Pre-shrinking equipment for processing new material film

A material film, pre-shrinking technology, applied in the direction of wrapping paper shrinkage, packaging machine, packaging, etc., can solve the problems of difficulty in mass production of printed shrink film packaging products, poor packaging effect of plastic film, uneven shrinkage of plastic film, etc. Achieve the effect of improving the accuracy of lamination, keeping clean, and holding firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

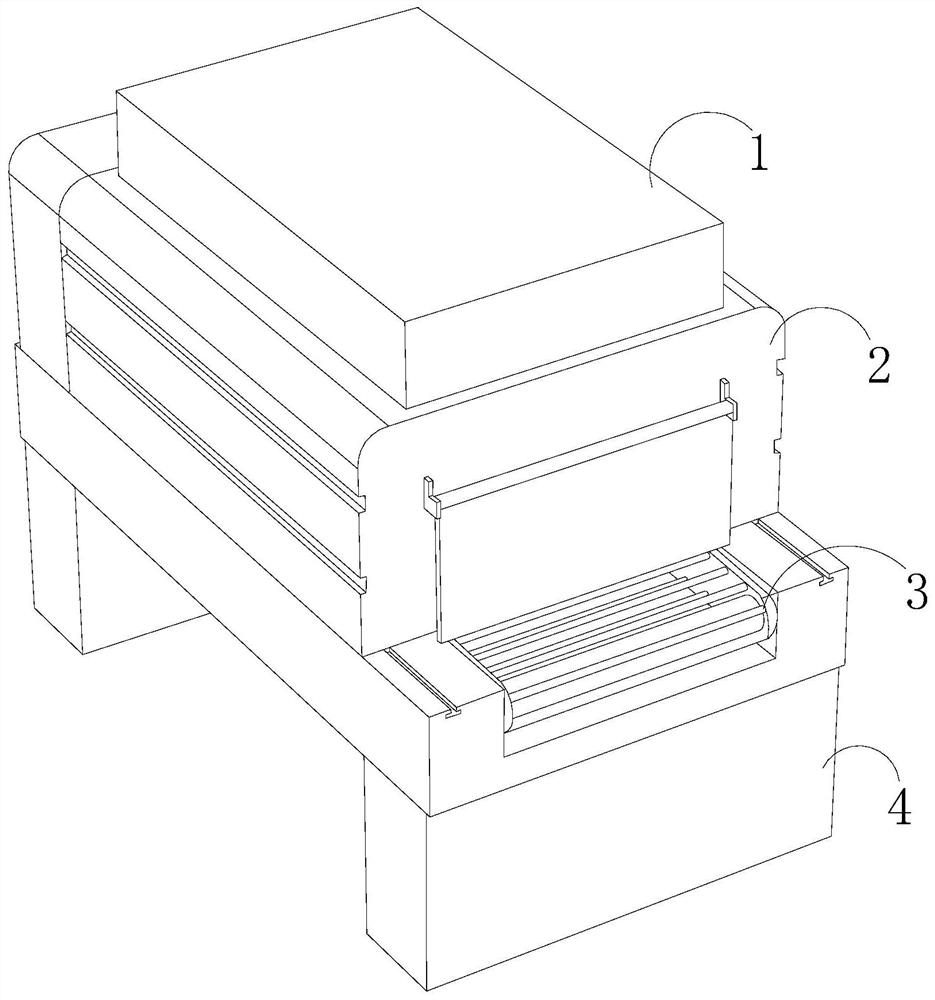

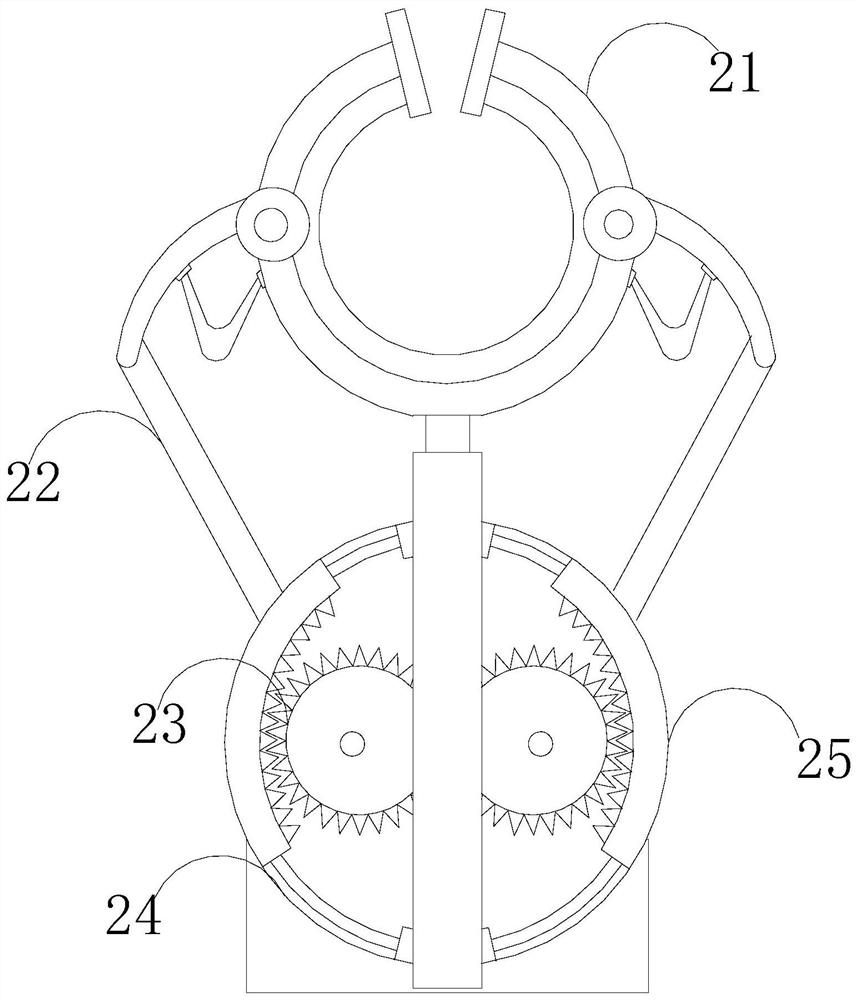

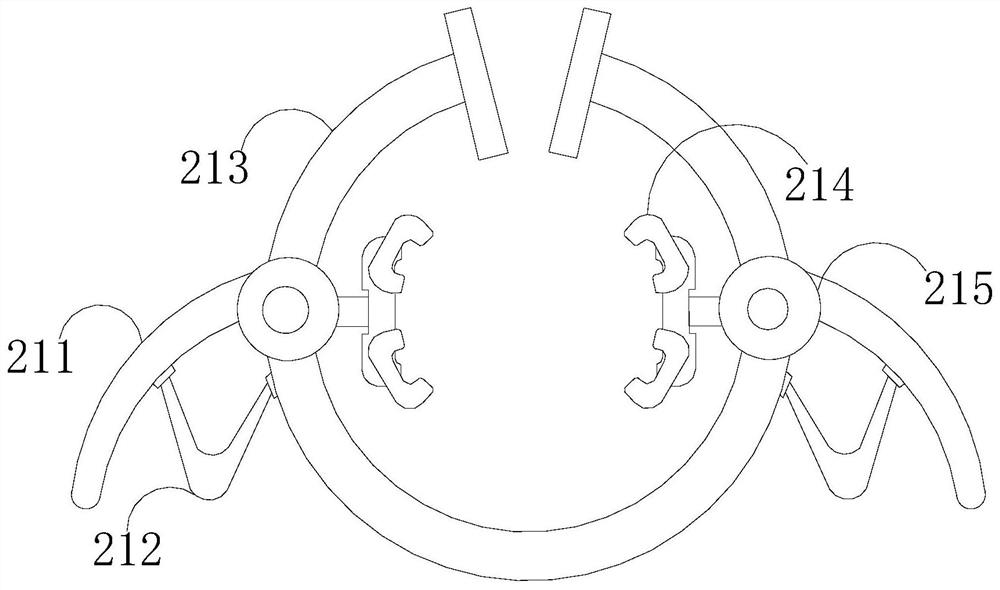

[0036] Such as Figure 1-Figure 5As shown, the present invention provides a kind of pre-shrinking equipment for new material film processing. Belt 3, a bracket 4 is installed at the bottom of the shrinking main body 2, and is matched with the transmission belt 3. The inside of the shrinking main body 2 mainly includes a fixing device 21, a support rod 22, a gear 23, a guide rail 24, and a slider 25. The fixing device 21 cooperates with the slider 25 through the support rod 22. The inner side of the slider 25 is a rack structure, and cooperates with the gear 23 in a manner of meshing connection, and the gear 23 is connected with the guide rail 24 through a sliding fit. , the fixing device 21 is composed of a handle 211, an elastic member 212, a fixed block 213, a clamping device 214, and a fixed point member 215. An elastic member 212 is fixedly connected between the surface of the handle 211 and the surface of the fixed block 213. The inside of the fixed block 213 is movably ...

Embodiment 2

[0038] Such as Figure 6-Figure 10 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The wind direction adjustment device 1 mainly includes a motor 11, a telescopic rod 12, a connector 13, a guide groove 14, a connecting rod 15, and a rotator 16. Support base 17, blade 18, connecting shaft 19, telescopic rod 12 is connected to the bottom of the motor 11, and the telescopic end of the telescopic rod 12 is connected to the connector 13, and one end of the connector 13 is provided with a guide groove 14 and a telescopic The telescopic end of the rod 12 is slidingly fitted, and the other end of the connector 13 is provided with a through hole through the connecting rod 15 to movably cooperate with the rotator 16, and the rotator 16 is connected to the connecting shaft 19 by means of bolt connection, and the support seat 17 is installed at both ends of the connecting rod 15, the connecting shaft 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com