A Rotary Tool Electrode for Electromelting Explosion Machining of Special-shaped Hole with Large Length-to-Diameter Ratio

A technology of large aspect ratio and tool electrode, which is applied in the direction of electric processing equipment, manufacturing tools, electrode manufacturing, etc., can solve the problems of chip removal, cooling difficulty, electrode preparation difficulty, etc., and achieve simple and practical electrode structure, good manufacturability, The effect of strengthening the degree of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

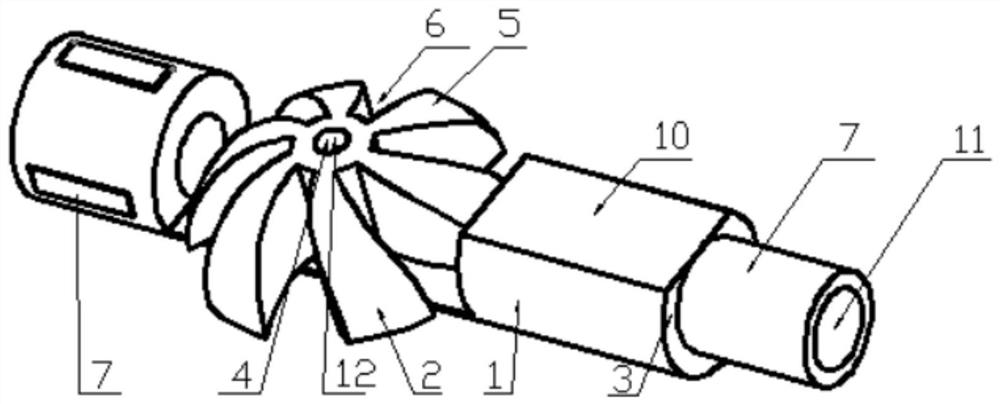

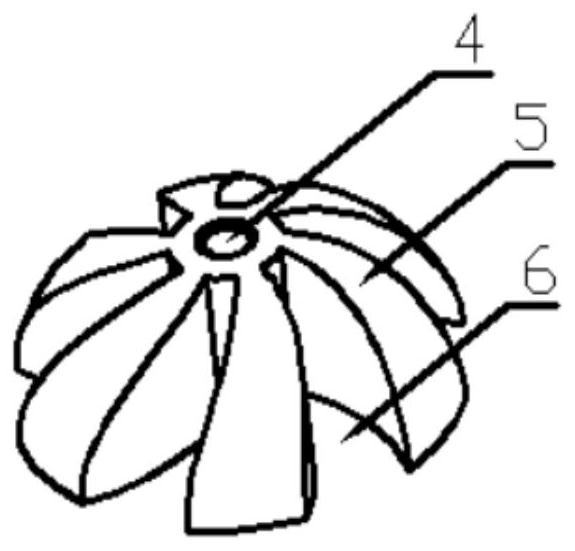

[0033] The rotary tool electrode of the invention for the electrofusion and blasting process of the special-shaped hole with a large aspect ratio adopts a blade-type rotary structure, and the guide strip is preceded by an insulating layer. The chip body is carried out of the body through the gap between the blades, which greatly improves the ability of chip removal and cooling, and ensures the processing quality.

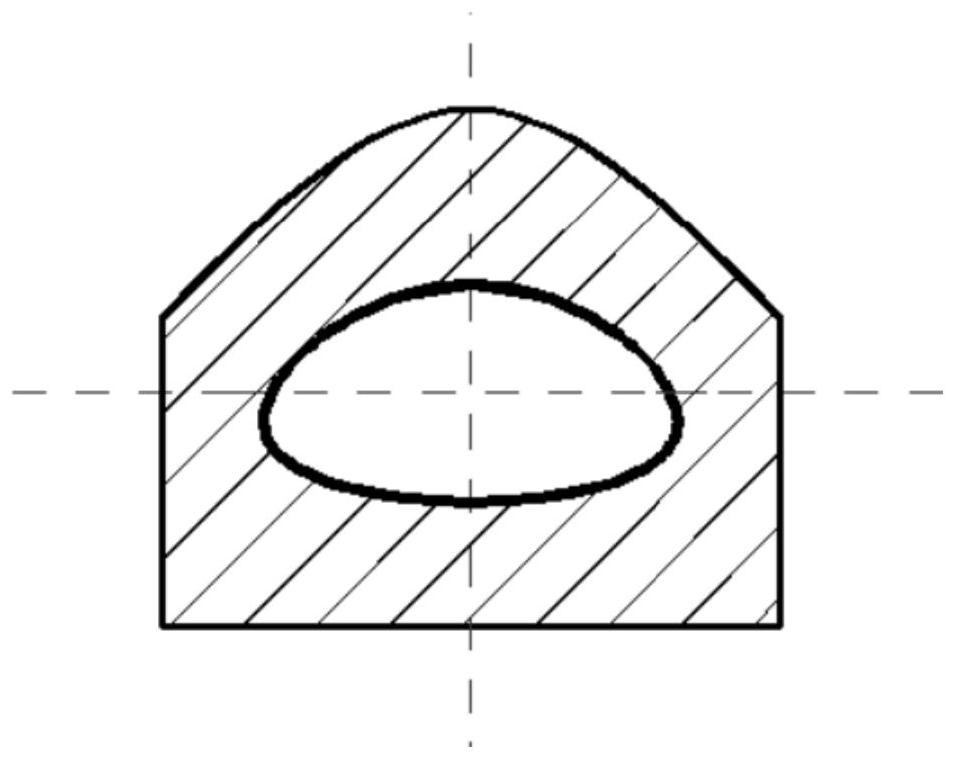

[0034] The special-shaped holes that can be processed by the present invention are irregular oval holes, such as figure 1 shown.

[0035] The structure of the invention adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com