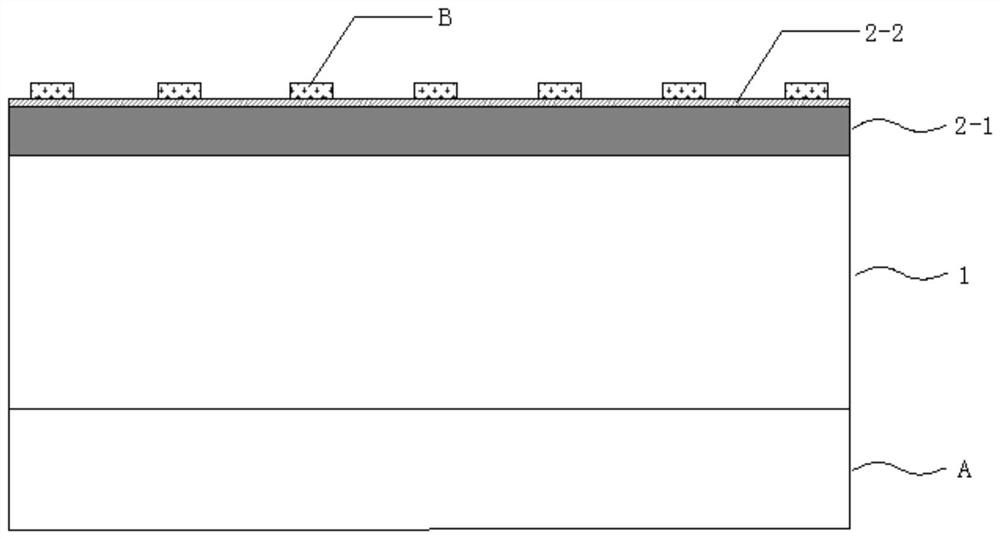

[0055] S02. Laminate an epitaxial stack 1 on the surface of the growth substrate A. The epitaxial stack 1 includes an etch stop layer, a first-type confinement layer 1-2, an active layer 1-3, and a second-type confinement layer stacked in sequence along the first direction. Confinement layers 1-4 and second-type window layers 1-5, the first direction is perpendicular to the growth substrate, and the growth substrate points to the epitaxial stack 1;

[0056] In the embodiment of the present invention, as an optional embodiment, the fabrication of the epitaxial stack further includes sequentially fabricating a buffer layer, an etch stop layer, a roughening layer, a first-type confinement layer, an active layer, The second-type confinement layer and the second-type window layer; the function of the bu...

Embodiment 2

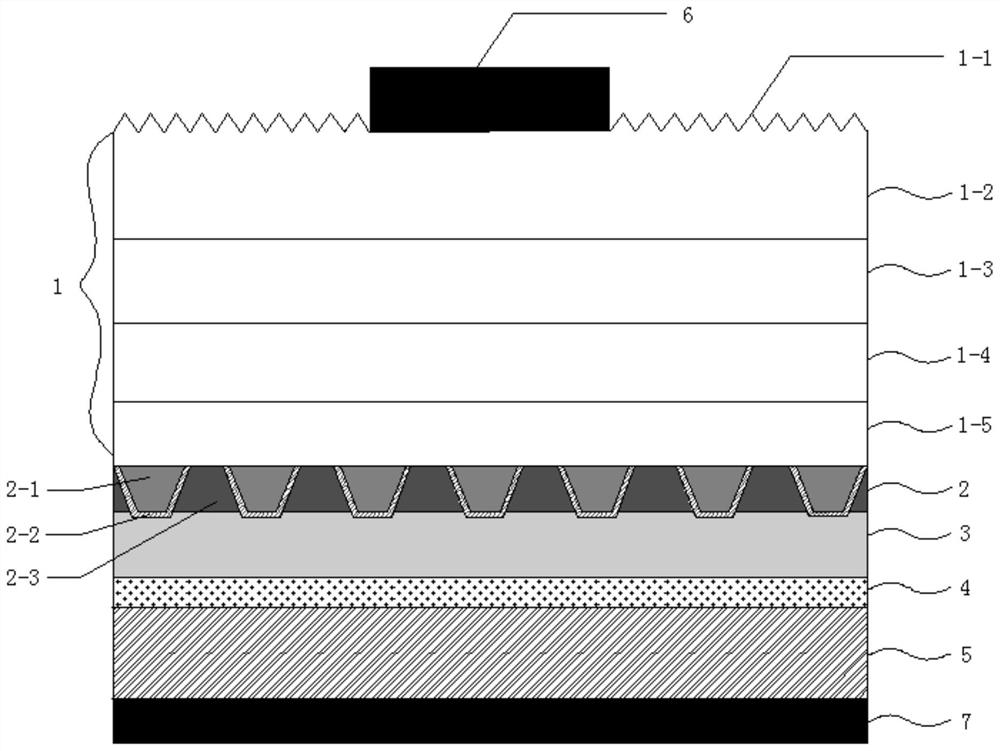

[0095] On the basis of the above-mentioned embodiments, the embodiment of the present invention also provides an LED chip based on a patterned reflector, which is manufactured based on the manufacturing method described in Embodiment 1, and its structural diagram can be referred to figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com